Have you ever stopped to realize just how ubiquitous compressed air is in our daily lives? Whether you’re relaxing at a ski resort that relies on snow machines or getting your car serviced, air compressors are silently contributing behind the scenes. But their reach extends well beyond these scenarios, playing a vital role across numerous industries and everyday applications. Let’s explore the various ways air compressor are used and why they’re such an indispensable resource.

Contents

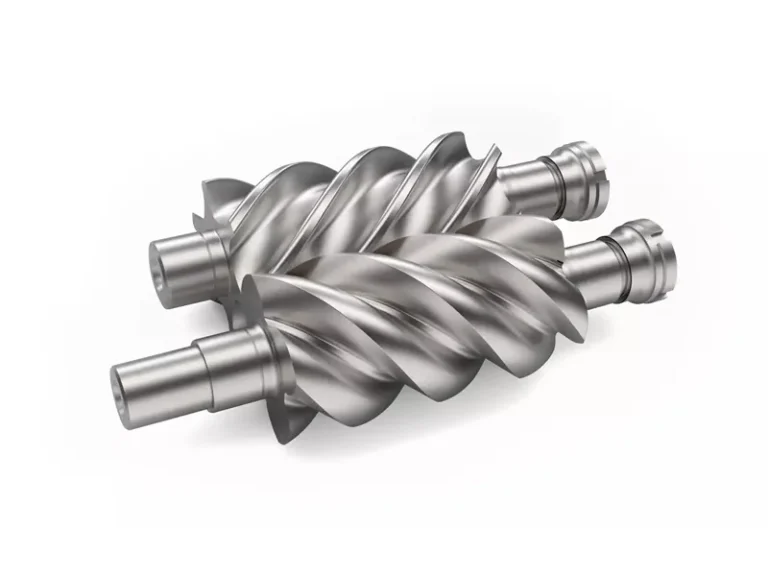

Compressed Air: Powering Processes and Machinery

At its core, air compressor is a powerful tool for driving machinery, operating equipment, and supporting complex industrial processes. Industries and individuals utilize it across a wide range of sectors, including manufacturing, automotive, entertainment, DIY projects, and even dry cleaning.

In industry, air compressor is typically applied in two primary ways:

- Energy Air: Used to store and transmit energy, this type powers pneumatic production equipment, actuates tool chucks, cleans parts under pressure, and conveys or cools components during manufacturing.

- Active Air: This type of air comes into direct contact with the product. In such cases, air purity is critical. High-quality air—clean, dry, and oil-free, often achieved via special compressors along with filtration and drying systems—is essential to maintain product integrity.

Everyday Applications: Where Compressed Air Makes a Difference

Even when we don’t realize it, air compressor is at work in many common places:

- Amusement Parks: They play a key role in operating safety mechanisms like gates, brakes, and restraint systems. Compressors also control animatronics, launch systems, and even power cleaners and washer systems.

- Automotive Sector: Beyond inflating tires, compressed air is essential in manufacturing vehicle parts—from seat fabrics to exhaust pipe sanding—and is integral to safety systems like air brakes, suspension, and airbags.

- Car Manufacturing & Service: Factories and workshops use compressed air for a variety of tasks, including painting, cleaning, dent repair, and precision spraying.

- DIY and Home Projects: Whether you’re into woodworking, metalworking, crafting, or gardening, compressed air tools—like nail guns, spray guns, and inflators—make projects easier and more efficient.

- Dry Cleaning: From pressing garments to operating steam cleaners and stain-removal tools, compressed air supports the cleaning process in professional settings.

Why Choose Compressed Air?

Industry professionals often refer to the air compressor as the “fourth utility”—following water, electricity, and gas—because of its critical role in both commercial and industrial applications.

- Safety: Unlike electrical systems, compressed air tools pose minimal risk of shocks or fire—making them ideal for wet or hazardous environments.

- Flexibility: Air systems are versatile and portable, perfect for remote or rugged environments like construction sites or mines. They offer variable speed and torque with lightweight, durable tools.

- Cost Efficiency: Although energy costs per unit can be higher than electricity, pneumatic tools tend to be simpler, cheaper, and longer-lasting—making them economical over time.

Industrial Applications: From Food to Aquaculture

air compressor has far-reaching industrial roles across many sectors, particularly when it comes to applications requiring fine air quality:

- Food & Beverage: Oil-free air compressors, Class 0 compressed air is used for packaging, bottling, cleaning, aeration, fermentation, and storage—ensuring zero contamination.

- Metal Fabrication: Compressed air powers blast furnaces, dust collection, cooling systems, and instrument operations in metal treatment processes.

- Chemical & Petrochemical: Applications include refining, fertilizer production, dehydrogenation processes, and more, facilitated by Atlas Copco’s turbo compressors.

- Pulp & Paper: Air is used to transport pulp, dry and cool paper, and treat wastewater, all while maintaining cleanliness.

- Cement: Compressed air aids in material transport, silo operations, combustion air, and cooling. Variable speed drives help optimize energy use.

- Pharmaceuticals: Class 0 compressors ensure contamination-free air in packaging, fermentation, valve control, and wastewater management.

- PET Bottling: Clean air is necessary for blow molding, valve control, cleaning, and automation during packaging.

- Marine & Aquaculture: Compressed air supports aeration, pneumatic conveying, bubble curtains, and handling of live or dead fish—particularly with compact, reliable blowers.

- CNG Stations: Air compressors are vital for converting gas pressures, enabling fast-fill CNG operations for vehicles.

- Railways: Air systems power everything from onboard controls to brakes in trams and locomotives—with options for oil-free and oil-lubricated compressors.

- Power Generation & Wastewater: In power plants, compressors support instrument air and fuel boosting. In water treatment, they drive aeration, filtration, and backwashing systems.

- Oil & Gas: Tailored compressor systems meet stringent API and ISO standards for this sector worldwide.

In Summary

Air compressors are essential to both everyday and industrial applications. From powering tools in your garage to ensuring product safety in cleanroom environments, compressed air is a versatile, efficient, and indispensable resource.

Related Products

-

Atlas Copco Air Compressor G-Series

Price range: $8,000.00 through $10,000.00 -

Atlas Copco Air Compressor GA11+ – 30 FF

Price range: $880.00 through $1,800.00 -

Atlas Copco Air Compressor GA110VSD

Price range: $6,800.00 through $10,000.00 -

Atlas Copco Air Compressor GA132

Price range: $6,800.00 through $10,000.00