A Case Study of Atlas Copco Stationary Air Compressors in the Mining Industry

Atlas Copco Stationary Air Compressors Support Hanwang Mining’s Transition from Open-Pit to Underground Operations.

Atlas Copco Stationary Air Compressors Support Hanwang Mining’s Transition from Open-Pit to Underground Operations.

Discover how No Sabe Fallar, a BIC subsidiary in Mexico, reduced energy consumption by 20% using Atlas Copco GA oil-injected screw compressors and advanced control systems.

Atlas Copco is a world-leading industrial group with a global presence in compressors, expanders and air treatment systems, construction and mining equipment, power tools, and assembly systems.

This article provides an in-depth analysis of the ten key components of rotary screw compressor, offering professional technical guidance for equipment operators and maintenance engineers.

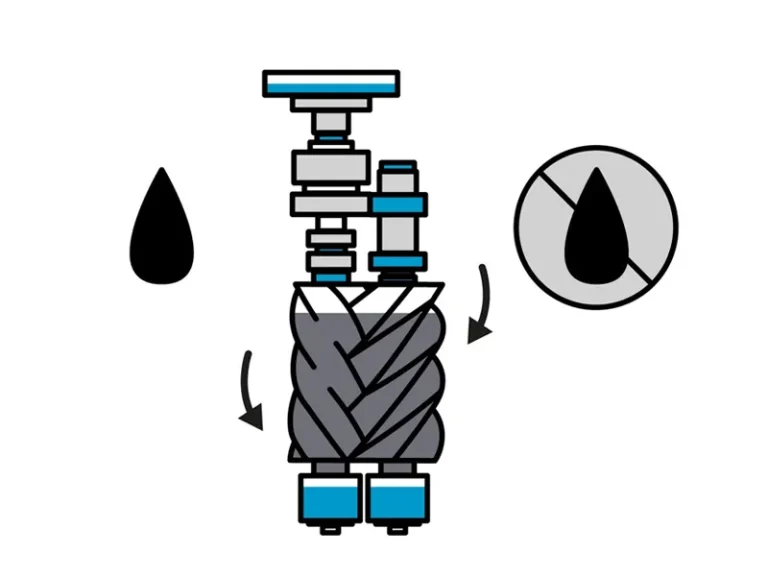

This article explores the key differences between oil-injected and oil-free rotary screw air compressors to help you make an informed decision for your business.

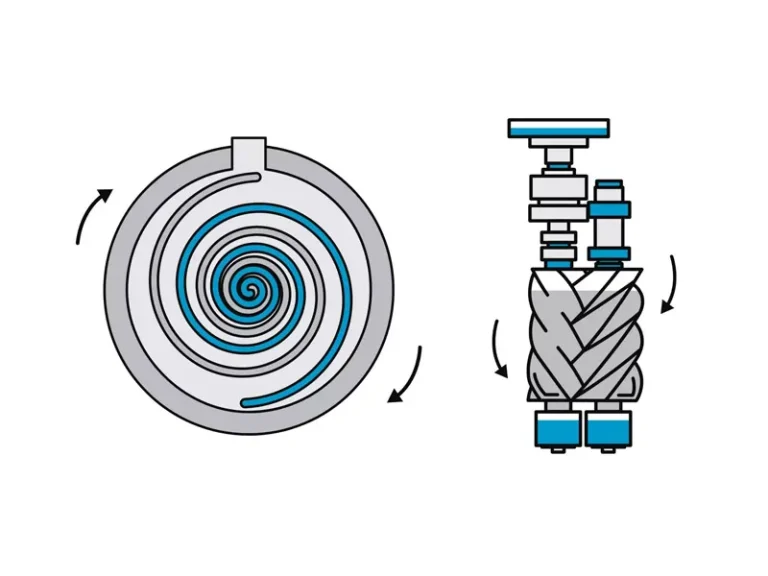

This article explores the key differences between scroll and screw compressors. We’ll also examine the…

Compressed air is widely used in various industrial and commercial sectors, serving as the power…

Atlas Copco launches the new GL160-250 low pressure oil injection screw air compressor, and GL160-250 VSD variable frequency air compressor is also on the market. The new product has a maximum flow rate of 55 cubic meters, completing the entire product line of the GL series.

The Atlas Copco GA132VSD is a reliable and high-performance air compressor, specifically designed for industrial applications that require continuous operation.