Oil-injected vs Oil-free Rotary Screw Air Compressors: What’s the Difference?

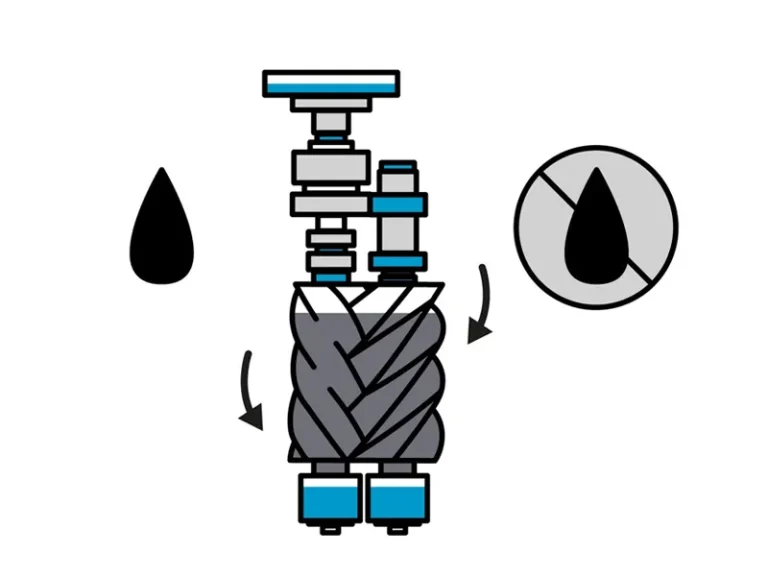

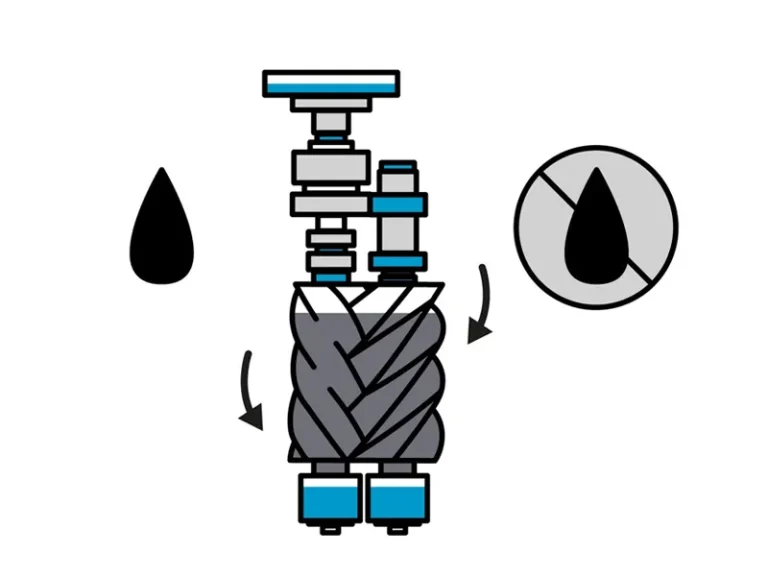

This article explores the key differences between oil-injected and oil-free rotary screw air compressors to help you make an informed decision for your business.

This article explores the key differences between oil-injected and oil-free rotary screw air compressors to help you make an informed decision for your business.

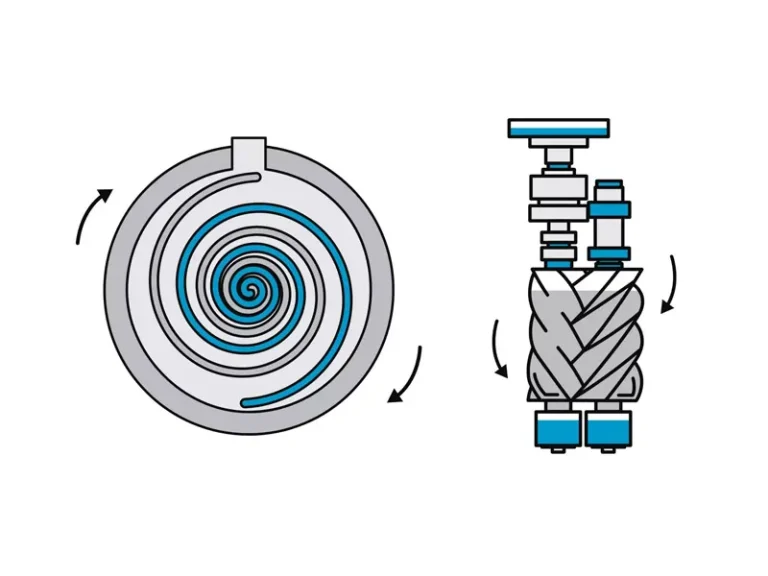

This article explores the key differences between scroll and screw compressors. We’ll also examine the…

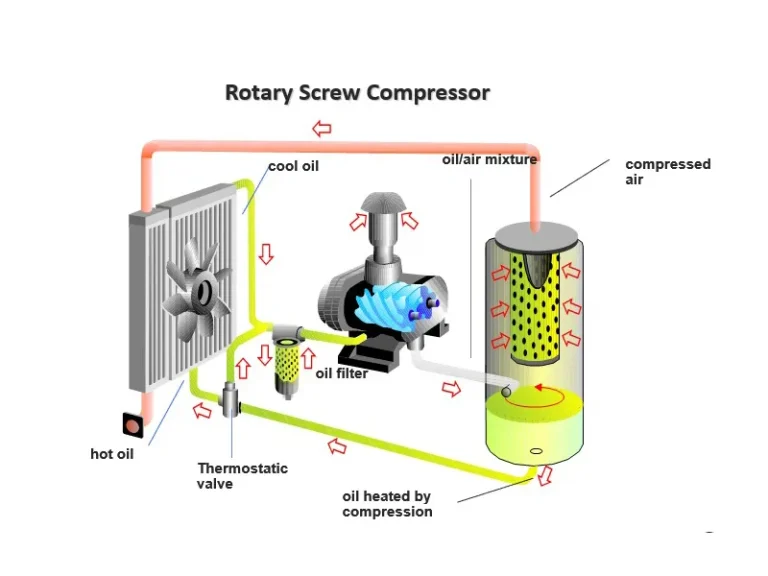

Rotary screw air compressors are widely used across industries due to their efficiency, reliability, and…

In modern industrial production, compressed air, as a crucial power source, is widely used across…

Compressed air is widely used in various industrial and commercial sectors, serving as the power…

Optimizing compressed air systems is crucial for reducing operational costs and ensuring continuous production. This article explores key strategies to enhance system efficiency and uptime, focusing on leak management, pressure optimization, maintenance planning, and air filtration.

This report will explore the diverse and crucial impacts of air filter cartridges on compressed air systems, examining their role in maintaining air quality, optimizing energy consumption, safeguarding downstream equipment, and the financial repercussions of neglecting proper filtration.

Seadweer, an officially authorized Atlas Copco air compressor supplier, continues to provide genuine Atlas Copco air compressors and parts worldwide without any disruption.

Atlas Copco launches the new GL160-250 low pressure oil injection screw air compressor, and GL160-250 VSD variable frequency air compressor is also on the market. The new product has a maximum flow rate of 55 cubic meters, completing the entire product line of the GL series.