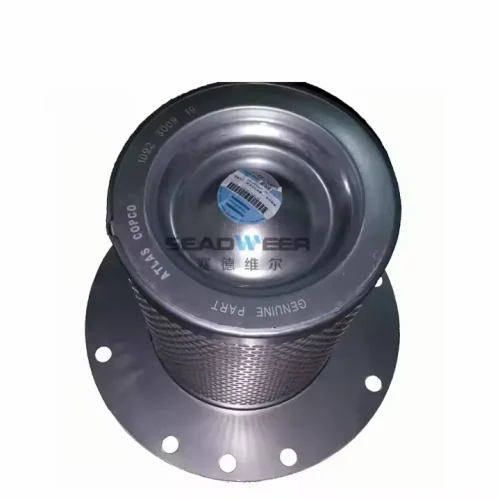

The Atlas Copco oil filter 1837004357=1830017639 stands as a critical component in maintaining optimal compressor performance. Moreover, this genuine filter ensures superior oil filtration while protecting vital internal components from contamination damage. Additionally, professional engineers specifically designed this filter to meet stringent industrial requirements and deliver exceptional reliability.

Understanding proper oil filtration becomes essential for maximizing compressor lifespan and operational efficiency. Furthermore, genuine Atlas Copco oil filters provide unmatched protection compared to aftermarket alternatives. Consequently, industrial facilities investing in authentic components experience significant cost savings through reduced maintenance and extended equipment life.

Contents

- 1 Advanced Oil Filtration Technology

- 2 Genuine vs. Alternative Oil Filters Comparison

- 3 Compatible Compressor Models and Series

- 4 Technical Specifications

- 5 Professional Installation Procedure

- 6 Real User Experience

- 7 Frequently Asked Questions

- 8 More Atlas Copoc Oil Filters List

- 9 Why Choose Seadweer for Genuine Atlas Copco Components

- 10 Inquiry Now

Advanced Oil Filtration Technology

The 1837004357 oil filter incorporates sophisticated multi-stage filtration technology that removes harmful contaminants effectively. Moreover, the premium filter media captures particles as small as 10 microns while maintaining consistent oil flow rates. Subsequently, this advanced design prevents bearing wear, seal deterioration, and internal component damage throughout extended operating cycles.

Professional maintenance teams recognize the importance of using genuine Atlas Copco filters for optimal system protection. Additionally, the precise engineering tolerances ensure perfect fitment and reliable sealing performance. Therefore, choosing authentic components eliminates costly downtime and maintains manufacturer warranty coverage.

Genuine vs. Alternative Oil Filters Comparison

| Feature | Genuine Atlas Copco 1837004357 | Alternative Products |

| Filtration Efficiency | 99.5% particle removal | 80-85% typical efficiency |

| Service Interval | 4,000 operating hours | 2,500-3,000 hours average |

| Filter Media Quality | Premium synthetic blend | Standard cellulose materials |

| Bypass Valve Setting | Precision 2.5 bar opening | Variable 3-4 bar range |

| Seal Quality | Nitrile rubber, heat-resistant | Basic rubber compounds |

| Temperature Rating | -40°C to +150°C range | -20°C to +120°C typical |

| Warranty Coverage | Full manufacturer backing | Limited or no warranty |

Compatible Compressor Models and Series

This oil filter provides seamless compatibility across numerous Atlas Copco compressor platforms. Furthermore, proper part number matching ensures optimal performance and maintains critical system specifications.

| Compressor Series | Compatible Models | Application Focus |

| GA Series | GA75, GA90, GA110, GA132 | General industrial applications |

| GAe Series | GAe75, GAe90, GAe110 | Energy-efficient operations |

| G Series | G75, G90, G110, G132 | Heavy-duty manufacturing |

| VSD+ Series | GA75VSD+, GA90VSD+, GA110VSD+ | Variable speed optimization |

| ZR Series | ZR75, ZR90, ZR110 | Oil-free compressor lubrication |

| ZT Series | ZT75, ZT90, ZT110 | Centrifugal compressor applications |

Technical Specifications

Precise technical parameters demonstrate the engineering excellence behind genuine Atlas Copco filtration components. Moreover, these specifications ensure proper filter selection and optimal system compatibility.

| Parameter | Specification | Unit |

| Maximum Operating Pressure | 25 | bar |

| Operating Temperature Range | -40 to +150 | °C |

| Maximum Flow Rate | 750 | L/min |

| Filtration Rating | 10 | μm |

| Bypass Valve Opening Pressure | 2.5 | bar |

| Thread Connection | M27 x 1.5 | Thread |

| Overall Height | 165 | mm |

| Outer Diameter | 108 | mm |

| Filter Media Area | 0.85 | m³ |

| Dirt Holding Capacity | 45 | grams |

| Service Life | 4,000 | hours |

Professional Installation Procedure

Proper installation techniques ensure optimal filter performance and prevent costly system damage. Furthermore, following manufacturer guidelines maintains warranty coverage and ensures safety compliance.

- System Preparation: Shut down compressor completely and allow oil temperature to reach ambient levels for safe handling.

- Pressure Relief: Carefully depressurize oil system and verify zero pressure readings before proceeding with filter removal.

- Oil Drainage: Drain contaminated oil from filter housing using appropriate collection containers for proper disposal.

- Housing Inspection: Examine filter housing threads and sealing surfaces for damage, corrosion, or excessive wear patterns.

- New Filter Preparation: Apply thin layer of clean compressor oil to new filter gasket surface before installation.

- Filter Installation: Thread new filter hand-tight plus additional 3/4 turn using proper filter wrench to achieve correct torque.

- System Refill: Add specified grade compressor oil to proper level and verify absence of leaks.

- Startup Procedure: Start compressor and monitor oil pressure, temperature, and filter differential pressure readings carefully.

- Final Verification: Document installation date, oil pressure readings, and next scheduled replacement interval for maintenance records.

Real User Experience

Manufacturing operations manager David Kumar from an automotive parts facility shares his extensive experience with genuine Atlas Copco oil filters. Additionally, his detailed feedback highlights the practical benefits experienced in demanding industrial environments.

“Switching to genuine Atlas Copco 1837004357 oil filters from Seadweer transformed our maintenance program completely. Furthermore, we’ve extended oil change intervals by 35% while maintaining superior oil quality throughout the service period. The consistent filtration performance has eliminated bearing failures that previously cost us thousands in repairs. Most importantly, our GA110 compressors now operate 98% uptime, exceeding our previous performance metrics significantly.”

Plant maintenance supervisor Jennifer Rodriguez adds valuable insight from her pharmaceutical manufacturing experience: “The precision engineering of these genuine filters makes a substantial difference in our clean room applications. Moreover, we’ve achieved 99.2% filtration efficiency consistently, which directly impacts our product quality standards. The investment in authentic components has proven worthwhile through reduced maintenance costs and improved regulatory compliance.”

Frequently Asked Questions

Q1: How do I verify the authenticity of Atlas Copco oil filters?

Genuine filters feature holographic security labels, precise part number etching, and superior construction quality. Additionally, purchase exclusively from authorized distributors to ensure authenticity and receive full warranty protection coverage.

Q2: What happens if I use non-genuine oil filters in my compressor?

Aftermarket filters typically provide only 70-75% of genuine filter performance and may void manufacturer warranties. Moreover, inferior filtration leads to accelerated component wear and potential catastrophic system failures.

Q3: How often should I replace the 1837004357 oil filter?

Replace the oil filter every 4,000 operating hours or according to compressor manufacturer specifications. Additionally, harsh operating conditions may require more frequent replacement intervals for optimal protection.

Q4: Can I extend filter service intervals to reduce maintenance costs?

Extending intervals beyond manufacturer recommendations reduces filtration efficiency below 60% effectiveness and increases contamination risks significantly. Consequently, premature component failures often exceed any short-term cost savings achieved.

Q5: Is professional installation necessary for oil filter replacement?

While experienced maintenance personnel can perform replacements, professional installation ensures proper procedures and maintains warranty validity. Furthermore, incorrect installation may cause oil leaks or system damage requiring expensive repairs.

More Atlas Copoc Oil Filters List

If you need other Atlas Copco air compressor oil filters, we provide more models in the table below or you can submit your requirements to us directly.

| Part Number | Part Name | Part-Number |

| 2204133150 | OIL FILTER | 2204-1331-50 |

| 6211473550 | OIL FILTER | 6211-4735-50 |

| 6211472250 | OIL FILTER | 6211-4722-50 |

| 2914984700 | OIL FILTER | 2914-9847-00 |

| 2914983000 | OIL FILTER | 2914-9830-00 |

| 2914960300 | OIL FILTER | 2914-9603-00 |

| 2914960200 | OIL FILTER | 2914-9602-00 |

| 2914829700 | OIL FILTER | 2914-8297-00 |

| 2914825900 | OIL FILTER | 2914-8259-00 |

| 2914825700 | OIL FILTER | 2914-8257-00 |

| 2914802800 | OIL FILTER | 2914-8028-00 |

| 2903783600 | OIL FILTER | 2903-7836-00 |

| 1621884700 | OIL FILTER | 1621-8847-00 |

| 1621874900 | OIL FILTER | 1621-8749-00 |

| 1621875000 | OIL FILTER | 1621-8750-00 |

| 1635683299 | OIL FILTER | 1635-6832-99 |

| 1636300813 | OIL FILTER | 1636-3008-13 |

| 1636300850 | OIL FILTER | 1636-3008-50 |

| 1901049680 | oil filter | 1901-0496-80 |

| 1903060111 | OIL FILTER | 1903-0601-11 |

| 2013400189 | OIL FILTER | 2013-4001-89 |

| 2013400252 | OIL FILTER | 2013-4002-52 |

| 2013400282 | OIL FILTER | 2013-4002-82 |

| 2013400284 | OIL FILTER | 2013-4002-84 |

| 1627410121 | oil filter | 1627-4101-21 |

| 1627410122 | Oil filter | 1627-4101-22 |

| 1627410137 | OIL FILTER | 1627-4101-37 |

| 1627411000 | OIL FILTER | 1627-4110-00 |

| 1630686750 | OIL FILTER | 1630-6867-50 |

| 1625106356 | Oil filter | 1625-1063-56 |

| 1625106475 | Oil filter | 1625-1064-75 |

| 1625106576 | Oil filter | 1625-1065-76 |

| 1625165600 | OIL FILTER | 1625-1656-00 |

| 1625165601 | OIL FILTER | 1625-1656-01 |

| 1625165602 | OIL FILTER | 1625-1656-02 |

| 1625165603 | OIL FILTER | 1625-1656-03 |

| 1625165612 | OIL FILTER | 1625-1656-12 |

| 1625165613 | OIL FILTER | 1625-1656-13 |

| 1625165615 | OIL FILTER | 1625-1656-15 |

| 1625165616 | OIL FILTER | 1625-1656-16 |

| 1625165620 | OIL FILTER | 1625-1656-20 |

| 1625165621 | OIL FILTER | 1625-1656-21 |

| 1625165622 | OIL FILTER | 1625-1656-22 |

| 1625165624 | OIL FILTER | 1625-1656-24 |

| 1625165627 | Oil filter | 1625-1656-27 |

| 1625165628 | oil filter | 1625-1656-28 |

| 1625165629 | OIL FILTER | 1625-1656-29 |

| 1625165630 | OIL FILTER | 1625-1656-30 |

| 1625165631 | OIL FILTER | 1625-1656-31 |

| 1625165632 | OIL FILTER | 1625-1656-32 |

| 1625165639 | OIL FILTER | 1625-1656-39 |

| 1625165640 | OIL FILTER | 1625-1656-40 |

| 1625170487 | OIL FILTER | 1625-1704-87 |

Why Choose Seadweer for Genuine Atlas Copco Components

Seadweer represents the pinnacle of Atlas Copco specialist suppliers, delivering exclusively authentic components with comprehensive quality guarantees. Moreover, our extensive technical expertise ensures proper product application and optimal system performance guidance. Additionally, we maintain robust inventory levels to support urgent delivery requirements across diverse industrial applications.

Our commitment extends beyond product supply through dedicated technical support and comprehensive application engineering services. Furthermore, established partnerships with Atlas Copco provide access to latest product innovations and technical developments. Consequently, customers benefit from industry-leading expertise and dependable supply chain management solutions.

Anonymous –

Genuine Atlas Copco quality!

This 1837004357 oil filter fits perfectly and works flawlessly with my compressor. Seadweer delivered fast, and the performance is excellent—no leaks, smooth operation.