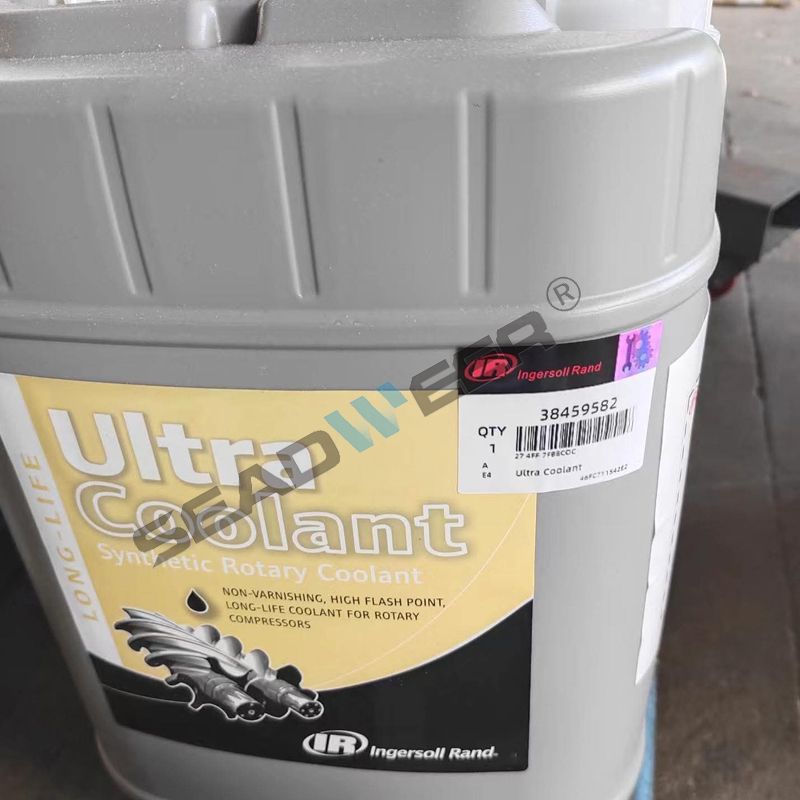

When it comes to maintaining optimal performance in rotary screw air compressors, choosing the right coolant makes all the difference. Furthermore, the Ingersoll Rand 38459582 Ultra Coolant Lubricant represents a breakthrough in compressor technology. This engineered polyglycol-based coolant delivers exceptional performance even under the most demanding conditions.

Modern industrial operations require reliable, efficient compressor systems. Additionally, they need lubricants that can withstand extreme temperatures while maintaining peak performance. The Ultra Coolant addresses these challenges head-on with its advanced formulation.

Contents

What Makes Ultra Coolant Special?

Ultra Coolant stands apart from conventional petroleum-based coolants through its innovative design. Moreover, this specialized lubricant offers superior thermal conductivity that significantly extends compressor life. The unique polyglycol formulation provides consistent performance across a wide temperature range.

Traditional coolants often fail under high-temperature conditions. However, Ultra Coolant maintains its properties even in the most challenging environments. This reliability translates directly into reduced downtime and lower maintenance costs for your operation.

The engineering behind Ultra Coolant focuses on three key areas: thermal management, component protection, and operational efficiency. Consequently, users experience improved performance across all these critical aspects.

Key Product Advantages

Extended Operating Life and Durability

Ultra Coolant delivers up to 8,000 hours of lubricant run time. Furthermore, this extended life cycle reduces replacement frequency and associated labor costs. The advanced formula lasts longer than most poly-alpha-olefins (PAOs). In fact, it provides up to 8 times the life of conventional lubricants.

This exceptional longevity results from the coolant’s resistance to thermal breakdown. Additionally, the stable molecular structure maintains lubricating properties throughout the extended service life. Operators benefit from fewer oil changes and reduced disposal costs.

Superior Thermal Performance

The coolant features 10% higher thermal conductivity compared to standard lubricants. Moreover, this enhanced heat transfer capability keeps compressors running cooler and more efficiently. The high flash point of 271°C (520°F) exceeds most synthetic alternatives.

This thermal superiority becomes especially important in high-ambient temperature environments. Furthermore, the improved heat dissipation prevents thermal stress on critical components. Compressors operate more reliably even during peak summer conditions.

Non-Foaming Excellence

Ultra Coolant’s non-foaming performance significantly reduces carryover compared to conventional fluids. Additionally, this characteristic minimizes contamination in downstream equipment. The stable foam characteristics maintain consistent lubrication under all operating conditions.

Reduced foaming also improves separator efficiency. Consequently, users experience cleaner compressed air output and extended separator life. This translates into lower maintenance requirements and improved air quality.

Environmental and Safety Benefits

The coolant offers excellent biodegradability and recyclability characteristics. Moreover, the environmentally conscious formulation reduces ecological impact without compromising performance. The high flash point enhances operational safety in industrial environments.

Varnish-free operation saves energy while extending system reliability. Furthermore, this clean-running characteristic reduces internal deposits that can impair efficiency. Operators benefit from improved energy efficiency and extended component life.

Product Comparison Table

| Feature | Ultra Coolant 38459582 | Standard PAO Lubricants | Conventional Petroleum |

| Service Life | Up to 8,000 hours | 3,000-4,000 hours | 1,000-2,000 hours |

| Flash Point | 271°C (520°F) | 220-240°C | 180-200°C |

| Thermal Conductivity | 10% higher than standard | Standard performance | Below standard |

| Foaming Characteristics | Non-foaming | Moderate foaming | High foaming tendency |

| Biodegradability | Excellent | Limited | Poor |

| Varnish Formation | Varnish-free | Low varnish | High varnish formation |

Technical Specifications

| Parameter | Specification | Test Method |

| Base Oil Type | Engineered Polyglycol | – |

| HS code | 34039919 | – |

| Viscosity @ 40°C | 46 cSt | ASTM D445 |

| Viscosity @ 100°C | 8.2 cSt | ASTM D445 |

| Viscosity Index | 140 | ASTM D2270 |

| Flash Point | 271°C (520°F) | ASTM D92 |

| Pour Point | -40°C (-40°F) | ASTM D97 |

| Thermal Conductivity | 10% above standard | ASTM C177 |

| Biodegradability | >60% in 28 days | OECD 301B |

Model Specifications

| Bottle Size | Part Number |

| 1 liter (0.3 gallons) | 92837095 |

| 5 liters (1.2 gallons) | 92692284 |

| 20 liters (5.28 gallons) | 38459582 |

| 208 liters (55 gallons) | 39433743 |

Installation Procedure

Installing Ultra Coolant requires careful attention to proper procedures. Follow these steps to ensure optimal performance:

Step 1: System Preparation

First, shut down the compressor and allow it to cool completely. Next, drain the existing lubricant completely from the system. Clean the oil reservoir and replace the oil filter element.

Step 2: Component Inspection

Inspect all seals, gaskets, and connections for wear or damage. Replace any compromised components before adding new coolant. Check the oil cooler for cleanliness and proper operation.

Step 3: Filling Process

Add Ultra Coolant slowly to prevent foaming during the initial fill. Fill to the recommended level as specified in your compressor manual. Typically, the 20-liter (5.28 gallon) container provides sufficient volume for most applications.

Step 4: System Startup

Start the compressor and run it at no load for 10-15 minutes. Monitor oil pressure and temperature during this initial run period. Check for any leaks around fittings and connections.

Step 5: Final Verification

After the initial run period, recheck the oil level and top off if necessary. Document the installation date and initial oil level for maintenance records. Schedule the first oil analysis at 500 hours of operation.

Real User Experience

John Martinez, Maintenance Manager at Pacific Coast Manufacturing, shares his experience with Ultra Coolant: “We switched to Ingersoll Rand Ultra Coolant six months ago across our entire compressor fleet. The results have been remarkable. Our maintenance intervals increased by 40%, and we’ve seen a 15% reduction in energy consumption.

“Previously, we were changing oil every 2,000 hours with conventional lubricants. Now, we’re confidently running 6,000+ hours between changes. The non-foaming characteristic eliminated our separator clogging issues completely. Our compressed air quality has improved significantly, which directly impacts our production quality.

“The installation was straightforward, and the technical support from Ingersoll Rand made the transition smooth. We’re planning to expand Ultra Coolant use to our backup compressors based on these excellent results. The cost savings alone justify the premium price point.”

Frequently Asked Questions

Q1: How often should I change Ultra Coolant?

Ultra Coolant provides up to 8,000 hours of service life under normal operating conditions. However, we recommend oil analysis at 4,000-hour intervals to optimize change intervals based on your specific operating conditions.

Q2: Can I mix Ultra Coolant with existing lubricants?

While Ultra Coolant is compatible with most synthetic lubricants, we recommend complete system drainage for optimal performance. Mixing different lubricant types may reduce the extended service life benefits.

Q3: What temperature range does Ultra Coolant handle?

Ultra Coolant operates effectively from -40°C to 200°C (-40°F to 392°F). The high flash point of 271°C provides an excellent safety margin for high-temperature applications.

Q4: Does Ultra Coolant work in older compressor models?

Yes, Ultra Coolant is compatible with most rotary screw compressors manufactured after 1990. However, consult your compressor manual or contact technical support for specific compatibility questions.

Q5: How does Ultra Coolant impact energy efficiency?

The 10% higher thermal conductivity and varnish-free operation typically result in 5-15% energy savings compared to conventional lubricants. Actual savings depend on operating conditions and compressor age.

Make the Smart Choice Today

Ultra Coolant represents the pinnacle of compressor lubricant technology. Moreover, its proven track record in demanding industrial applications speaks to its exceptional quality. The combination of extended service life, superior thermal performance, and environmental benefits makes it the clear choice for professionals.

Don’t let inferior lubricants compromise your compressor performance. Furthermore, the cost of downtime far exceeds the investment in premium lubricant technology. Ultra Coolant pays for itself through reduced maintenance, improved efficiency, and extended equipment life.

Order your Ingersoll Rand 38459582 Ultra Coolant today and experience the difference that professional-grade lubricant makes. Contact air compressor spare parts dealer — Seadweer or visit our online store to secure your supply. Your compressors deserve the best – give them Ultra Coolant and watch your operational efficiency soar.

John Martinez –

High quality lubricant!

We switched to Ingersoll Rand Ultra Coolant from Seadweer one months ago across our entire compressor fleet. The results have been remarkable. Our maintenance intervals increased by 40%, and we’ve seen a 15% reduction in energy consumption.

Previously, we were changing oil every 2,000 hours with conventional lubricants. Now, we’re confidently running 6,000+ hours between changes. The non-foaming characteristic eliminated our separator clogging issues completely. Our compressed air quality has improved significantly, which directly impacts our production quality

Anonymous –

excellent service!

We recently purchased Ingersoll Rand 38459582 Ultra Coolant from Seadweer Air Compressor Co., and it’s been fantastic. Our compressor runs noticeably cooler and smoother, and we’ve seen a real improvement in efficiency. Highly recommend both the product and Seadweer’s excellent service!