In the world of industrial air compression, the air end stands as the absolute heart of the screw compressor. It is the crucial component responsible for performing the actual compression process, directly transforming mechanical power into usable compressed air. For Atlas Copco air compressors, the Genuine C142 Air End, specifically identified by part number 1616869383, represents the pinnacle of engineering precision and performance. This vital component embodies decades of Atlas Copco’s expertise in rotary screw technology, designed to deliver optimal efficiency, reliability, and extended service life.

When your compressor’s existing air end shows signs of wear, reduced output, or requires replacement during a major overhaul, installing a genuine unit is not merely a maintenance task; it is an absolute necessity for safeguarding your investment, ensuring peak energy efficiency, and maintaining the consistent, high-quality compressed air production your operations demand.

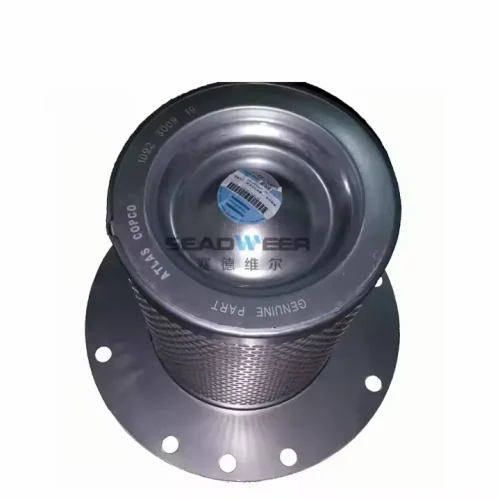

For businesses requiring this authentic, high-performance core component, Seadweer stands as a professional and trusted Atlas Copco supplier specializing in original air compressor parts. Consequently, choosing Seadweer ensures you acquire an air end manufactured to the exact specifications and uncompromising quality standards set by Atlas Copco.

Contents

- 1 Why the Air End is Paramount

- 2 Introducing the C142 Air End 1616869383

- 3 Key Advantages of the Genuine C142 Air End

- 4 Compatibility: Atlas Copco Compressors Using 1616869383 Air End

- 5 Installation Steps for Atlas Copco C142 Air End

- 6 Frequently Asked Questions (FAQs)

- 7 More Air End List

- 8 Conclusion

- 9 Inquiry Now

Why the Air End is Paramount

The air end of a screw compressor contains two precisely machined rotors—a male and a female—that intermesh. As these rotors turn, they draw in ambient air, trap it within their helical grooves, and continuously reduce its volume, thus compressing it. This mechanical process is incredibly demanding. The air end must operate at high rotational speeds, withstand significant internal pressures, and maintain extremely tight tolerances between the rotors and the housing. The efficiency of this compression process directly impacts your energy consumption, which typically accounts for a substantial 70% or more of a compressor’s total lifecycle cost.

Therefore, a worn or inefficient air end leads to tangible consequences: reduced compressed air output for the same power input, increased noise and vibration, higher operating temperatures, and ultimately, accelerated wear on other components, potentially resulting in catastrophic system failure. Maintaining a high-quality, efficient air end remains indispensable for minimizing operational costs and ensuring reliable air supply.

Introducing the C142 Air End 1616869383

The Genuine Atlas Copco C142 Air End, identified by part number 1616869383, is a sophisticated, precision-engineered compression element specifically designed for optimal performance within its designated Atlas Copco air compressor models. This specific part number signifies an air end meticulously crafted to achieve maximum volumetric and adiabatic efficiency. Atlas Copco manufactures this air end with unparalleled attention to detail, utilizing advanced rotor profiles that are precisely machined to microscopic tolerances. The robust housing, high-quality bearings (designed for high speeds and loads), and precision seals ensure a tight, efficient compression chamber and long operational life.

The design optimizes the interaction between the male and female rotors, which effectively minimizes internal leakage and reduces frictional losses. Each 1616869383 air end undergoes rigorous testing, which guarantees its compression efficiency, durability, noise levels, and overall performance characteristics. As an authentic component, this air end restores the compressor’s original performance, ensuring minimal energy consumption, quiet operation, and dependable compressed air output.

Key Advantages of the Genuine C142 Air End

Opting for the Genuine Atlas Copco C142 Air End 1616869383 delivers a range of significant advantages that directly impact your compressor’s long-term performance and profitability.

- Optimal Compression Efficiency: Its advanced rotor profile and precision machining ensure maximum air delivery for minimal power input. This results in significant energy savings over the compressor’s lifetime.

- Extended Service Life & Reliability: Manufactured from high-grade materials and incorporating robust bearings, the genuine air end offers an impressively long operational lifespan. This greatly reduces the frequency of costly major overhauls and associated downtime.

- Reduced Energy Consumption: The highly efficient design minimizes internal friction and air leakage within the compression chamber. This directly translates to lower electricity bills, a critical factor in operating costs.

- Minimized Noise & Vibration: Precision manufacturing and superior balancing properties contribute to exceptionally smooth rotation. This significantly reduces operational noise levels and minimizes vibration, improving the working environment.

- Precision-Engineered Rotor Profile: The specific C142 rotor profile is meticulously designed for a particular flow rate and pressure range. This ensures the air end operates at its peak efficiency within its intended application.

- Durable Materials & Robust Construction: Built with high-strength alloys and robust bearings, the air end withstands the intense pressures and continuous operation of industrial environments. This guarantees unwavering performance.

- Exact Compatibility & Seamless Integration: Designed and tested by Atlas Copco for specific compressor models, this air end ensures a perfect mechanical and performance fit. This preserves system integrity and maintains the compressor’s overall warranty.

Compatibility: Atlas Copco Compressors Using 1616869383 Air End

The Atlas Copco C142 Air End 1616869383 is a highly specific component designed for particular Atlas Copco air compressor models and series. Its precise dimensions, flow capabilities, and pressure ratings make it suitable only for its designated applications. This air end is typically found in various Atlas Copco GA and G series oil-injected screw compressors, where it serves as the primary compression element. The table below outlines representative Atlas Copco compressor series where this specific air end might be utilized. However, to guarantee compatibility for your exact compressor unit, it is absolutely essential to consult your machine’s technical documentation, specific part lists, or serial number, as air end requirements can vary even within the same series depending on the specific model variant, power rating, or manufacturing date.

| Compressor Series | Typical Models/Power Range (Representative) |

| GA Series | GA 37, GA 45, GA 55 (specific variants) |

| G Series | G 37, G 45, G 55 (specific variants) |

| Older GA/G models | Some legacy models may use this air end |

Note: This table provides representative examples; specific compatibility with the 1616869383 Air End part number must be verified based on your compressor’s full model, variant, and serial number, as specified in your documentation or by contacting a specialist.

Installation Steps for Atlas Copco C142 Air End

Installing a Genuine Atlas Copco C142 Air End 1616869383 is a highly complex, precision-demanding, and critical procedure. It requires specialized knowledge, specific tools, and significant experience with heavy machinery. Incorrect installation can lead to immediate and catastrophic failure of the air end, severe damage to the compressor, and pose serious safety risks. It is absolutely imperative that this procedure be performed only by highly qualified, certified Atlas Copco air compressor technicians or authorized service personnel.General Installation Steps (Requires Precision, Heavy Lifting & Expertise):

Critical Safety Protocols

Crucially, ensure the compressor is completely shut down, de-energized, and properly locked out/tagged out. Relieve all internal air pressure. Allow the entire compressor to cool completely. Drain all oil from the system. Secure the compressor against accidental movement.

Access and Disassembly

Safely remove all necessary panels, piping, electrical connections, and associated components to gain full access to the old air end. This often involves disconnecting oil lines, air lines, and the motor coupling. Be prepared for oil spillage.

Remove Old Air End

Using appropriate lifting equipment, carefully unbolt and lift the old air end from its mounting position. Exercise extreme caution, as air ends are very heavy.

Inspect and Clean Mounting Area:

Thoroughly clean the compressor frame or mounting base where the new air end will sit. Inspect for any damage, deformation, or debris. Ensure mounting surfaces are perfectly flat and clean.

Prepare New Air End

Unpack the new, Genuine Atlas Copco C142 Air End 1616869383 only when ready for installation. Inspect it for any visible transit damage. Ensure all new gaskets, O-rings, and mounting hardware are present and undamaged.

Position and Mount New Air End

Carefully lift the new air end using appropriate lifting points. Gently lower it onto the compressor frame, ensuring perfect alignment with mounting holes. Secure it using the specified bolts, tightening them to the precise torque values in the correct sequence as per the Atlas Copco manual.

Align with Motor and Coupling

Critically, precisely align the air end shaft with the motor shaft and install the coupling components. Proper alignment is absolutely crucial for preventing vibration, bearing wear, and premature coupling failure. Use specialized alignment tools (e.g., laser alignment kit).

Reconnect Systems

Reconnect all oil lines, air lines, and any associated sensors or electrical connections. Replace all necessary gaskets and O-rings with new ones. Ensure all connections are tight and leak-free.

Refill Oil and Pre-Checks

Refill the compressor with the correct type and quantity of genuine Atlas Copco compressor oil. Perform a thorough visual inspection for any loose connections, tools left inside, or signs of improper assembly.

Initial Start-up and Commissioning

Restore power to the compressor. Perform a controlled, supervised initial start-up according to Atlas Copco’s commissioning procedure. Closely monitor for any abnormal noises, vibrations, leaks, or overheating. Check all operating parameters (pressure, temperature, current draw) to ensure they are within specification. A thorough test run is essential before full production.

Disclaimer: This guide provides a simplified overview. Replacing an Atlas Copco air end is a major overhaul procedure. It requires highly specialized tools, extensive technical knowledge, experience with heavy machinery, and strict adherence to Atlas Copco’s detailed installation manuals and safety protocols. This work must only be performed by certified and authorized Atlas Copco service technicians. Attempting this without proper training will result in severe injury, catastrophic equipment damage, and will immediately void any existing warranties.

Frequently Asked Questions (FAQs)

Q1: What is the primary function of the C142 Air End 1616869383? A1: The C142 Air End is the core compression element of a screw compressor. It draws in ambient air and compresses it using rotating rotors, producing the usable compressed air.

Q2: Why is it vital to use a genuine Atlas Copco air end for replacement? A2: A genuine air end guarantees the original design, precise rotor profile, optimal clearances, and high-quality bearings. This ensures maximum energy efficiency, reduced noise, extended lifespan, and maintained compressor warranty.

Q3: How does a new air end improve compressor efficiency? A3: A new, genuine air end operates with optimal internal clearances and a precise rotor profile, which minimizes internal air leakage and frictional losses. This directly translates to more air produced per unit of power consumed, resulting in energy savings.

Q4: What are the signs that my compressor’s air end might need replacement? A4: Common signs include significantly reduced air output, increased noise or vibration, higher operating temperatures, excessive oil consumption, or the compressor tripping frequently on high temperature or overload alarms.

Q5: Is air end replacement a DIY task for a maintenance team? A5: Absolutely not. Air end replacement is a highly technical and complex procedure requiring specialized tools, heavy lifting equipment, precise alignment, and extensive training. It must only be performed by certified Atlas Copco service technicians.

More Air End List

If you need other Atlas Copco air compressor air end, we provide more models in the table below or you can submit your requirements to us directly.

| 1627456250 | AIREND KIT | 1627-4562-50 |

| 1627456256 | AIREND KIT | 1627-4562-56 |

| 1627456294 | AIREND KIT | 1627-4562-94 |

| 1627456897 | AIREND KIT | 1627-4568-97 |

| 1625164419 | AIREND PULLEY | 1625-1644-19 |

| 1625174075 | AIREND PULLEY | 1625-1740-75 |

| 2205721584 | INLET, AIREND, 1 1/2+ | 2205-7215-84 |

| 2205721734 | INLET, AIREND, 1 1/2+ | 2205-7217-34 |

| 2205721774 | INLET, AIREND, 2+ | 2205-7217-74 |

| 2205721893 | GASKET, AIREND OUTLET | 2205-7218-93 |

| 2205722005 | AIREND, FSS255112S | 2205-7220-05 |

| 2205722006 | AIREND, FSS255105C | 2205-7220-06 |

| 2205722011 | AIREND – MOTOR, PLETY | 2205-7220-11 |

| 2205722175 | AIREND, VMX 160RD | 2205-7221-75 |

| 2205722253 | COMPENSATOR, PIPE, AIREND SIDE | 2205-7222-53 |

| 2205722296 | AIREND, FSS321114C | 2205-7222-96 |

| 2205722298 | FLANGE, AIREND-MOTOR, D800 | 2205-7222-98 |

| 2205722334 | INLET, AIREND, 1 1/2+ | 2205-7223-34 |

| 2205722340 | AIREND, FSS255134S | 2205-7223-40 |

| 2205722349 | COMPENSATOR, AIREND SIDE | 2205-7223-49 |

| 2205722444 | AIREND, FSS255170S | 2205-7224-44 |

| 2205722748 | AIREND OUTLET 1-1/2 FORM 30-37 | 2205-7227-48 |

| 2205722749 | AIREND OUTLET 1-1/2 FORM 45 | 2205-7227-49 |

| 2205722811 | INLET, AIREND, 2+ | 2205-7228-11 |

| 2205827263 | REFURBISH KIT, AIREND, 204-123 | 2205-8272-63 |

| 2205829521 | AIREND, EVO9 | 2205-8295-21 |

| 2205829808 | REFURBISH KIT, AIREND, MM 3 | 2205-8298-08 |

| 2205829826 | SEALING KIT, AIREND, MM3. | 2205-8298-26 |

| 2989015800 | AIREND | 2989-0158-00 |

| 2989015700 | AIREND | 2989-0157-00 |

| 2989015401 | AIREND | 2989-0154-01 |

| 2989015400 | AIREND | 2989-0154-00 |

| 2989015200 | AIREND | 2989-0152-00 |

| 2989014500 | AIREND | 2989-0145-00 |

| 2989014400 | AIREND | 2989-0144-00 |

| 2989012200 | AIREND | 2989-0122-00 |

| 2989012100 | AIREND | 2989-0121-00 |

| 2989010400 | AIREND | 2989-0104-00 |

| 2989010300 | AIREND | 2989-0103-00 |

| 2989007600 | AIREND | 2989-0076-00 |

| 2989001900 | AIREND | 2989-0019-00 |

| 2989001200 | AIREND | 2989-0012-00 |

| 1616724890 | SERVICE STAGE AIREND C106 OMCO | 1616-7248-90 |

| 1616774590 | SERVICE AIREND C67 H10 | 1616-7745-90 |

| 1616774591 | SERVICE AIREND C67 H11 | 1616-7745-91 |

| 1616811890 | V111 AIREND | 1616-8118-90 |

| 1616813790 | AIREND | 1616-8137-90 |

| 1616820315 | AIREND, C55 PLUS | 1616-8203-15 |

| 1303002080 | AIREND, S111, 1303002080 | 1303-0020-80 |

| 1303002090 | SERVICE AIREND S111 K70 | 1303-0020-90 |

Conclusion

The Genuine Atlas Copco C142 Air End 1616869383 stands as the indispensable core of your air compressor, dictating its performance, efficiency, and longevity. Its precision engineering and advanced design ensure optimal air production and significant energy savings, safeguarding your entire operation. By choosing this authentic component from a professional supplier like Seadweer, you guarantee uncompromising quality and a seamless integration that restores your compressor to its peak operating condition. This action protects your investment and secures the uninterrupted, efficient performance your industrial processes rely upon. Trusting genuine parts for the very heart of your machine ultimately translates to superior operational value and complete peace of mind.

References:

1.Atlas Copco Official Website – Air Compressors: https://www.atlascopco.com/en-sg/compressors/products/air-compressors

2.Compressed Air & Gas Institute (CAGI) – Compressor Technology: https://www.cagi.org/

3.U.S. Department of Energy – Compressed Air Best Practices: https://www.energy.gov/eere/amo/compressed-air-best-practices

Anonymous_Buyer –

Truly impressed with its durability.

Replacing our old air end with the C142 (1616869383) has significantly boosted our Atlas Copco compressor’s efficiency. It’s running quieter and delivering consistent, high-quality compressed air. The performance improvement is remarkable, making this a worthwhile investment for continuous, reliable operation. Truly impressed with its durability.