The Atlas Copco GA 30⁺-90 | GA 37-90 VSD (30-90 kW/40-125 hp) series consists of oil-injected rotary screw air compressors, including fixed-speed models such as GA30⁺, GA37⁺, GA45⁺, GA55⁺, GA75⁺, and GA90, as well as variable speed drive (VSD) models like GA30VSD, GA37VSD, GA45VSD, GA55VSD, GA75VSD, and GA90VSD.

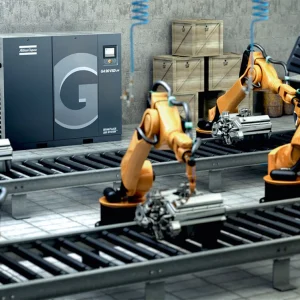

This series is recognized for its high efficiency, energy savings, and reliable performance, ensuring optimal operation under varying load demands. It has become a benchmark for industrial compressed air solutions. With advanced engineering, outstanding energy efficiency, and long-lasting durability, these compressors are widely used in industries such as manufacturing, food processing, and electronics production. They help customers significantly reduce energy costs while increasing productivity.Whether for traditional applications requiring stable output or complex working conditions demanding dynamic adjustment, the GA 30⁺-90 | GA 37-90 VSD series provides flexible and reliable compressed air support.

Contents

- 1 THE ULTIMATE SMART SOLUTION, DRIVEN BY EFFICIENCY

- 2 HIGH RELIABILITY AND SMART ENERGY GA 37⁺/45⁺/55⁺/75⁺ & GA 55/75/9

- 3 A STEP AHEAD IN MONITORING AND CONTROLS

- 4 VSD: DRIVING DOWN YOUR ENERGY COSTS

- 5 WHY DRY YOUR COMPRESSED AIR?

- 6 WORKPLACE: COMPRESSED AIR ATTHE POINT OF USE

- 7 Atlas Copco Air Compressors GA 30⁺-90|GA 37-90 VSD FLOWCHARTS

- 8 TECHNICAL SPECIFICATIONS

- 9 FAQ

- 10 Summary

- 11 Inquiry Now

THE ULTIMATE SMART SOLUTION, DRIVEN BY EFFICIENCY

Atlas Copco air compressors GA 30⁺-90 series bring you outstanding sustainability, reliability and performance, while minimizing the total cost of ownership. A choice of three premium compressor types (GA VSD, GA⁺ and GA) provides you with the compressed air solution that perfectly matches your requirements with clear value propositions. Built to perform even in the harshest environments, these compressors keep your production running efficiently.

GA PREMIUM COMPRESSOR

- High performanceFree Air Delivery.

- Premium quality at thelowest initial investment.

- Integrated refrigerant dryer.

- Standard Elektronikon® controller (optional graphic controller).

GA⁺ INDUSTRY-LEADING PERFORMANCE

- Industry-leading Free Air Delivery.

- Lowest energy consumption for applications with a stable air demand.

- Low noise emission suitable for workplace installation.

- Integrated refrigerant dryer.

- Smart Elektronikon® graphic compressor controller.

GA VSD ULTIMATE ENERGY SAVER

- On average up to 35% energy savings.

- Industry-leading operating turndown range.

- Wide pressure selection: 4-13 bar.

- Start under system pressure,no blow off.

- Integrated refrigerant dryer.

- In-house designed NEOS inverter.

- Smart Elektronikon® graphic compressor controller.

HIGH RELIABILITY AND SMART ENERGY GA 37⁺/45⁺/55⁺/75⁺ & GA 55/75/9

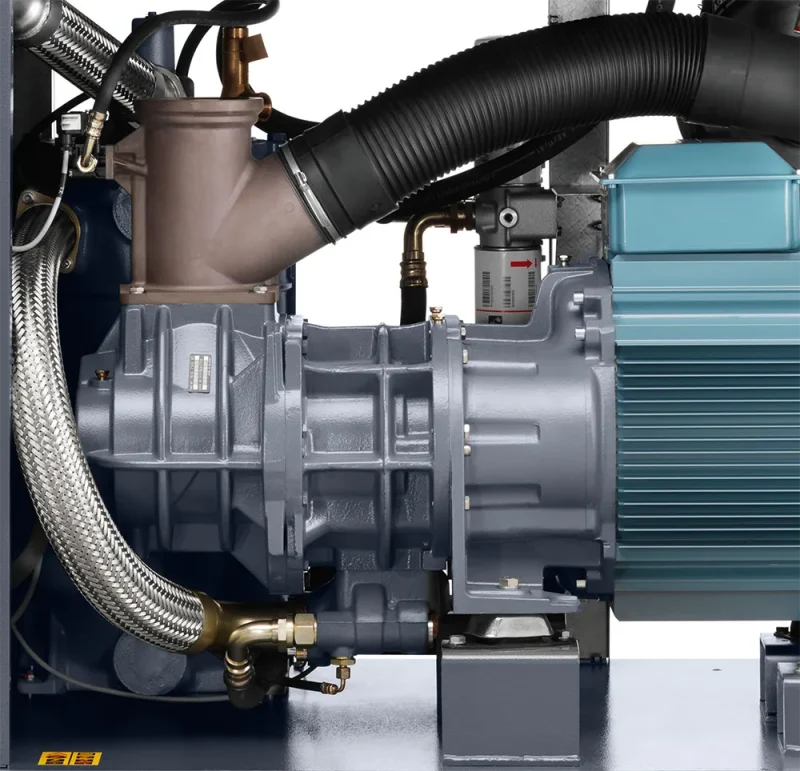

1.Maintenance-free drive system

- 100% maintenance-free; totally enclosed and protected against dirt and dust.

- Suitable for harsh environments.

- High-efficiency drive arrangement; no coupling or slippage losses.

- Standard up to 46˚C/115˚F and for high ambient version 55˚C/131˚F.

2.IE3 / NEMA Premium Efficiency electrical motors

- IP55,insulation Class F, B rise.

- Non-drive side bearing greased forlife.

- Designed for continuous operation in harsh environments.

3.Robust spin-on oil filter

- High-efficiency, removing 300% smaller particles than a conventional filter.

- Integrated bypass valve with the oil filter.

4.SIL Smart inlet lock system for GA VSD Atlas Copco air compressors

- Superior designed vacuum and air pressure controlled valve with minimal pressure drop and nosprings.

- Smart stop/start which eliminates back-pressure oil vapor

5.Separate oversized oil cooler and aftercooler

- Low element outlet temperatures, ensuring long oil lifetime.

- Removal ofnearly 100% condensate by integrated mechanical separator.

- No consumables.

- Eliminates possibility of thermal shocks in coolers

6.Electronic no-loss water drain

- Ensures constant removal of condensate.

- Manual integrated bypass for effective condensate removal in case of power failure.

- Integrated with compressor’s Elektronikon® with warning/alarm features.

7.Heavy-duty air intake filter

- Protects the compressor components by removing 99.9% of dirt particles down to 3 microns.

- Differential inlet pressure for proactive maintenance while minimizing pressure drop.

8.Elektronikon® for remote monitoring

- Integrated smart algorithms reduce system pressure and energy consumption.

- Monitoring features include warning indications, maintenance scheduling and online visualization of machine’s condition.

9.Cubicle cooling booster

- Cubicle in overpressure minimizes ingressof conductive dust.

- Electrical components remain cool, enhancing lifetime of components.

10.NEOS drive

- Atlas Copco’s in-house designed inverter for GA VSD compressors.

- IP5X protectiondegree.

- A robust, aluminum enclosure for trouble-free operation in the harshest conditions.

- Fewer components: compact, simple and user-friendly.

11.Integrated highly efficient R410A dryer

- Excellence inair quality.

- 50% reduction in energy consumption compared to traditional dryers.

- Zero ozone depletion.

- Incorporates optional UD⁺ filter according to Class 1.4.2.

A STEP AHEAD IN MONITORING AND CONTROLS

The next-generation Elektronikon® operating system offers a wide variety of control and monitoring features that allow you to increase your compressor’s efficiency and reliability. To maximize energy efficiency, the Elektronikon® controls the main drive motor and regulates system pressure within a predefined and narrow pressure band.

User-friendly

- 3.5-inch high-definition color display.

- Extra 4th LED indicator for service.

- Graphical display of key parameters (day, week, month) and 32 language settings.

- Graphical indication Serviceplan, remote control and connectivity functions.

Optional integrated compressor controller

Install,with a simple license, the optional integrated compressor controller and get simple, central control to reduce system pressure and energy consumption in installations of up to 4 (ES4i) or 6 (ES6i) compressors

SMARTLINK* Data Monitoring Program

• A remote monitoring system that helps you optimize your compressed air system and save you energy and cost.

• It offers you a complete insight in your compressed air network and anticipates on potential problems by warning you up-front.

* Please contact your local atlas copco air compressors supplier for more information.

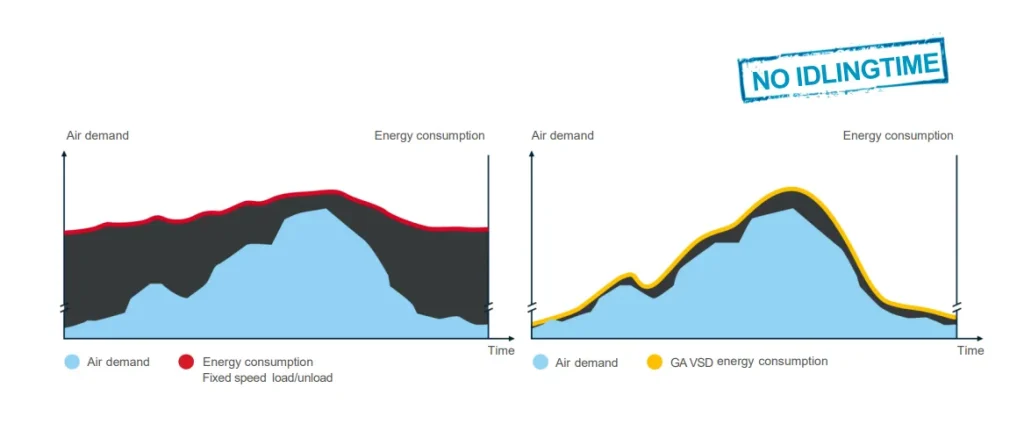

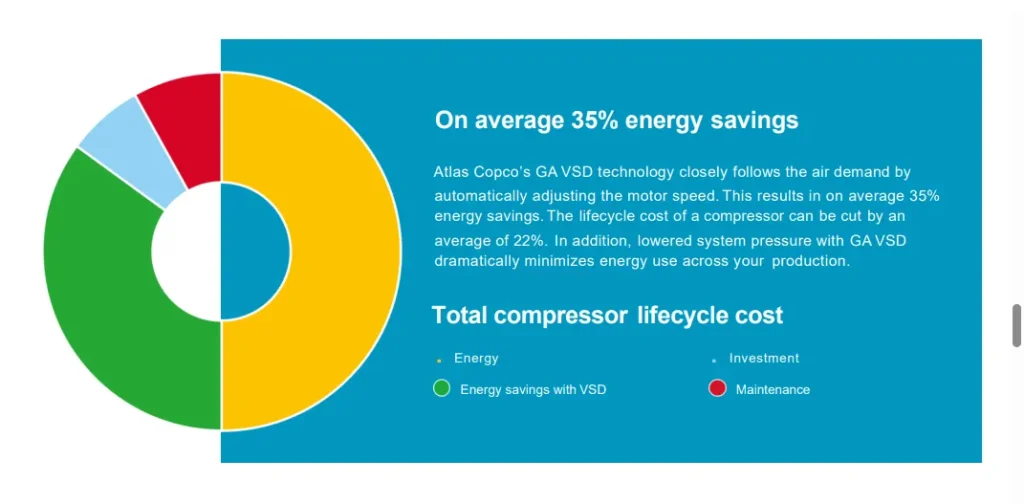

VSD: DRIVING DOWN YOUR ENERGY COSTS

Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. To cut your energy costs, Atlas Copco pioneered Variable Speed Drive (VSD) technology in the compressed air industry. VSD leads to major energy savings, while protecting the environment for future generations.Thanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD compressors on the market.

Why Atlas Copco Variable Speed Drive technology?

On average 35% energy savings during fluctuations in production demand with an extensive turndown range. Integrated Elektronikon Graphic controller controls the motor speed and high efficiency frequency inverter. No wasted idling times or blow-off losses in normal operation. Atlas Copco air compressors can start/stop under full system pressure without the need to unload with special VSD motor. Eliminates peak current penalty during start-up. Minimizes system leakage due to a lower system pressure. EMC Compliance to directives (2004/108/EG).

In almost every production environment, air demand fluctuates depending on different factors such as the time of the day, week or even month. Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand. Only 8% of all installations have a more stable air demand.

WHY DRY YOUR COMPRESSED AIR?

Untreated compressed air contains moisture, aerosols and dirt particles that can damage your air system and contaminate your end product, resulting in risk of corrosion and compressed air system leaks. Maintenance costs can far exceed air treatment costs. An air dryer is therefore essential to protect your systems and processes. The GA, GA+ and GA VSD Atlas Copco air compressors have an integrated dryer option to secure your peace of mind.

Integrated dry air

- Optimized sizing for the compressor, avoiding excessive energy consumption.

- Fit for your application.

- Controlled and monitored by theElektronikon® .

- Space-saving all-in-one solution with low installation costs.

Lowest lifecycle costs and peace of mind

- No extra installation costs.

- Saving floor space.

- Use of energy-efficient, environmentally friendly refrigerant R410A reduces operating costs and stands for zero ozone depletion.

- Heat exchanger cross-flow technology with low pressure drop, saving energy and costs.

- Zero waste of compressed air thanks tono-loss condensate drain.

- Advanced control functions ensure dry air under all circumstances and prevent freezing at low load.

- Pressure dew point of 3°C (100% relative humidity at 20°C).

Integrated purity

The optional UD⁺ filter and integrated refrigerant air dryer (IFD) efficiently remove moisture, aerosols and dirt particles to protect your investment. The UD⁺ filter has a 40% lower pressure drop than the conventional DD⁺/PD⁺ filter combination. It saves space and reduces energy costs. Using only 1 single filter it is possible to reach quality class 1.4.2 according to ISO 8573-1:2010.

| ISO quality class* | Dirt particle size | Water pressure dew point** | Oil concentration | |

| Pack compressor | 3.-.4 | 5 microns | – | 3 ppm |

| Integrated refrigerant dryer | 3.4.4 | 5 microns | +3°C/37°F | 3 ppm |

| DD⁺ | 2.4.2 | 1 micron | +3°C/37°F | 0.1 ppm |

| UD⁺ | 1.4.2 | 0.5 micron | +3°C/37°F | 0.1 ppm |

*The table values reflect the maximum limits according to the ISO quality air standard (ISO 8573-1:2010). ** Water pressure dew point based on 100% RH at 20°C/68°F.

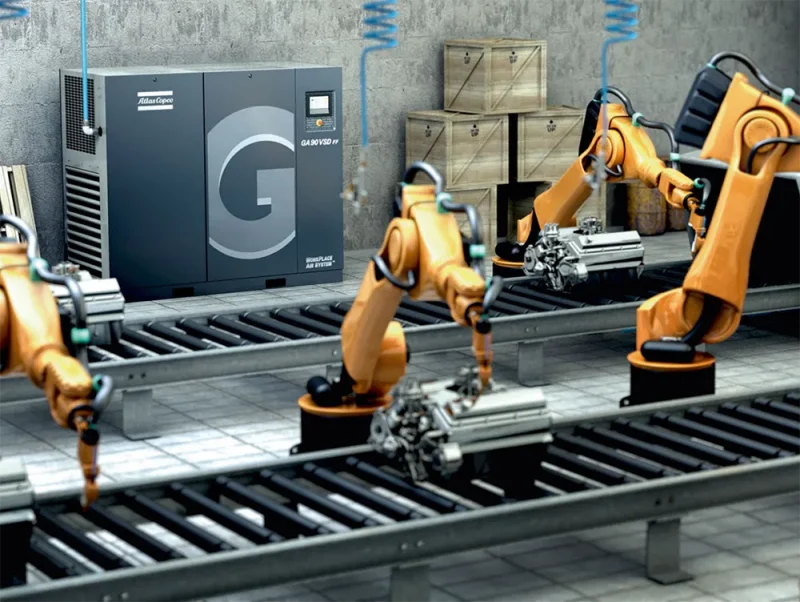

WORKPLACE: COMPRESSED AIR ATTHE POINT OF USE

With the industry-leading low noise operation and integration of air and condensate treatment equipment, the GA⁺ offers complete versatility for your production. The compressor’s integrated design allows it to be placed on the production floor, creating substantial energy savings foryour business.

Low installation costs

- The GA⁺ can operate close to the point of use – eliminating the need for a dedicated compressor room.

- The GA⁺ is delivered ready for use – minimizing production downtime and reducing installation costs.

- Filtration equipment is integrated – reducing the need for costly external piping and minimizing pressure drops. Low noise enables the above to be a reality.

Reduced energy and maintenance costs

- With less external piping, the GA⁺ minimizes pressure drop across the system which can reduce energy costs.

- The filtration system produces clean air to prevent network corrosion – minimizing energy, repair and maintenance costs.

- The GA⁺ operates at the lowest possible system pressure to reduce energy costs thanks to the Elektronikon® advanced monitoring system.

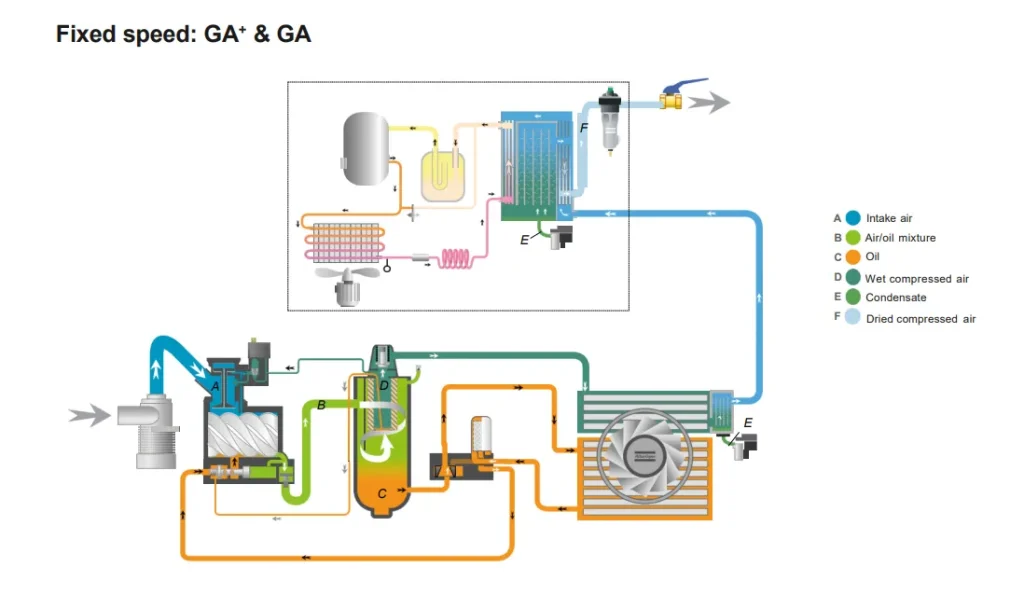

Atlas Copco Air Compressors GA 30⁺-90|GA 37-90 VSD FLOWCHARTS

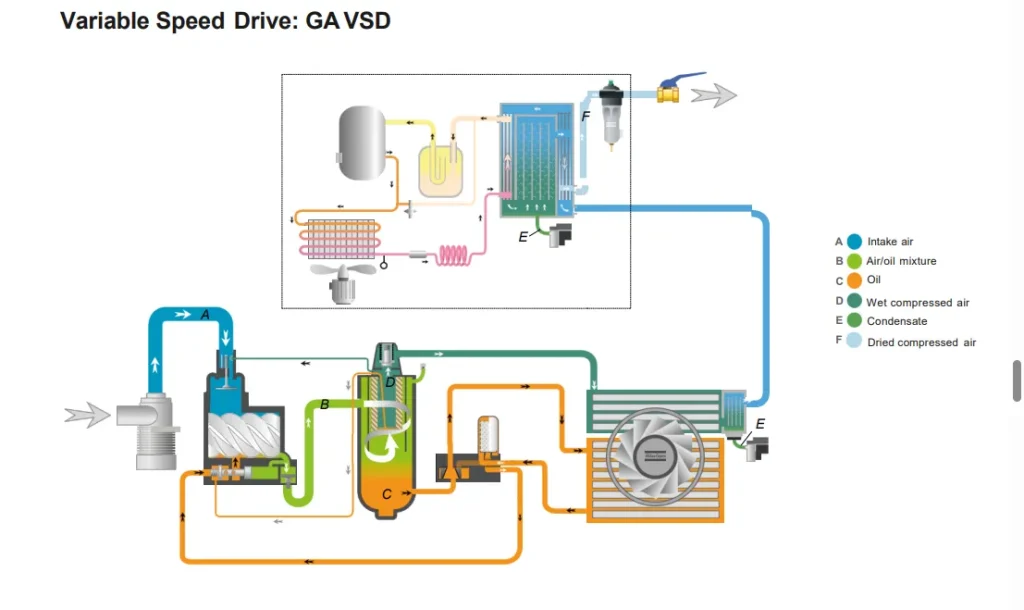

Variable Speed Drive: GA VSD

Fixed speed: GA⁺ & GA

TECHNICAL SPECIFICATIONS

GA 30⁺ -90 (50 HZ VERSIONS) Technical Specifications

| COMPRESSOR TYPE | Pressure variant | Max. working pressure WorkPlace |

Capacity FAD* | Installed motor power | Noise level | Weight WorkPlace | Weight WorkPlace Full Feature |

||||||

| bar(e) | psig | l/s | m³/hr | cfm | kW | hp | dB(A) | kg | lbs | kg | lbs | ||

| GA 30⁺ | 7.5 | 7.5 | 109 | 99 | 356 | 210 | 30 | 50 | 66 | 626 | 1380 | 796 | 1755 |

| 8.5 | 8.5 | 123 | 90 | 324 | 191 | 30 | 50 | 66 | 626 | 1380 | 796 | 1755 | |

| 10 | 10 | 145 | 83 | 299 | 176 | 30 | 50 | 66 | 626 | 1380 | 796 | 1755 | |

| 13 | 13 | 189 | 71 | 256 | 150 | 30 | 50 | 66 | 626 | 1380 | 796 | 1755 | |

| GA 37 | 7.5 | 7.5 | 109 | 116 | 418 | 246 | 37 | 60 | 67 | 683 | 1506 | 853 | 1881 |

| 8.5 | 8.5 | 123 | 108 | 389 | 229 | 37 | 60 | 67 | 683 | 1506 | 853 | 1881 | |

| 10 | 10 | 145 | 100 | 360 | 212 | 37 | 60 | 67 | 683 | 1506 | 853 | 1881 | |

| 13 | 13 | 189 | 88 | 317 | 186 | 37 | 60 | 67 | 683 | 1506 | 853 | 1881 | |

| GA 37⁺ | 7.5 | 7.5 | 109 | 121 | 436 | 256 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 |

| 8.5 | 8.5 | 123 | 114 | 410 | 242 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 | |

| 10 | 10 | 145 | 101 | 364 | 214 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 | |

| 13 | 13 | 189 | 85 | 306 | 180 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 | |

| GA 45 | 7.5 | 7.5 | 109 | 138 | 497 | 292 | 45 | 75 | 68 | 692 | 1526 | 900 | 1984 |

| 8.5 | 8.5 | 123 | 128 | 461 | 271 | 45 | 75 | 68 | 692 | 1526 | 900 | 1984 | |

| 10 | 10 | 145 | 120 | 432 | 254 | 45 | 75 | 68 | 692 | 1526 | 900 | 1984 | |

| 13 | 13 | 189 | 105 | 378 | 222 | 45 | 75 | 68 | 692 | 1526 | 900 | 1984 | |

| GA 45⁺ | 7.5 | 7.5 | 109 | 148 | 533 | 314 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 |

| 8.5 | 8.5 | 123 | 140 | 504 | 297 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 | |

| 10 | 10 | 145 | 127 | 457 | 269 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 | |

| 13 | 13 | 189 | 104 | 374 | 220 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 | |

| GA 55 | 7.5 | 7.5 | 109 | 173 | 623 | 367 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 |

| 8.5 | 8.5 | 123 | 162 | 583 | 343 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 | |

| 10 | 10 | 145 | 149 | 536 | 316 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 | |

| 13 | 13 | 189 | 129 | 464 | 273 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 | |

| GA 55⁺ | 7.5 | 7.5 | 109 | 184 | 662 | 390 | 55 | 75 | 66 | 1358 | 2994 | 1458 | 3214 |

| 8.5 | 8.5 | 123 | 174 | 626 | 369 | 55 | 75 | 66 | 1358 | 2994 | 1458 | 3214 | |

| 10 | 10 | 145 | 156 | 562 | 331 | 55 | 75 | 66 | 1358 | 2994 | 1458 | 3214 | |

| GA 75 | 7.5 | 7.5 | 109 | 224 | 806 | 475 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 |

| 8.5 | 8.5 | 123 | 212 | 763 | 449 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 | |

| 10 | 10 | 145 | 191 | 688 | 405 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 | |

| 13 | 13 | 189 | 170 | 612 | 360 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 | |

| GA 75⁺ | 7.5 | 7.5 | 109 | 249 | 896 | 528 | 75 | 100 | 68 | 1413 | 3115 | 1533 | 3380 |

| 8.5 | 8.5 | 123 | 236 | 850 | 500 | 75 | 100 | 68 | 1413 | 3115 | 1533 | 3380 | |

| 10 | 10 | 145 | 210 | 756 | 445 | 75 | 100 | 68 | 1413 | 3115 | 1533 | 3380 | |

| 13 | 13 | 189 | 179 | 644 | 379 | 75 | 100 | 68 | 1413 | 3115 | 1533 | 3380 | |

| GA 90 | 7.5 | 7.5 | 109 | 281 | 1012 | 595 | 90 | 125 | 73 | 1425 | 3142 | 1545 | 3406 |

| 8.5 | 8.5 | 123 | 275 | 990 | 583 | 90 | 125 | 73 | 1425 | 3142 | 1545 | 3406 | |

| 10 | 10 | 145 | 249 | 896 | 528 | 90 | 125 | 73 | 1425 | 3142 | 1545 | 3406 | |

| 13 | 13 | 189 | 217 | 781 | 460 | 90 | 125 | 73 | 1425 | 3142 | 1545 | 3406 | |

GA 30⁺ -90 (60 HZ VERSIONS) Technical Specifications

| COMPRESSOR TYPE | Pressure variant | Max. working pressure WorkPlace |

Capacity FAD* | Installed motor power | Noise level | Weight WorkPlace | Weight WorkPlace Full Feature |

||||||

| bar(e) | psig | l/s | m³/hr | cfm | kW | hp | dB(A) | kg | lbs | kg | lbs | ||

| GA 30⁺ | 100 | 7.4 | 107 | 101 | 364 | 214 | 30 | 40 | 66 | 643 | 1418 | 813 | 1795 |

| 125 | 9.1 | 132 | 92 | 331 | 195 | 30 | 40 | 66 | 643 | 1418 | 813 | 1792 | |

| 150 | 10.8 | 157 | 83 | 299 | 176 | 30 | 40 | 66 | 643 | 1418 | 813 | 1792 | |

| 175 | 12.5 | 181 | 75 | 270 | 159 | 30 | 40 | 66 | 643 | 1418 | 813 | 1792 | |

| GA 37 | 100 | 7.4 | 107 | 117 | 421 | 248 | 37 | 50 | 67 | 698 | 1539 | 868 | 1914 |

| 125 | 9.1 | 132 | 107 | 385 | 227 | 37 | 50 | 67 | 698 | 1539 | 868 | 1914 | |

| 150 | 10.8 | 157 | 98 | 353 | 208 | 37 | 50 | 67 | 698 | 1539 | 868 | 1914 | |

| 175 | 12.5 | 181 | 93 | 335 | 197 | 37 | 50 | 67 | 698 | 1539 | 868 | 1914 | |

| GA 37⁺ | 100 | 7.4 | 107 | 120 | 432 | 254 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 |

| 125 | 9.1 | 132 | 110 | 396 | 233 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 | |

| 150 | 10.8 | 157 | 100 | 360 | 212 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 | |

| 175 | 12.5 | 181 | 87 | 313 | 184 | 37 | 50 | 65 | 902 | 1989 | 987 | 2176 | |

| GA 45 | 100 | 7.4 | 107 | 139 | 500 | 295 | 45 | 60 | 68 | 745 | 1642 | 915 | 2017 |

| 125 | 9.1 | 132 | 130 | 468 | 275 | 45 | 60 | 68 | 745 | 1642 | 915 | 2017 | |

| 150 | 10.8 | 157 | 118 | 425 | 250 | 45 | 60 | 68 | 745 | 1642 | 915 | 2017 | |

| 175 | 12.5 | 181 | 108 | 389 | 229 | 45 | 60 | 68 | 745 | 1642 | 915 | 2017 | |

| GA 45⁺ | 100 | 7.4 | 107 | 147 | 529 | 311 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 |

| 125 | 9.1 | 132 | 134 | 482 | 284 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 | |

| 150 | 10.8 | 157 | 126 | 454 | 267 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 | |

| 175 | 12.5 | 181 | 110 | 396 | 233 | 45 | 60 | 66 | 970 | 2138 | 1060 | 2337 | |

| GA 55 | 100 | 7.4 | 107 | 175 | 630 | 371 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 |

| 125 | 9.1 | 132 | 157 | 565 | 333 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 | |

| 150 | 10.8 | 157 | 143 | 515 | 303 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 | |

| 175 | 12.5 | 181 | 131 | 472 | 278 | 55 | 75 | 69 | 1229 | 2709 | 1329 | 2930 | |

| GA 55⁺ | 100 | 7.4 | 107 | 185 | 666 | 392 | 55 | 75 | 67 | 1358 | 2994 | 1458 | 3214 |

| 125 | 9.1 | 132 | 167 | 601 | 354 | 55 | 75 | 67 | 1358 | 2994 | 1458 | 3214 | |

| 150 | 10.8 | 157 | 141 | 508 | 299 | 55 | 75 | 67 | 1358 | 2994 | 1458 | 3214 | |

| GA 75 | 100 | 7.4 | 107 | 227 | 817 | 481 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 |

| 125 | 9.1 | 132 | 202 | 727 | 428 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 | |

| 150 | 10.8 | 157 | 194 | 698 | 411 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 | |

| 175 | 12.5 | 181 | 175 | 630 | 371 | 75 | 100 | 73 | 1259 | 2776 | 1379 | 3040 | |

| GA 75⁺ | 100 | 7.4 | 107 | 250 | 900 | 530 | 75 | 100 | 69 | 1413 | 3115 | 1533 | 3380 |

| 125 | 9.1 | 132 | 227 | 817 | 481 | 75 | 100 | 69 | 1413 | 3115 | 1533 | 3380 | |

| 150 | 10.8 | 157 | 205 | 738 | 434 | 75 | 100 | 69 | 1413 | 3115 | 1533 | 3380 | |

| 175 | 12.5 | 181 | 182 | 655 | 386 | 75 | 100 | 69 | 1413 | 3115 | 1533 | 3380 | |

| GA 90 | 100 | 7.4 | 107 | 291 | 1048 | 617 | 90 | 125 | 74 | 1425 | 3142 | 1545 | 3406 |

| 125 | 9.1 | 132 | 267 | 961 | 566 | 90 | 125 | 74 | 1425 | 3142 | 1545 | 3406 | |

| 150 | 10.8 | 157 | 250 | 900 | 530 | 90 | 125 | 74 | 1425 | 3142 | 1545 | 3406 | |

| 175 | 12.5 | 181 | 228 | 821 | 483 | 90 | 125 | 74 | 1425 | 3142 | 1545 | 3406 | |

GA 37-90 VSD (50/60 HZ VERSIONS) Technical Specifications

| COMPRESSOR TYPE | Working pressure | Capacity FAD* | Installed motor power | Noise level | Weight WorkPlace |

Weight WorkPlace Full Feature | |||||||||

| bar(e) | psig | l/s | m³/hr | cfm | |||||||||||

| min | max | min | max | min | max | kW | hp | dB(A) | KG | LBS | KG | LBS | |||

| GA 37 VSD | 4 | 58 | 26 | 124 | 94 | 446 | 55 | 263 | 37 | 50 | 66/67 | 1042 | 2297 | 1127 | 2485 |

| 7 | 102 | 26 | 123 | 94 | 443 | 55 | 261 | 37 | 50 | 66/67 | 1042 | 2297 | 1127 | 2485 | |

| 10 | 145 | 25.8 | 107 | 93 | 385 | 55 | 227 | 37 | 50 | 66/67 | 1042 | 2297 | 1127 | 2485 | |

| 13 | 189 | 40.3 | 87 | 145 | 313 | 85 | 184 | 37 | 50 | 66/67 | 1042 | 2297 | 1127 | 2485 | |

| GA 45 VSD | 4 | 58 | 26 | 146 | 94 | 526 | 55 | 309 | 45 | 60 | 69/72 | 1100 | 2425 | 1190 | 2624 |

| 7 | 102 | 26 | 145 | 94 | 522 | 55 | 307 | 45 | 60 | 69/72 | 1100 | 2425 | 1190 | 2624 | |

| 10 | 145 | 25.8 | 128 | 93 | 461 | 55 | 271 | 45 | 60 | 69/72 | 1100 | 2425 | 1190 | 2624 | |

| 13 | 189 | 40.3 | 107 | 145 | 385 | 85 | 227 | 45 | 60 | 69/72 | 1100 | 2425 | 1190 | 2624 | |

| GA 55 VSD | 4 | 58 | 26 | 177 | 94 | 637 | 55 | 375 | 55 | 75 | 69/72 | 1380 | 3042 | 1480 | 3263 |

| 7 | 102 | 26 | 175 | 94 | 630 | 55 | 371 | 55 | 75 | 69/72 | 1380 | 3042 | 1480 | 3263 | |

| 10 | 145 | 25.4 | 155 | 91 | 558 | 54 | 328 | 55 | 75 | 69/72 | 1380 | 3042 | 1480 | 3263 | |

| 13 | 189 | 37 | 129 | 133 | 464 | 78 | 273 | 55 | 75 | 69/72 | 1380 | 3042 | 1480 | 3263 | |

| GA 75 VSD | 4 | 58 | 39,2 | 253 | 141 | 911 | 83 | 536 | 75 | 100 | 69/70 | 1534 | 3382 | 1654 | 3646 |

| 7 | 102 | 37,5 | 251 | 135 | 904 | 79 | 532 | 75 | 100 | 69/70 | 1534 | 3382 | 1654 | 3646 | |

| 10 | 145 | 48.1 | 219 | 173 | 788 | 102 | 464 | 75 | 100 | 69/70 | 1534 | 3382 | 1654 | 3646 | |

| 13 | 189 | 58.3 | 182 | 210 | 655 | 124 | 386 | 75 | 100 | 69/70 | 1534 | 3382 | 1654 | 3646 | |

| GA 90 VSD | 4 | 58 | 41,2 | 295 | 148 | 1062 | 87 | 625 | 90 | 125 | 73/74 | 1534 | 3382 | 1654 | 3646 |

| 7 | 102 | 39.4 | 293 | 142 | 1055 | 83 | 621 | 90 | 125 | 73/74 | 1534 | 3382 | 1654 | 3646 | |

| 10 | 145 | 48.3 | 257 | 174 | 925 | 102 | 545 | 90 | 125 | 73/74 | 1534 | 3382 | 1654 | 3646 | |

| 13 | 189 | 59.4 | 214 | 214 | 770 | 126 | 453 | 90 | 125 | 73/74 | 1534 | 3382 | 1654 | 3646 | |

FAQ

Here are five frequently asked questions (FAQs) based on the Atlas Copco GA 30⁺-90 GA 37-90 VSD Air Compressors:

1. What is the main difference between the GA 30⁺-90 and GA 37-90 VSD series air compressors?

The GA 30⁺-90 series are fixed-speed air compressors, ideal for applications with stable air demand. In contrast, the GA 37-90 VSD series features Variable Speed Drive (VSD) technology, which automatically adjusts motor speed based on actual air demand. This makes it more suitable for applications with fluctuating loads, helping to save energy and reduce operational costs.

2. How can I ensure the efficient operation of my air compressor?

Regular maintenance is key to ensuring optimal performance. This includes periodically checking and replacing air filters, oil filters, and lubricant oil, keeping the cooling system clean, and inspecting all electrical and mechanical connections. Following the manufacturer’s maintenance schedule will help extend the lifespan of your equipment and maintain its efficiency.

3. What could cause a high-temperature alarm during air compressor operation?

A high-temperature alarm can be triggered by various factors, including excessive ambient temperature, a clogged cooler, low oil levels, a blocked oil filter, or a malfunctioning cooling fan. It is recommended to check environmental conditions, ensure the cooling system is clean, maintain proper oil levels, and inspect the related components for potential issues.

4. How do I address excessive oil consumption in my air compressor?

Excessive oil consumption may be caused by an overfilled oil level, a clogged oil return pipe, a damaged oil separator filter, or the use of incorrect lubricating oil. To resolve this, check and adjust the oil level, clean or replace the oil return pipe and oil separator filter, and ensure you are using the manufacturer-recommended lubricant.

5. What factors should I consider when purchasing a GA 30⁺-90 or GA 37-90 VSD air compressor?

When purchasing an air compressor, consider the following factors:

-

Air demand: Ensure the compressor’s capacity matches your facility’s air consumption needs.

-

Energy efficiency: VSD models provide better energy savings for varying load demands.

-

Maintenance requirements: Choose a model with an accessible design for easy servicing.

-

Installation space: Ensure there is enough room for ventilation and maintenance.

-

Total cost of ownership: Consider initial costs, energy consumption, and maintenance expenses over time.

Summary

The Atlas Copco GA 30⁺-90 | GA 37-90 VSD series delivers outstanding energy efficiency, reliable operation, and flexible configurations, making it a trusted compressed air solution for industrial applications. Whether your goal is to reduce energy costs or enhance productivity, this series is designed to meet diverse demands and support your sustainable operations.

【Contact Us for a Tailored Solution】

Looking for high-performance Atlas Copco air compressors? The Atlas Copco GA series is your ideal choice! Reach out to our experts today for product details, customized solutions, or a free technical consultation. 📞 Call [+86 13244961963] or 📧 Email [seadweer@gmail.com]—let us optimize your compressed air system!

Download the Atlas Copco GA 30⁺-90|GA 37-90 VSD Air Compressors product brochure:Atlas Copco GA 30⁺-90 GA 37-90 VSD Air Compressors_Brochure_2935089249

Anonymous_Buyer –

We highly recommend the GA 37 VSD FF to anyone!

From the moment it was installed the Atlas Copco GA 37 VSD FF air compressor which purchased from seadweer, we noticed a significant improvement in our air supply – consistent pressure, no more lag, and it handles our demanding pneumatic tools with ease. What’s particularly impressive is its energy efficiency; our electricity bills have noticeably decreased compared to our previous unit. The GA 37 VSD FF runs much quieter too, creating a more comfortable working environment for our team. Maintenance has been surprisingly straightforward, with easy access to service points. Atlas Copco has always been a trusted name, but the GA 37 VSD FF has truly exceeded our expectations. It’s a robust, reliable workhorse that we can depend on day in and day out, making it a fantastic investment for our business. We highly recommend the GA 37 VSD FF to anyone looking for a high-performance, energy-efficient air compressor solution.