The Atlas Copco GA 180-315 VSD+ air compressors include GA 180, GA 200, GA 250, GA 315, GA 200 VSD+, GA 250 VSD+, and GA 315 VSD+. This series consists of highly efficient and reliable oil-lubricated screw compressors. Designed with innovative in-house technology, these GA series oil-injected compressors embody years of experience in developing premium solutions, ensuring exceptional performance and stability.

The shortest route to maximize your profitability is to minimize your operational costs. With up to 80% of a compressor lifecycle cost coming from the energy it consumes, this should be a clear focus. Atlas Copco’s GA 180-315 VSD+ compressors with Smart Injection enabled compression elements and IE4 or better class motors are designed to achieve significant energy savings while providing long and trouble-free life even in the harshest environmental conditions.

Contents

- 1 GA 180-315 VSD+ Efficiency

- 2 GA 180-315 VSD+ Serviceability

- 3 GA 180-315 VSD+ Flowchart

- 4 GA 180-315 VSD+ Technical specifications

- 5 Atlas Copco GA 180-315 VSD+ FAQ

- 5.1 1. What applications is the GA 180-315 VSD+ series air compressor suitable for?

- 5.2 2. What energy-saving technologies are used in the GA 180-315 VSD+ series?

- 5.3 3. What is the maintenance schedule and servicing requirement for this series?

- 5.4 4. Does the GA 180-315 VSD+ series support remote monitoring?

- 5.5 5. Is an integrated dryer option available?

- 6 Inquiry Now

GA 180-315 VSD+ Efficiency

At the heart of the GA compressors are state-of-the-art compression elements with SmartInjection technology and high efficiency oil cooled IE4 or better class motors. This highly efficient drive train coupled with generous cooling capacity, low internal pressure drops and precise control from the Elektronikon® Touch ensures optimum efficiency.

Variable Speed Drive (VSD)

Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. To cut your energy costs, Atlas Copco pioneered Variable Speed Drive(VSD) technology in the compressed air industry. VSD leads to major energy savings, while protecting the environment for future generations. Thanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD compressors on the market.

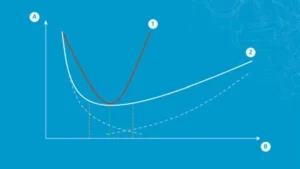

Legend

A = Losses B = Speed

1 = Total losses traditional element 2 = Total losses AC element

VSD savings

Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35%. The Life Cycle Cost of a compressor can be cut by an average of 22%. In addition, lowered system pressure with VSD minimizes energy use across your production dramatically.

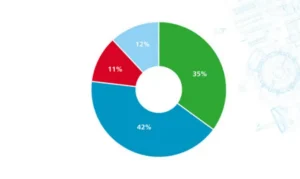

Legend

42% = Energy

35% = Energy savings with VSD 12% = Investment

11% = Maintenance

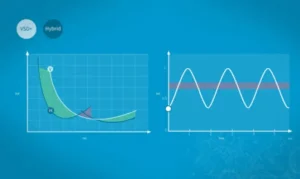

Dual set-point and automatic stop

Most production processes create fluctuating levels of demand which, in turn,can create energy waste in low use periods. Using the Elektronikon® unit controller, you can manually or automatically switch between two different setpoints to optimize energy use and reduce costs at low use times. In addition, the sophisticated algorithm runs the drive motor only when needed. As the desired setpoint is maintained while the drive motor’s runtime is minimized, energy consumption is kept to a minimum.

Legend

A = Power consumption B = Time

C = Energy Saving

Components designed for efficiency

- SmartInjection provides exact amount of oil required to element ensuring it always works at peak efficiency.

- High efficiency IE4 (Fixed Speed) and IE5 (VSD+) motor.

- Integrated energy recovery system recovers up to 78% of energy from integrated motor and element oil circuit.

- Dual speed or VSDfan for energy efficiency in lower temperatures.

Elektronikon Mk5 touch

The Elektronikon ® unit controller is specially designed to maximize the performance of your compressors and air treatment equipment under a variety of conditions. Our solutions provide you with key benefits such as increased energy efficiency, lower energy consumption, reduced maintenance times and less stress … less stress for both you and your entire air system.

SMARTLINK

Monitor your compressed air installation with SMARTLINK

Knowing the status of your compressed air equipment at all times is the surest way to achieve optimal efficiency and maximum availability.

Go for energy efficiency

Customized reports on the energy efficiency of your compressor room.

Increase uptime

All components are replaced on time, ensuring maximum uptime.

Save money

Early warnings avoid breakdowns and production loss.

Optimizer 4.0

Minimizing Excess Pressure

Optimizer 4.0 minimizes the generation of excess compressed air by starting and stopping compressors. Its user friendly interface enables you to set multiple pressure bands, allowing you to optimize your compressor installation for varying circumstances, such as non-productive hours.

Full VSD Benefits

With Optimizer 4.0 you can realize the full energy saving potential of VSD (Variable Speed Drive). It regulates the VSD to ensure that the compressed air output is proportional to the demand, preventing higher pressures than required, excess unloaded running, and spiraling energy costs.

Improving Uptime

Optimizer 4.0 effectively eliminates production downtime caused by unexpected system pressure drops, because it regulates the system pressure instead of the compressor output pressure.This means Optimizer 4.0 will automatically adjust the system pressure to compensate for pressure drops due to filters, piping and dryers for example.We also provide additional functionality and services on Optimizer 4.0 to ensure that your energy savings will stand the test of time.Even when your installation needs adaptations or your demand changes.

The Hybrid Concept

Our new VSDΔ combines the best of two technologies, namely the VSD and fixed speed drives. To match the customer’scompressed air demand our smart control system will regulate the combination to minimize the losses and enhance the efficiency even further than a VSD for certain load profiles. Profiles such as day/night or week/weekend are the ideal profiles to benefit from this innovation.

Hybrid Benefits

- Our hybrid compressor includes two drive trains. One variable speed and a fixed speed drive. This brings many benefits such as:

- Smaller footprint compared to having two smaller units

- Higher turndown compared to a VSD compressor

- Lower energy consumption

- Independent Single Core Operation

Higher Flexibilty

By having two cores and controllers, the customer can chose to run a single core if required, or if one core is not operational. This alsomeans the backup compressor can be sized smaller.

GA 180-315 VSD+ Serviceability

Service time is reduced to a minimum with all service parts grouped together for ease of access and, if greater access is required, the patented portal design enables full access to all components. Each component has also been designed for serviceability, halving the time required to service compared to traditional designs.

Properly caring for your air compressor helps you lower your operating costs and minimizes the risk for unplanned breakdowns or production stops. Atlas Copco offers energy efficiency checks, service, repairs, air compressor spare parts and maintenance plans for all air compressors. Entrust your servicing to our expert professionals and ensure your business continues to run efficiently. Our plans cover repairs, preventative maintenance, spare parts, and more.

Designed for serviceability

Ease of maintenance

- Service parts grouped together for ease of access.

- Reduced service time for greater uptime.

- Portable design enables full access to all components.

- All components designed for serviceability.

- Oil cooled motors require no service interventions.

Compressor oils, lubricants and fluids

Every type of compressor and vacuum pump needs a specific oil to achieve maximum uptime, performance and lifetime. Our compressed air fluids and lubricants coverall your needs.

Unique mix of additives

Tailored to the specific needs of your equipment.

Anti-oxidation

The high-quality oil ensures maximum protection.

Prevent foaming

Anti-foaming improves your air quality.

Maximize your resources with a Service Plan

Reduce your total cost of ownership and benefit from optimal performance

Save costs

Optimal maintenance will reduce the operational cost of your compressed air and vacuum system.

Increase operational efficiency

Our maintenance expertise makes life easier when it comes to resource management.

High uptime and performance

Specialist service keeps your equipment running as it should, protecting your investment.

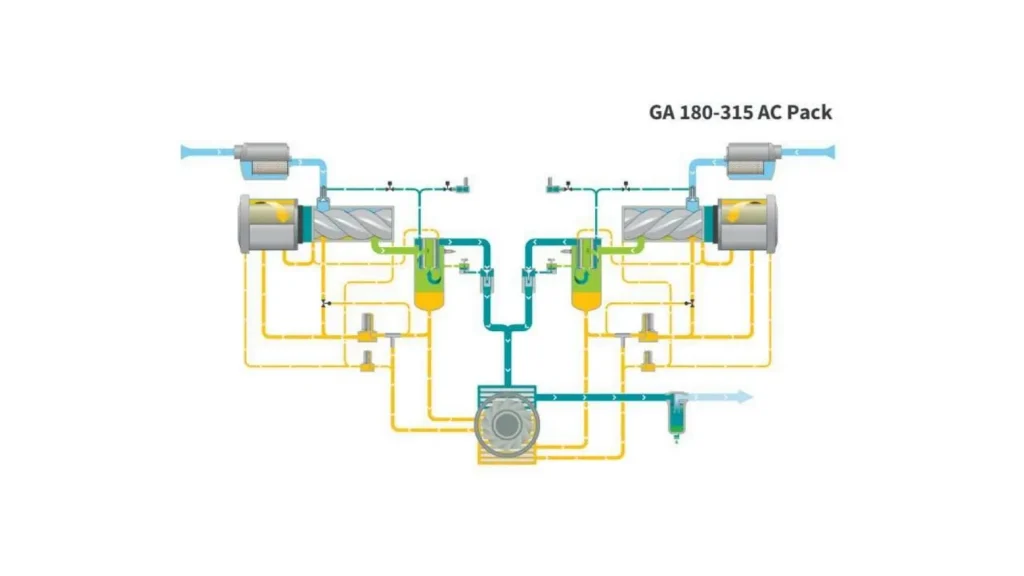

GA 180-315 VSD+ Flowchart

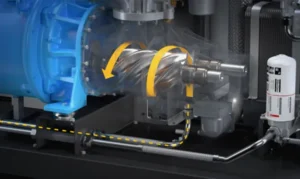

1. Filtration & compression

The air is drawn into the compressor through the inlet filter and is compressed in the oil injected rotary screw compression element via the air intake (load-unload) valve. Lubrication fluid is injected during the compression phase into the air. This not only reduces the wear of the elements but also cools them.

2. Air & oil separation

The compressed air/oil mixture passes through a non- return valve to the oil separator element to separate the oil from the air. The wet compressed air, represented by the dark blue/ greethen passes through a minimum pressure valve and is cooled by an air-cooled aftercooler.

3. Cooling

Low noise axial cooling fans provide cooling air to the oil cooler and after cooler, ensuring satisfactory running temperatures as well as ventilating the compressor enclosure.

4. Moisture separator

The condensed moisture is removed by a low pressure drop moisture separator and electronic condensate drain. This results in dry compressed air is that can be used in your application.

5. Oil flow

Lubrication fluid contained in the oil receiver flows under differential pressure to a thermostatic bypass valve, air cooled oil cooler, high efficiency oil filter and oil stop valve before being injected into the compression element where it cools, seals and lubricates the compression process.The high efficiency oil filter provides superior filtration compared to conventional filters resulting in cleaner lubricant. The thermostatic bypass valve ensures that the compressor quickly reaches optimum operating temperature on start-up and maintains temperature during periods of low load by allowing cold lubricant to bypass the oil cooler.

GA 180-315 VSD+ Technical specifications

GA 180 – 315 (VSD+) (50 Hz)

|

Type |

Maximum working pressure | Capacity FAD (1) | Installed motor power | Noise level (2) | Weight | ||||||||

| Standard | Full Feature (3) | Standard / Full Feature (3) | Standard | Full Feature (3) | |||||||||

| bar(e) | psig | bar(e) | psig | l/s | m³/min | cfm | kW | dB(A) | kg | lb | kg | lb | |

| GA 180 – 5.5 bar | 5.5 | 80 | 5.3 | 77 | 690 | 41.4 | 1462 |

180 |

70 |

5700 |

12566 |

6400 | 14110 |

| GA 180 – 7.5 bar | 7.5 | 109 | 7.3 | 106 | 585 | 35.1 | 1240 | 70 | |||||

| GA 180 – 8.5 bar | 8.5 | 123 | 8.3 | 120 | 558 | 33.5 | 1182 | 67 | 6300 | 13889 | |||

| GA 180 – 10 bar | 10 | 145 | 9.8 | 142 | 510 | 30.6 | 1081 | 68 | |||||

| GA 200 – 5.5 bar | 5.5 | 80 | 5.3 | 77 | 833.2 | 50.0 | 1765 |

220 |

71 |

5900 |

13007 |

6500 |

14330 |

| GA 200 – 7.5 bar | 7.5 | 109 | 7.3 | 106 | 729 | 43.7 | 1545 | 74 | |||||

| GA 200 – 8.5 bar | 8.5 | 123 | 8.3 | 120 | 686 | 41.2 | 1454 | 70 | |||||

| GA 200 – 10 bar | 10 | 145 | 9.8 | 142 | 624 | 37.4 | 1322 | 70 | |||||

| GA 250 – 5.5 bar | 5.5 | 80 | 5.3 | 77 | 985 | 59.1 | 2087 |

264 |

76 |

6000 |

13228 |

6700 |

14771 |

| GA 250 – 7.5 bar | 7.5 | 109 | 7.3 | 106 | 868 | 52.1 | 1839 | 75 | |||||

| GA 250 – 8.5 bar | 8.5 | 123 | 8.3 | 120 | 817 | 49.0 | 1731 | 71 | |||||

| GA 250 – 10 bar | 10 | 145 | 9.8 | 142 | 754 | 45.2 | 1598 | 71 | |||||

| GA 315 – 7.5 bar | 7.5 | 109 | 73 | 106 | 1036 | 62.2 | 2072 |

320 |

73 |

6200 |

13669 |

6800 |

14991 |

| GA 315 – 8.5 bar | 8.5 | 123 | 8.3 | 120 | 978 | 58.7 | 2072 | 73 | |||||

| GA 315 – 10 bar | 10 | 145 | 9.8 | 142 | 911 | 54.7 | 1930 | 70 | |||||

| GA 200 VSD+ 8.5 bar | 8.5 | 123 | 8.3 | 120 | 195-725 | 12-43.5 | 413-1536 | 220 | 73 | 5000 | 11023 | 5700 | 12566 |

| GA 200 VSD+ 10 bar | 10 | 145 | 9.8 | 142 | 193-665 | 11.5-40 | 409-1409 | 67 | 5100 | 11244 | 5600 | 12346 | |

| GA 250 VSD+ 8.5 bar | 8.5 | 123 | 8.3 | 120 | 195-865 | 12-51.9 | 413-1833 | 264 | 71 | 5200 | 11464 | 5800 | 12787 |

| GA 250 VSD+ 10 bar | 10 | 145 | 9.8 | 142 | 193-782 | 11.5-47 | 409-1657 | 75 | 5200 | 11464 | 5800 | 12787 | |

| GA 315 VSD+ 8.5 bar | 8.5 | 123 | 8.3 | 120 | 195-1032 | 12-61.9 | 413-2187 | 320 | 77 | 5200 | 11464 | 5900 | 13007 |

| GA 315 VSD+ 10 bar | 10 | 145 | 9.8 | 142 | 193-955 | 11.5-57.3 | 409-2023 | 77 | 5200 | 11464 | 5900 | 13007 | |

| GA200 VSDΔ – 7.5 bar | 7.5 | 109 | 7.3 | 106 | 100-750 | 6-45 | 212-1590 | 222 | 73 | 5500 | 12125 | 6100 | 13448 |

| GA200 VSDΔ – 8.5 bar | 8.5 | 123 | 8.3 | 120 | 100-715 | 6-43 | 212-1515 | 222 | 73 | 5500 | 12125 | 6100 | 13448 |

| GA200 VSDΔ – 10 bar | 10 | 145 | 9.8 | 142 | 100-642 | 6-38.5 | 212-1360 | 222 | 73 | 5500 | 12125 | 6100 | 13448 |

| GA250 VSDΔ – 7.5 bar | 7.5 | 109 | 7.3 | 106 | 100-912 | 6-54.7 | 212-1932 | 270 | 77 | 5600 | 12346 | 6200 | 13669 |

| GA250 VSDΔ – 8.5 bar | 8.5 | 123 | 8.3 | 120 | 100-860 | 6-51.6 | 212-1822 | 270 | 77 | 5600 | 12346 | 6200 | 13669 |

| GA250 VSDΔ – 10 bar | 10 | 145 | 9.8 | 142 | 100-785 | 6-47 | 212-1663 | 270 | 77 | 5600 | 12346 | 6200 | 13669 |

FAD(1) is measured at the following working pressures:

| Standard | |

| 5.5 bar (75 psi) version at | 5 bar (73 psi) |

| 7.5 bar (100 psi) version at | 7 bar (100 psi) |

| 8.5 bar (125 psi) version at | 8 bar (125 psi) |

| 10 bar (150 psi) version at | 9.5 bar (150 psi) |

GA 180 – 315 (VSD+) (60 Hz)

|

TYPE |

Maximum working pressure | Capacity FAD (1) | Installed motor power | Noise level (2) | Weight | ||||||||

| Standard | Full Feature (3) | Standard / Full Feature (3) | Standard | Full Feature (3) | |||||||||

| bar(e) | psig | bar(e) | psig | l/s | m³/min | cfm | hp | dB(A) | kg | lb | kg | lb | |

| GA 180 – 75 psi | 5.5 | 80 | 5.3 | 77 | 622 | 37.3 | 1318 |

240 |

74 | 6000 | 13228 |

6800 |

14991 |

| GA 180 – 100 psi | 7.4 | 107 | 7.2 | 104 | 596 | 35.8 | 1263 | 76 |

6200 |

13669 |

|||

| GA 180 – 125 psi | 9.1 | 132 | 8.9 | 129 | 536 | 32.2 | 1136 | 73 | |||||

| GA 180 – 150 psi | 10.9 | 158 | 10.7 | 155 | 479 | 28.7 | 1015 | 75 | |||||

| GA 200 – 75 psi | 5.5 | 80 | 5.3 | 77 | 836 | 50.2 | 1771 |

295 |

77 |

5700 |

12566 |

6400 |

14110 |

| GA 200 – 100 psi | 7.4 | 107 | 7.2 | 104 | 735 | 44.1 | 1557 | 76 | |||||

| GA 200 – 125 psi | 9.1 | 132 | 8.9 | 129 | 660 | 39.6 | 1398 | 76 | |||||

| GA 200 – 150 psi | 10.9 | 158 | 10.7 | 155 | 591 | 35.5 | 1252 | 75 | |||||

| GA 250 – 75 psi | 5.5 | 80 | 5.3 | 77 | 991 | 59.5 | 2100 |

355 |

78 |

5900 |

13007 |

6500 |

14330 |

| GA 250 – 100 psi | 7.4 | 107 | 7.2 | 104 | 879 | 52.7 | 1862 | 77 | |||||

| GA 250 – 125 psi | 9.1 | 132 | 8.9 | 129 | 791 | 47.5 | 1676 | 74 | |||||

| GA 250 – 150 psi | 10.9 | 158 | 10.7 | 155 | 701 | 42.1 | 1485 | 75 | |||||

| GA 315 – 100 psi | 7.4 | 107 | 7.2 | 104 | 1043 | 62.6 | 2210 |

430 |

76 |

6000 |

13228 |

6700 |

14771 |

| GA 315 – 125 ps | 9.1 | 132 | 8.9 | 129 | 950 | 57.0 | 2013 | 76 | |||||

| GA 315 – 150 psi | 10.9 | 158 | 10.7 | 155 | 873 | 52.4 | 1850 | 76 | |||||

| GA 200 VSD+ 125 psi | 9.1 | 132 | 8.9 | 129 | 194-706 | 11.6-42.3 | 411-1496 | 295 | 72 | 5000 | 11023 | 5700 | 12566 |

| GA 200 VSD+ 150 psi | 10.9 | 158 | 10.7 | 155 | 190-630 | 11.4-37.8 | 403-1335 | 69 | |||||

| GA 250 VSD+ 125 psi | 9.1 | 132 | 8.9 | 129 | 194-840 | 11.6-50.4 | 411-1780 | 355 | 70 | 5200 | 11464 | 5800 | 12787 |

| GA 250 VSD+ 150 psi | 10.9 | 158 | 10.7 | 155 | 190-755 | 11.4-45.3 | 403-1600 | 73 | |||||

| GA 315 VSD+ 125 psi | 9.1 | 132 | 8.9 | 129 | 194-1004 | 11.6-60.2 | 411-2127 | 430 | 76 | 5300 | 11684 | 5900 | 13007 |

| GA 315 VSD+ 150 psi | 10.9 | 158 | 10.7 | 155 | 190-910 | 11.4-54.6 | 403-1928 | 76 | |||||

| GA200 VSDΔ – 100 psi | 7.4 | 107 | 7.2 | 104 | 212-1614 | 100-762 | 6-45.7 |

297 |

72 |

5700 |

12566.33 |

6300 |

13889 |

| GA200 VSDΔ – 125 psi | 9.1 | 132 | 8.9 | 129 | 208-1455 | 98-687 | 5.8-41 | 72 | |||||

| GA200 VSDΔ – 150 psi | 10.9 | 158 | 10.7 | 155 | 200-1299 | 94-613 | 5.6-36.7 | 72 | |||||

| GA250 VSDΔ – 100 psi | 7.4 | 107 | 7.2 | 104 | 212-1945 | 100-918 | 6-55 |

362 |

76 |

5700 |

12566.33 |

6300 |

13889 |

| GA250 VSDΔ – 125 psi | 8.9 | 132 | 8.9 | 129 | 208-1758 | 98-830 | 5.8-50 | 76 | |||||

| GA250 VSDΔ – 150 psi | 10.9 | 158 | 10.7 | 155 | 200-1580 | 94-746 | 5.6-44.7 | 76 | |||||

FAD(1) is measured at the following working pressures:

| Standard | FF | |

| 75 psi version at | 73 psi | 73 psi |

| 100 psi version at | 100 psi | 100 psi |

| 125 psi version at | 125 ps | 125 psi |

| 150 psi version at | 150 psi | 150 psi |

Dimensions

| L | W | H | ||||

| mm | inch | mm | inch | mm | inch | |

| GA 180 – 315 (VSD+) Pack (Air cooled) | 4390 | 173 | 2090 | 82 | 2020 | 79 |

| GA 180 – 315 (VSD+) Full Feature (Air cooled) | 5020 | 198 | 2090 | 82 | 2020 | 79 |

| GA 180 – 315 (VSD+) Pack (Water cooled) | 3760 | 148 | 2090 | 82 | 2020 | 79 |

| GA 180 – 315 (VSD+) Full Feature (Water cooled) | 4390 | 173 | 2090 | 82 | 2020 | 79 |

Atlas Copco GA 180-315 VSD+ FAQ

1. What applications is the GA 180-315 VSD+ series air compressor suitable for?

-

This series is ideal for industries such as automotive manufacturing, metal processing, electronics, food & beverage, textiles, and chemicals, especially for applications requiring a stable and efficient compressed air supply.

2. What energy-saving technologies are used in the GA 180-315 VSD+ series?

-

Equipped with Variable Speed Drive Plus (VSD+) technology, which adjusts motor speed based on air demand to reduce energy consumption.

-

Features an iPM (integrated Permanent Magnet) motor for enhanced energy efficiency.

-

Optimized cooling system to lower power consumption and improve overall operational efficiency.

3. What is the maintenance schedule and servicing requirement for this series?

-

Due to its advanced oil-lubricated screw technology, the maintenance cycle is relatively long, typically requiring routine servicing every 4,000-8,000 hours.

-

Maintenance includes replacing air filters, oil filters, and lubricants like 2901170100 , as well as checking the cooling system and motor condition.

4. Does the GA 180-315 VSD+ series support remote monitoring?

-

Yes, this series supports Atlas Copco SMARTLINK remote monitoring, allowing users to manage compressor status, energy efficiency data, and maintenance alerts via a cloud-based system.

5. Is an integrated dryer option available?

-

Yes, the Full Feature (FF) version of the GA 180-315 VSD+ series includes a built-in refrigerant dryer, ensuring high-quality compressed air with a dew point of 3°C (37°F).

Welcome to download the Atlas Copco GA 180-315 VSD+ Air Compressors Brochure: Atlas Copco GA 180-315 VSD+ Air Compressors Sales Leaflet EN

Anonymous –

excellent compressor!

We have been using this Atlas Copco air compressor for over a year, and it has exceeded our expectations. The build quality is outstanding, and it has proven to be extremely durable, even under heavy use. Unlike previous compressors we’ve owned, this one requires very little maintenance, which saves us both time and money. The energy efficiency is another big plus, reducing our power consumption significantly. It operates quietly and consistently, making our workflow much smoother. Overall, this is one of the best compressors on the market, and I would definitely recommend it to anyone in need of a reliable unit.