The Atlas Copco G 90-355 (VSD) Air compressors include models G 90, G 110, G 132, G 160, G 180, G 200, G 250, G 315, and G 355. These innovative compressors are designed for high efficiency and variable load operation, making them ideal for diverse industrial environments. Equipped with advanced Variable Speed Drive (VSD) technology, they adjust compressed air output based on actual demand, significantly reducing energy consumption and operational costs. Their reliable, energy-efficient, and low-maintenance design ensures long-term stability, enhancing productivity and overall business efficiency.

Contents

- 1 Atlas Copco G 90-355 (VSD) Air Compressors: Reliability, efficiency and simplicity

- 2 VSD: Driving down your energy costs

- 3 What is unique about the integrated Atlas Copco G VSD?

- 4 Atlas Copco G 90-355 (VSD) Air Compressors Flow chart

- 5 Optimize your system

- 6 Atlas Copco G 90-355 (VSD) Air Compressors Technical Data

- 7 Atlas Copco G 90-355 (VSD) Air Compressors FAQ

- 7.1 1.What is VSD technology, and how does it benefit energy consumption?

- 7.2 2.Can the G 90-355 (VSD) compressors handle varying air demand?

- 7.3 3.What maintenance is required for the G 90-355 (VSD) series?

- 7.4 4.What are the space-saving features of these compressors?

- 7.5 5.How does the Elektronikon® MK5 control system optimize compressor performance?

- 8 Inquiry Now

Atlas Copco G 90-355 (VSD) Air Compressors: Reliability, efficiency and simplicity

1.Smaller footprints

• Smaller footprint than all competitors.

• Save more installation space, increase capacity in limited installation space.

2.State-of-the-art screw element

• Atlas Copco designed and patented asymmetric element profile with high quality bearings offering low wear and increased reliability.

• The unique profile design provides industry leading energy efficiency to lower your operating cost.

3.High-efficiency cooler

•Element outlet temperature is optimized, avoid machine shut down due to element high temperature, increase reliability.

•Stainless cooler bundle avoid corrosion for water cooled machine.

•Optimized design reduces maintenance cost and increases reliability.

4.Superior air-oil separation

• Reduction of pressure drops and energy costs.

• Low oil consumption ensures minimal maintenance costs and long compressor lifetime.

• Optimized design of vessel to reduce the oil carry over, increase reliability.

5.High-efficiency motor

• High-efficiency (IE3) motor (Class F insulation) adapted to harshest conditions.

• Long-termstable operation even in harsh environments.

6.Optimal control with the Elektronikon® MK5 & SmartLink

• Clear icons and intuitive navigation provide you with fast access to all of the important settings and data.

• Monitoring of the equipment running conditions and maintenance status..

• SmartLink provides remote monitoring of compressor running status.

VSD: Driving down your energy costs

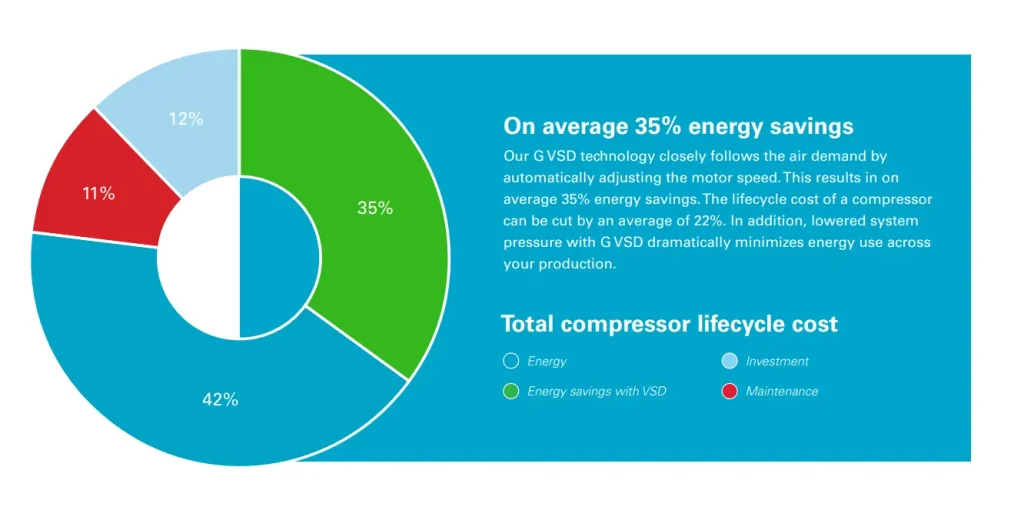

Over 70% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. Atlas Copco was thefirst compressor manufacturer to introduce compressors with integrated Variable Speed Drive (VSD). With over 20 years of design and manufacturing experience our VSD technology has reached new heights of energy savings and reliability. VSD technology reduces energy consumption in systems that have varying air demand patterns. This reduction in energy consumption not only reduces your energy consumption but also your carbon footprint to help protect the environment for generations to come.

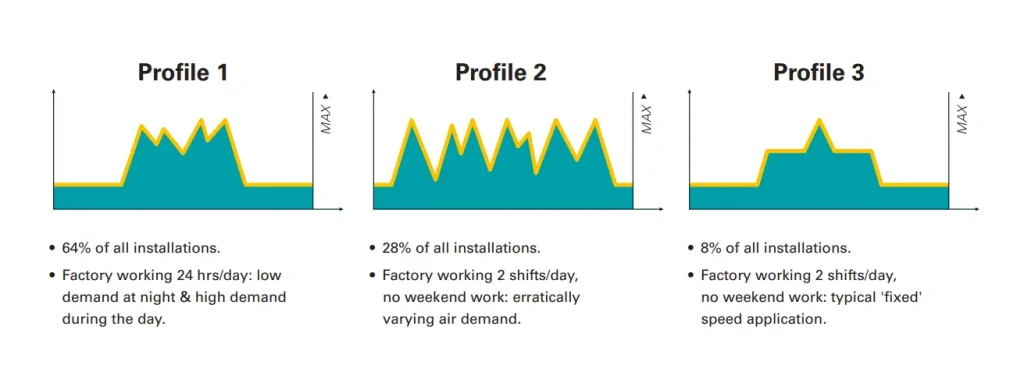

Why VSD technology?

In almost every production environment, air demand fluctuates depending on different factors (time of the day, week or even month). Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand. Only 8% of all installations have a more stable air demand. Tests prove that, even in this case, VSD compressors save energy.

Find out how much you can save

We can help you map the air demand profile of your current compressor installation and indicate potential energy savings with VSD compressors. For more information, please contact Atlas Copco air compressor supplier like Seadweer.

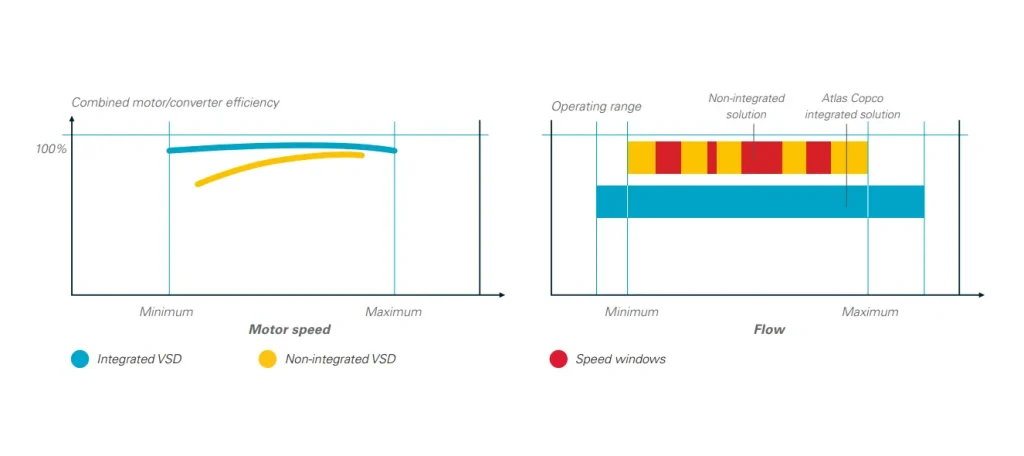

What is unique about the integrated Atlas Copco G VSD?

1. The Elektronikon® controls both the compressor and the integrated converter, ensuring maximum machine safety within parameters.

2. Flexible pressure selection from 4 to 10 bar with electronic gearing reduces electricity costs.

3. Specific converter and motor design (with protected bearings) for the highest efficiency across the speed range.

4. Electric motor specifically designed for low operating speeds with clear attention to motor cooling and compressor cooling requirements.

5. All Atlas Copco G VSD compressors are EMC tested and certified. Compressor operation does not influence external sources and vice versa.

6. Mechanical enhancements ensure that all components operate below critical vibration levels throughout the entire compressor speed range.

7. No ‘speed windows’ that can jeopardize energy savings or the stability of the net pressure. FAD range: 30-100%.

8. Net pressure band is maintained within 0.10 bar, 1.5 psi.

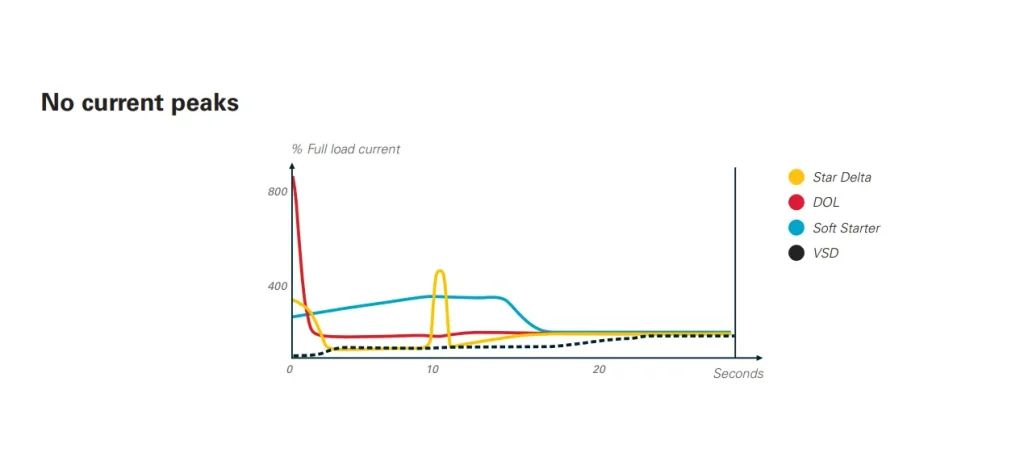

No current peaks

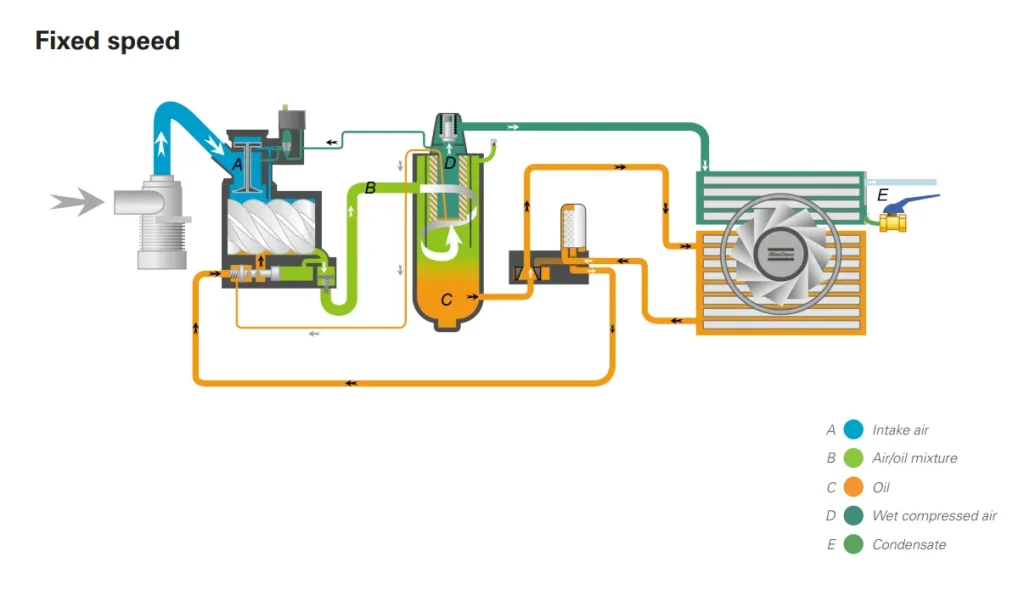

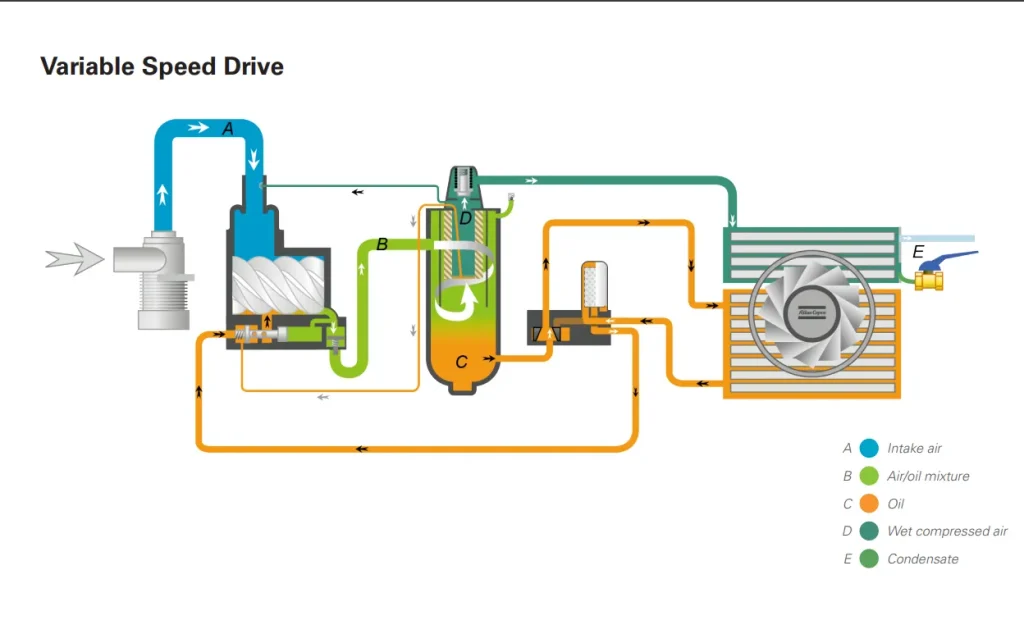

Atlas Copco G 90-355 (VSD) Air Compressors Flow chart

Fixed speed

Variable Speed Drive

Optimize your system

Scope of supply

• Air inlet filter and flexibles

• Air intake valve

• Full load/no load regulator

• Long lifetime filtration and separation elements

• G/DIN connection for 50Hz unit, NPT/ANSI for 60Hz unit

• Heavy-duty oil filters

• Air-oil separator

• Compressed air aftercooler and oil cooler

• ASME/ML/AS1210/MOM approvals

• SmartLink

Options

• Performance test certificate

• Witness performance test

• Seaworthy packing

Dimensions

| TYPE | Dimensions (Air-cooled) | |||||

| L | W | H | ||||

| L (mm) | L (inch) | W (mm) | W (inch) | H (mm) | H (inch) | |

| G 90-132 (VSD) | 1900 | 75 | 1200 | 47 | 2000 | 79 |

| G 160 Pro (VSD) | 2800 | 110 | 1600 | 63 | 2000 | 79 |

| G 200-250 Pro (VSD) | 2800 | 110 | 1600 | 63 | 2300 | 91 |

| G 250L-355 Pro (VSD) | 3400 | 134 | 1750 | 69 | 2400 | 94 |

| TYPE | Dimensions (Air-cooled) | |||||

| L | W | H | ||||

| L (mm) | L (inch) | W (mm) | W (inch) | H (mm) | H (inch) | |

| G 90-132 (VSD) | 1900 | 75 | 1200 | 47 | 2000 | 79 |

| G 160-250 Pro (VSD) | 2800 | 110 | 1600 | 63 | 2000 | 79 |

| G 250L-355 Pro (VSD) | 3400 | 134 | 1750 | 69 | 2000 | 79 |

Atlas Copco G 90-355 (VSD) Air Compressors Technical Data

Technical data 50 Hz

| TYPE | Maximum working pressure | Capacity FAD (1) | Installed motor power | Air Outlet Size | Weight (shipping mass) | |||||

| Standard | Pack | Standard | ||||||||

| bar(e) | psig | l/s | m3/min | cfm | kW | HP | KG | lbs | ||

| 50 Hz | ||||||||||

| G 90-7.5 | 7.5 | 109 | 294 | 17.6 | 623 | 90 | 125 | G2-1/2” | 1900 | 4189 |

| G 90-8.5 | 8.5 | 123 | 270 | 16.2 | 571 | 90 | 125 | G2-1/2” | 1900 | 4189 |

| G 90-10 | 10 | 145 | 254 | 15.3 | 539 | 90 | 125 | G2-1/2” | 1900 | 4189 |

| G 90-14 | 14 | 203 | 217 | 13 | 460 | 90 | 125 | G2-1/2” | 1900 | 4189 |

| G 110-7.5 | 7.5 | 109 | 335 | 20.1 | 710 | 110 | 150 | G2-1/2” | 2000 | 4409 |

| G 110-8.5 | 8.5 | 123 | 314 | 18.8 | 664 | 110 | 150 | G2-1/2” | 2000 | 4409 |

| G 110-10 | 10 | 145 | 290 | 17.4 | 614 | 110 | 150 | G2-1/2” | 2000 | 4409 |

| G 110-14 | 14 | 203 | 247 | 14.8 | 523 | 110 | 150 | G2-1/2” | 2000 | 4409 |

| G 132-7.5 | 7.5 | 109 | 404 | 24.2 | 855 | 132 | 175 | G2-1/2” | 2100 | 4630 |

| G 132-8.5 | 8.5 | 123 | 383 | 23 | 811 | 132 | 175 | G2-1/2” | 2100 | 4630 |

| G 132-10 | 10 | 145 | 344 | 20.7 | 729 | 132 | 175 | G2-1/2” | 2100 | 4630 |

| G 132-14 | 14 | 203 | 302 | 18.1 | 640 | 132 | 175 | G2-1/2” | 2100 | 4630 |

| G 160-7.5 Pro | 7.5 | 109 | 516.7 | 31 | 1095 | 160 | 215 | DN100 | 3973 | 8759 |

| G 160-8.5 Pro | 8.5 | 123 | 500 | 30 | 1059 | 160 | 215 | DN100 | 3973 | 8759 |

| G 160-10 Pro | 10 | 145 | 450 | 27 | 953 | 160 | 215 | DN100 | 3973 | 8759 |

| G 160-14 Pro | 14 | 203 | 380 | 22.8 | 805 | 160 | 215 | DN100 | 3973 | 8759 |

| G 180-7.5 Pro | 7.5 | 109 | 603.4 | 36.2 | 1279 | 180 | 241 | DN100 | 4213 | 9288 |

| G 180-8.5 Pro | 8.5 | 123 | 583.3 | 35 | 1236 | 180 | 241 | DN100 | 4213 | 9288 |

| G 180-10 Pro | 10 | 145 | 511.7 | 30.7 | 1084 | 180 | 241 | DN100 | 4213 | 9288 |

| G 180-14 Pro | 14 | 203 | 411.7 | 24.7 | 872 | 180 | 241 | DN100 | 4213 | 9288 |

| G 200-7.5 Pro | 7.5 | 109 | 693.4 | 41.6 | 1469 | 200 | 268 | DN100 | 4298 | 9475 |

| G 200-8.5 Pro | 8.5 | 123 | 670 | 40.2 | 1420 | 200 | 268 | DN100 | 4298 | 9475 |

| G 200-10 Pro | 10 | 145 | 591.6 | 35.5 | 1254 | 200 | 268 | DN100 | 4298 | 9475 |

| G 200-14 Pro | 14 | 203 | 495 | 29.7 | 1049 | 200 | 268 | DN100 | 4298 | 9475 |

| G 250-7.5 Pro | 7.5 | 109 | 750 | 45 | 1589 | 250 | 335 | DN100 | 4513 | 9949 |

| G 250-8.5 Pro | 8.5 | 123 | 750 | 45 | 1589 | 250 | 335 | DN100 | 4513 | 9949 |

| G 250-10 Pro | 10 | 145 | 673.4 | 40.4 | 1427 | 250 | 335 | DN100 | 4513 | 9949 |

| G 250-14 Pro | 14 | 203 | 568.3 | 34.1 | 1204 | 250 | 335 | DN100 | 4513 | 9949 |

| G 250L-7.5 Pro | 7.5 | 109 | 890 | 53.4 | 1886 | 250 | 335 | DN125 | 6760 | 14903 |

| G 250L-8.5 Pro | 8.5 | 123 | 844 | 50.6 | 1788 | 250 | 335 | DN125 | 6760 | 14903 |

| G 250L-10 Pro | 10 | 145 | 785 | 47.1 | 1662 | 250 | 335 | DN125 | 6760 | 14903 |

| G 250L-14 Pro | 14 | 203 | 650 | 39 | 1378 | 250 | 335 | DN125 | 6760 | 14903 |

| G 315-7.5 Pro | 7.5 | 109 | 1049 | 62.9 | 2222 | 315 | 422 | DN125 | 6790 | 14969 |

| G 315-8.5 Pro | 8.5 | 123 | 1002 | 60.1 | 2123 | 315 | 422 | DN125 | 6790 | 14969 |

| G 315-10 Pro | 10 | 145 | 916 | 55 | 1941 | 315 | 422 | DN125 | 6790 | 14969 |

| G 315-14 Pro | 14 | 203 | 750 | 45 | 1589 | 315 | 422 | DN125 | 6790 | 14969 |

| *G 355-7.5 Pro | 7.5 | 109 | 1093 | 65.6 | 2316 | 355 | 476 | DN125 | 7130 | 15719 |

| G 355-8.5 Pro | 8.5 | 123 | 1093 | 65.6 | 2316 | 355 | 476 | DN125 | 7130 | 15719 |

| G 355-10 Pro | 10 | 145 | 1000 | 60 | 2120 | 355 | 476 | DN125 | 7130 | 15719 |

| G 355-14 Pro | 14 | 203 | 834 | 50 | 1766 | 355 | 476 | DN125 | 7130 | 15719 |

* G 355-7.5 Pro FAD is 1140 l/s for water cooled version(1)

Unit performance : Measured according to ISO1217 Reference conditions:

– Absolute inlet pressure 1 bar (14,5psi)

– Intake air temperature 20°C (68°F)

– Cooling medium temperature 20°C (68°F)

FAD is measured at the following working pressures:

• 7.5 bar variants at 7 bar

• 8.5 bar variants at 8 bar

• 10 bar variants at 10 bar

• 14 bar variants at 12.5 bar

Technical data 50 Hz VSD

| TYPE | Maximum working pressure | Capacity FAD (1) | Installed motor power | Air Outlet Size | Weight (shipping mass) | |||||

| Standard | Pack | Standard | ||||||||

| bar(e) | psig | l/s | m3/min | cfm | kW | HP | KG | lbs | ||

| 50 Hz | ||||||||||

| G 110 VSD-10 | Minimum | 4 | 58 | 77-335 | 4.6-20.1 | 163-710 | 110 | 150 | G2-1/2” | 2100 4630 |

| G 110 VSD-10 | 7 | 102 | 77-334 | 4.6-20.1 | 163-708 | 110 | 150 | G2-1/2” | 2100 4630 | |

| G 110 VSD-10 | 8 | 116 | 76-317 | 4.6-19 | 161-672 | 110 | 150 | G2-1/2” | 2100 4630 | |

| G 110 VSD-10 | Maximum | 10 | 138 | 76-287 | 4.5-17.2 | 160-607 | 110 | 150 | G2-1/2” | 2100 4630 |

| G 110 VSD-14 | Maximum | 14 | 203 | 83-244 | 5-14.6 | 176-516 | 110 | 150 | G2-1/2” | 2100 4630 |

| G 132 VSD-10 | Minimum | 4 | 58 | 110-398 | 6.6-23.9 | 233-843 | 132 | 175 | G2-1/2” | 2200 4850 |

| G 132 VSD-10 | 7 | 102 | 109-397 | 6.6-23.8 | 231-842 | 132 | 175 | G2-1/2” | 2200 4850 | |

| G 132 VSD-10 | 8 | 116 | 108-378 | 6.5-22.7 | 230-800 | 132 | 175 | G2-1/2” | 2200 4850 | |

| G 132 VSD-10 | Maximum | 10 | 138 | 108-342 | 6.5-20.5 | 229-724 | 132 | 175 | G2-1/2” | 2200 4850 |

| G 132 VSD-14 | Maximum | 14 | 203 | 112-288 | 6.7-17.3 | 238-611 | 132 | 175 | G2-1/2” | 2200 4850 |

| G 160VSD-10 Pro | 10 | 145 | 201.9-543.3 | 12.1-32.6 | 428-1151 | 160 | 215 | DN100 | 3570 7871 | |

| G 160VSD-14 Pro | 14 | 203 | 202.3-461.6 | 12.1-27.7 | 429-978 | 160 | 215 | DN100 | 3570 7871 | |

| G 180VSD-10 Pro | 10 | 145 | 198.3-613.4 | 11.9-36.8 | 420-1300 | 180 | 241 | DN100 | 3607 7952 | |

| G 180VSD-14 Pro | 14 | 203 | 199.6-516.6 | 12.0-31.0 | 423-1095 | 180 | 241 | DN100 | 3607 7952 | |

| G 200VSD-10 Pro | 10 | 145 | 198.4-706.7 | 11.9-42.4 | 420-1497 | 200 | 268 | DN100 | 3617 7974 | |

| G 200VSD-14 Pro | 14 | 203 | 254.1-600 | 15.2-36.0 | 538-1271 | 200 | 268 | DN100 | 3617 7974 | |

| G 250VSD-10 Pro | 10 | 145 | 198.5-750 | 11.9-45.0 | 421-1589 | 250 | 335 | DN100 | 3792 8360 | |

| G 250VSD-14 Pro | 14 | 203 | 200.4-651.7 | 12.0-39.1 | 425-1381 | 250 | 335 | DN100 | 3792 8360 | |

| G 250LVSD-10 Pro | 10 | 145 | 277-883 | 16.6-53.0 | 587-1872 | 250 | 335 | DN125 | 6495 14319 | |

| G 250LVSD-14 Pro | 14 | 203 | 267-750 | 16.0-45.0 | 566-1589 | 250 | 335 | DN125 | 6495 14319 | |

| G 315VSD-10 Pro | 10 | 145 | 352-1050 | 21.1-63.0 | 746-2225 | 315 | 422 | DN125 | 6740 14859 | |

| G 315VSD-14 Pro | 14 | 203 | 345-939 | 20.7-56.3 | 731-1989 | 315 | 422 | DN125 | 6740 14859 | |

| *G 355VSD-10 Pro | 10 | 145 | 351-1090 | 21.1-65.4 | 744-2310 | 355 | 476 | DN125 | 6750 14881 | |

| G 355VSD-14 Pro | 14 | 203 | 345-1020 | 20.7-61.2 | 731-2162 | 355 | 476 | DN125 | 6750 14881 | |

* G 355VSD-10 Pro max FAD is up to 1140 l/s for water cooled version

(1) Unit performance : Measured according to ISO1217

Reference conditions:

– Absolute inlet pressure 1 bar (14,5psi)

– Intake air temperature 20°C (68°F)

– Cooling medium temperature 20°C (68°F)

FAD is measured at the following working pressures:

• 10 bar variants between 7 to 10 bar

• 14 bar variants between 10 to 14 bar

Technical Data 60 Hz

| TYPE | Maximum working pressure | Capacity FAD (1) | Installed motor power | Air Outlet Size | Weight (shipping mass) | |||||

| Standard | Pack | Standard | ||||||||

| bar(e) | psig | l/s | m3/min | cfm | kW | HP | KG | lbs | ||

| 60 Hz | ||||||||||

| G 90-7.5 | 7.5 | 109 | 298 | 17.9 | 632 | 90 | 125 | NPT 2-1/2” | 1900 | 4189 |

| G 90-8.5 | 8.5 | 123 | 269 | 16.1 | 569 | 90 | 125 | NPT 2-1/2” | 1900 | 4189 |

| G 90-10 | 10 | 145 | 254 | 15.2 | 537 | 90 | 125 | NPT 2-1/2” | 1900 | 4189 |

| G 90-14 | 14 | 203 | 223 | 13.4 | 472 | 90 | 125 | NPT 2-1/2” | 1900 | 4189 |

| G 110-7.5 | 7.5 | 109 | 332 | 19.9 | 704 | 110 | 150 | NPT 2-1/2” | 2000 | 4409 |

| G 110-8.5 | 8.5 | 123 | 313 | 18.8 | 664 | 110 | 150 | NPT 2-1/2” | 2000 | 4409 |

| G 110-10 | 10 | 145 | 288 | 17.3 | 610 | 110 | 150 | NPT 2-1/2” | 2000 | 4409 |

| G 110-14 | 14 | 203 | 248 | 14.9 | 525 | 110 | 150 | NPT 2-1/2” | 2000 | 4409 |

| G 132-7.5 | 7.5 | 109 | 403 | 24.2 | 853 | 132 | 175 | NPT 2-1/2” | 2100 | 4630 |

| G 132-8.5 | 8.5 | 123 | 383 | 23 | 811 | 132 | 175 | NPT 2-1/2” | 2100 | 4630 |

| G 132-10 | 10 | 145 | 346 | 20.8 | 733 | 132 | 175 | NPT 2-1/2” | 2100 | 4630 |

| G 132-14 | 14 | 203 | 313 | 18.8 | 663 | 132 | 175 | NPT 2-1/2” | 2100 | 4630 |

| G 160-7.5 Pro | 7.5 | 109 | 521.6 | 31.3 | 1105 | 160 | 215 | ANSI 4″ | 3973 | 8759 |

| G 160-8.5 Pro | 8.5 | 123 | 503.3 | 30.2 | 1066 | 160 | 215 | ANSI 4″ | 3973 | 8759 |

| G 160-10 Pro | 10 | 145 | 460 | 27.6 | 975 | 160 | 215 | ANSI 4″ | 3973 | 8759 |

| G 160-14 Pro | 14 | 203 | 376.7 | 22.6 | 798 | 160 | 215 | ANSI 4″ | 3973 | 8759 |

| G 180-7.5 Pro | 7.5 | 109 | 595 | 35.7 | 1261 | 180 | 241 | ANSI 4″ | 4213 | 9288 |

| G 180-8.5 Pro | 8.5 | 123 | 583.3 | 35 | 1236 | 180 | 241 | ANSI 4″ | 4213 | 9288 |

| G 180-10 Pro | 10 | 145 | 516.6 | 31 | 1095 | 180 | 241 | ANSI 4″ | 4213 | 9288 |

| G 180-14 Pro | 14 | 203 | 416.7 | 25 | 883 | 180 | 241 | ANSI 4″ | 4213 | 9288 |

| G 200-7.5 Pro | 7.5 | 109 | 680.1 | 40.8 | 1441 | 200 | 268 | ANSI 4″ | 4298 | 9475 |

| G 200-8.5 Pro | 8.5 | 123 | 668.3 | 40.1 | 1416 | 200 | 268 | ANSI 4″ | 4298 | 9475 |

| G 200-10 Pro | 10 | 145 | 596.7 | 35.8 | 1264 | 200 | 268 | ANSI 4″ | 4298 | 9475 |

| G 200-14 Pro | 14 | 203 | 495.1 | 29.7 | 1049 | 200 | 268 | ANSI 4″ | 4298 | 9475 |

| G 250-7.5 Pro | 7.5 | 109 | 741.7 | 44.5 | 1572 | 250 | 335 | ANSI 4″ | 4513 | 9949 |

| G 250-8.5 Pro | 8.5 | 123 | 741.6 | 44.5 | 1571 | 250 | 335 | ANSI 4″ | 4513 | 9949 |

| G 250-10 Pro | 10 | 145 | 683.3 | 41 | 1448 | 250 | 335 | ANSI 4″ | 4513 | 9949 |

| G 250-14 Pro | 14 | 203 | 570 | 34.2 | 1208 | 250 | 335 | ANSI 4″ | 4513 | 9949 |

| G 250L-7.5 Pro | 7.5 | 109 | 890 | 53.4 | 1886 | 250 | 335 | ANSI 5″ | 6760 | 14903 |

| G 250L-8.5 Pro | 8.5 | 123 | 843 | 50.6 | 1785 | 250 | 335 | ANSI 5″ | 6760 | 14903 |

| G 250L-10 Pro | 10 | 145 | 780 | 46.8 | 1652 | 250 | 335 | ANSI 5″ | 6760 | 14903 |

| G 250L-14 Pro | 14 | 203 | 705 | 42.3 | 1494 | 250 | 335 | ANSI 5″ | 6760 | 14903 |

| G 315-7.5 Pro | 7.5 | 109 | 1046 | 62.8 | 2217 | 315 | 422 | ANSI 5″ | 6790 | 14969 |

| G 315-8.5 Pro | 8.5 | 123 | 1006 | 60.4 | 2131 | 315 | 422 | ANSI 5″ | 6790 | 14969 |

| G 315-10 Pro | 10 | 145 | 910 | 54.6 | 1928 | 315 | 422 | ANSI 5″ | 6790 | 14969 |

| G 315-14 Pro | 14 | 203 | 777 | 46.6 | 1646 | 315 | 422 | ANSI 5″ | 6790 | 14969 |

| *G 355-7.5 Pro | 7.5 | 109 | 1093 | 65.6 | 2316 | 355 | 476 | ANSI 5″ | 7130 | 15719 |

| G 355-8.5 Pro | 8.5 | 123 | 1084 | 65.1 | 2297 | 355 | 476 | ANSI 5″ | 7130 | 15719 |

| G 355-10 Pro | 10 | 145 | 1004 | 60.3 | 2128 | 355 | 476 | ANSI 5″ | 7130 | 15719 |

| G 355-14 Pro | 14 | 203 | 854 | 51.2 | 1809 | 355 | 476 | ANSI 5″ | 7130 | 15719 |

* G 355-7.5 Pro FAD is 1140 l/s for water cooled version

(1) Unit performance : Measured according to ISO1217 Reference conditions:

– Absolute inlet pressure 1 bar (14,5psi)

– Intake air temperature 20°C (68°F)

– Cooling medium temperature 20°C (68°F)

FAD is measured at the following working pressures:

• 7.5 bar variants at 7 bar

• 8.5 bar variants at 8 bar

• 10 bar variants at 10 bar

• 14 bar variants at 12.5 bar

Technical Data 60 Hz VSD

| TYPE | Maximum working pressure | Capacity FAD (1) | Installed motor power | Air Outlet Size | Weight (shipping mass) | |||||

| Standard | Pack | Standard | ||||||||

| bar(e) | psig | l/s | m3/min | cfm | kW | HP | KG | lbs | ||

| 60 Hz | ||||||||||

| G 110 VSD – 10 | Minimum | 4 | 58 | 81-335 | 4.9-20.1 | 172-710 | 110 | 150 | NPT 2-1/2” | 2100 4630 |

| G 110 VSD – 10 | 7 | 102 | 77-335 | 4.6-20.1 | 163-710 | 110 | 150 | NPT 2-1/2” | 2100 4630 | |

| G 110 VSD – 10 | 8 | 116 | 76-313 | 4.6-18.8 | 161-664 | 110 | 150 | NPT 2-1/2” | 2100 4630 | |

| G 110 VSD – 10 | Maximum | 10 | 138 | 76-290 | 4.5-17.4 | 160-614 | 110 | 150 | NPT 2-1/2” | 2100 4630 |

| G 110 VSD – 14 | Maximum | 14 | 203 | 83-244 | 5-14.6 | 176-518 | 110 | 150 | NPT 2-1/2” | 2100 4630 |

| G 132 VSD – 10 | Minimum | 4 | 58 | 114-399 | 6.8-23.9 | 241-845 | 132 | 175 | NPT 2-1/2” | 2200 4850 |

| G 132 VSD – 10 | 7 | 102 | 109-399 | 6.6-23.9 | 231-844 | 132 | 175 | NPT 2-1/2” | 2200 4850 | |

| G 132 VSD – 10 | 8 | 116 | 108-383 | 6.5-23 | 230-811 | 132 | 175 | NPT 2-1/2” | 2200 4850 | |

| G 132 VSD – 10 | Maximum | 10 | 138 | 108-347 | 6.5-20.8 | 229-736 | 132 | 175 | NPT 2-1/2” | 2200 4850 |

| G 132 VSD – 14 | Maximum | 14 | 203 | 112-288 | 8.7-17.3 | 238-611 | 132 | 175 | NPT 2-1/2” | 2200 4850 |

| G 160VSD-10 Pro | 10 | 145 | 201.9-543.3 | 12.1-32.6 | 428-1151 | 160 | 215 | ANSI 4″ | 3570 7871 | |

| G 160VSD-14 Pro | 14 | 203 | 202.3-461.6 | 12.1-27.7 | 429-978 | 160 | 215 | ANSI 4″ | 3570 7871 | |

| G 180VSD-10 Pro | 10 | 145 | 198.3-613.4 | 11.9-36.8 | 420-1300 | 180 | 241 | ANSI 4″ | 3607 7952 | |

| G 180VSD-14 Pro | 14 | 203 | 199.6-516.6 | 12.0-31.0 | 423-1095 | 180 | 241 | ANSI 4″ | 3607 7952 | |

| G 200VSD-10 Pro | 10 | 145 | 198.4-706.7 | 11.9-42.4 | 420-1497 | 200 | 268 | ANSI 4″ | 3617 7974 | |

| G 200VSD-14 Pro | 14 | 203 | 254.1-600 | 15.2-36.0 | 538-1271 | 200 | 268 | ANSI 4″ | 3617 7974 | |

| G 250VSD-10 Pro | 10 | 145 | 198.5-750 | 11.9-45.0 | 421-1589 | 250 | 335 | ANSI 4″ | 3792 8360 | |

| G 250VSD-14 Pro | 14 | 203 | 200.4-651.7 | 12.0-39.1 | 425-1381 | 250 | 335 | ANSI 4″ | 3792 8360 | |

| G 250LVSD-10 Pro | 10 | 145 | 277-883 | 16.6-53.0 | 587-1872 | 250 | 335 | ANSI 5″ | 6495 14319 | |

| G 250LVSD-14 Pro | 14 | 203 | 267-750 | 16.0-45.0 | 566-1589 | 250 | 335 | ANSI 5″ | 6495 14319 | |

| G 315VSD-10 Pro | 10 | 145 | 352-1050 | 21.1-63.0 | 746-2225 | 315 | 422 | ANSI 5″ | 6740 14859 | |

| G 315VSD-14 Pro | 14 | 203 | 345-939 | 20.7-56.3 | 731-1989 | 315 | 422 | ANSI 5″ | 6740 14859 | |

| *G 355VSD-10 Pro | 10 | 145 | 351-1090 | 21.1-65.4 | 744-2310 | 355 | 476 | ANSI 5″ | 6750 14881 | |

| G 355VSD-14 Pro | 14 | 203 | 345-1020 | 20.7-61.2 | 731-2162 | 355 | 476 | ANSI 5″ | 6750 14881 | |

* G 355VSD-10 Pro max FAD is up to 1140 l/s for water cooled version

(1) Unit performance : Measured according to ISO1217

Reference conditions:

– Absolute inlet pressure 1 bar (14,5psi)

– Intake air temperature 20°C (68°F)

– Cooling medium temperature 20°C (68°F)

FAD is measured at the following working pressures:

• 10 bar variants between 7 to 10 bar

• 14 bar variants between 10 to 14 bar

Atlas Copco G 90-355 (VSD) Air Compressors FAQ

1.What is VSD technology, and how does it benefit energy consumption?

VSD adjusts the compressor’s speed based on demand, reducing energy consumption by up to 35%.

2.Can the G 90-355 (VSD) compressors handle varying air demand?

Yes, the VSD technology ensures precise air delivery based on varying load requirements.

3.What maintenance is required for the G 90-355 (VSD) series?

Routine maintenance is minimal, with easy access for oil changes and air filters.

4.What are the space-saving features of these compressors?

The compact design allows installation in tight spaces, optimizing floor area.

5.How does the Elektronikon® MK5 control system optimize compressor performance?

It provides intelligent monitoring, automates performance adjustments, and enhances operational efficiency.

The Atlas Copco G 90-355 (VSD) air compressors stand out as the ultimate solution for businesses seeking a blend of efficiency, reliability, and cost savings. With their advanced Variable Speed Drive (VSD) technology, these compressors dynamically adjust to meet fluctuating air demands, delivering precise performance and significantly reducing energy consumption. Their robust design ensures long-lasting durability and minimal downtime, while the user-friendly maintenance features keep operating costs low. Whether you’re looking to enhance productivity or cut energy costs, the G 90-355 (VSD) series offers unparalleled value for industries ranging from manufacturing to construction.

Ready to experience the benefits of cutting-edge air compression technology? Contact us today to learn more about the Atlas Copco G 90-355 (VSD) series air compressors and find the perfect solution tailored to your needs. Our team of experts is here to assist you with customized solutions and provide detailed product information. Don’t wait—optimize your operations today!

Download the Atlas Copco G90-355 (VSD) Air Compressors product brochure:Atlas Copco G90-355 (VSD) Compressors Leaflet EN Wuxi 6996104301

Anonymous_Buyer –

This model runs quietly and efficiently!

Atlas Copco has truly set the standard for air compressors. This model runs quietly and efficiently, providing all the power we need for our workshop without unnecessary energy waste. What really impressed me was the attention to detail in its design—it’s sturdy, well-built, and easy to maintain. The controls are intuitive, making it simple for our staff to operate. Customer service was also fantastic, guiding us through the selection process to ensure we got the right unit for our needs. This compressor has been a game-changer for our business, and we couldn’t be happier with it.

*L Randall –

Low noise, energy-efficient, and easy to maintain.

We’ve been using the Atlas Copco G90 air compressor purchased from Seadweer for over 3 months—super reliable with excellent performance. Low noise, energy-efficient, and easy to maintain. Great choice for continuous industrial use.