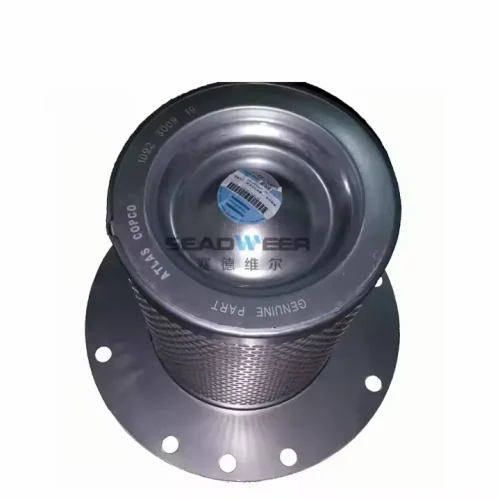

Maintaining the integrity and efficiency of your air compressor is paramount for any industrial operation. Consequently, selecting the right components, especially critical filtration elements like the oil filter, directly impacts your system’s longevity and performance. The Atlas Copco Compressor 1202804093=1202804003 Oil Filter stand as a testament to unparalleled quality and reliability. Sourced from a trusted Atlas Copco professional supplier, Seadweer, this genuine filter guarantees optimal protection and sustained operational excellence for your valuable equipment.

Contents

The Undeniable Advantages of a Genuine Atlas Copco Oil Filter

A genuine Atlas Copco oil filter is not merely a replacement part; it is a meticulously engineered component. It seamlessly integrates into your compressor system, ensuring peak performance and extended service life. Therefore, investing in this authentic filter safeguards your equipment and optimizes your operational costs over time.

Superior Filtration Efficiency for Pristine Oil Quality

Firstly, this Atlas Copco oil filter excels at removing contaminants from your compressor’s lubricating oil. It precisely traps and eliminates particulate matter, including dirt, dust, and microscopic metal shavings. This ensures your oil remains exceptionally clean. Consequently, it prevents harmful abrasive particles from circulating within the system, protecting vital components. Advanced synthetic filter paper, resistant to temperature fluctuations and various compressor oils, ensures high performance. It boasts a high dirt-holding capacity, significantly extending service intervals.

Enhanced Protection and Extended Equipment Lifespan

Secondly, cleaner air compressor oil dramatically reduces wear and tear on crucial internal components, such as bearings, pistons, and cylinders. By effectively removing contaminants, the filter prevents premature abrasion and damage. This robust protection directly translates into a significantly extended lifespan for your air compressor. Ultimately, it reduces the frequency of costly maintenance and repairs. Your investment remains protected for longer.

Optimized System Performance and Energy Efficiency

Furthermore, maintaining clean air compressor oil is vital for the overall efficiency and performance of your air compressor. This filter preserves the oil’s lubricating properties, facilitating smooth operation and minimizing friction within moving parts. An optimally performing compressor results in higher productivity and potentially lower energy consumption. Therefore, choosing a genuine Atlas Copco filter helps maintain the original factory specifications for unparalleled system reliability.

Product Technical Parameters

Understanding the technical specifications of the Atlas Copco 1202804093=1202804003 Oil Filter highlights its robust design and superior engineering.

| Parameter | Value |

| Part Number(s) | 1202804093, 1202804003 |

| Type | Compressor Oil Filter |

| Filtration Accuracy | Typically 10µm – 15µm |

| Initial Pressure Difference | ≤ 0.03 MPa (0.43 PSI) |

| Maximum Working Pressure | 1.4 MPa – 2.5 MPa (203-363 PSI) |

| Filter Media | High-quality synthetic filter paper |

| Bypass Valve | Yes, integrated |

| Expected Service Life | Generally recommended replacement after 2000 hours of use (or as per compressor manual) |

Product information

| Specification | Value |

| Weight | 1004 g |

| Width | 100 mm |

| Height | 220 mm |

| Length | 100 mm |

Step-by-Step Installation Guide

Proper installation of your new oil filter is crucial for its effective performance and the longevity of your compressor. Always prioritize safety by following your compressor’s specific service manual.

Before You Begin:

- Safety First: Ensure the compressor is shut down, depressurized, and locked out/tagged out to prevent accidental startup. Allow the compressor to cool down if it has been running.

- Gather Tools: You will typically need an oil filter wrench, a drain pan, rags, and new compressor oil (if performing an oil change simultaneously).

- Prepare the Area: Place the drain pan beneath the oil filter housing to catch any dripping oil.

Installation Steps:

- Drain Old Oil (Optional but Recommended): If you are performing a full oil change, locate and open the oil drain valve to drain the old compressor oil into the pan.

- Remove Old Filter: Use an oil filter wrench to loosen the old oil filter. Once loose, carefully unscrew it by hand. Be prepared for some residual oil to spill.

- Inspect and Clean: Thoroughly clean the oil filter mounting surface on the compressor. Inspect for any old gasket material or debris and remove it. A clean surface ensures a proper seal.

- Prepare New Filter: Apply a thin film of new compressor oil to the rubber gasket of the new Atlas Copco oil filter. This lubrication helps create a good seal and prevents the gasket from twisting during installation.

- Install New Filter: Carefully screw the new filter onto the mounting stud by hand. Once the gasket makes contact with the mounting surface, tighten it according to the manufacturer’s specifications, usually 3/4 to 1 full turn past hand-tight, or as indicated on the filter itself. Do not overtighten, as this can damage the filter or its seal.

- Refill Oil (If Drained): If you drained the oil, refill the compressor with the recommended quantity and type of genuine Atlas Copco compressor oil. Check the oil level using the dipstick or sight glass.

- Run and Check for Leaks: Start the compressor and allow it to run for a few minutes. Carefully inspect the new oil filter and its seal for any signs of leaks. If leaks are present, shut down the compressor immediately and re-tighten the filter slightly, or re-check the installation.

- Final Oil Level Check: After the compressor has run and then settled for a few minutes, re-check the oil level and add more if necessary to reach the proper operating range.

- Dispose Responsibly: Properly dispose of the old oil filter and used oil according to local environmental regulations.

User Experience

“As a facility manager overseeing several Atlas Copco air compressors, the consistent performance of our equipment is non-negotiable. We strictly use genuine Atlas Copco parts, and the 1202804093 oil filter is a prime example of why. Recently, during a routine service, our technician noted how remarkably clean the compressor oil remained, even approaching the scheduled replacement interval. This filter truly does an excellent job of capturing contaminants.

We’ve experienced fewer unexpected shutdowns and significantly reduced wear on our compressor components since standardizing on these genuine filters. They install smoothly, and we never have concerns about fit or sealing issues. This translates directly into predictable maintenance schedules and, more importantly, uninterrupted production. The slight premium for genuine parts is a small price to pay for the peace of mind and the long-term reliability they deliver. Our compressors consistently operate at peak efficiency, and that’s largely due to the quality of components like this oil filter.”

– John M., Facility Manager, Industrial Manufacturing

Frequently Asked Questions (FAQs)

1. Why is it important to use a genuine Atlas Copco oil filter?

Using a genuine Atlas Copco oil filter ensures optimal performance, extends the lifespan of your compressor, and maintains your warranty. Genuine filters are designed and tested to meet the exact specifications of your Atlas Copco machine, offering superior filtration and reliable operation.

2. How often should I replace my Atlas Copco 1202804093 oil filter?

It is generally recommended to replace the filter every 2000 hours of operation or as specified in your compressor’s maintenance manual. Regular replacement is crucial to maintain oil cleanliness and prevent damage to internal components.

3. Can a clogged oil filter damage my air compressor?

Absolutely. A clogged oil filter can restrict oil flow, leading to insufficient lubrication (oil starvation) of critical components. This can cause increased friction, overheating, premature wear, and even catastrophic failure of the compressor element.

4. What are the key technical parameters of this oil filter?

Key parameters include a filtration accuracy of 10µm – 15µm, an initial pressure difference of ≤ 0.03 MPa, and a maximum working pressure of 1.4 MPa – 2.5 MPa. It also features high-quality synthetic filter paper and an integrated bypass valve.

5. Where can I purchase genuine Atlas Copco oil filters like the 1202804093?

You can purchase from genuine Atlas Copco air compressor parts distributor and professional suppliers like Seadweer. These suppliers ensure you receive authentic parts, providing peace of mind and maintaining the integrity of your Atlas Copco equipment.

More Oil Filters List

If you need other Atlas Copco air compressor oil filters, we provide more models in the table below or you can submit your requirements to us directly.

| Part Number | Part Name | Part-Number |

| 1627410122 | Oil filter | 1627-4101-22 |

| 1627410137 | OIL FILTER | 1627-4101-37 |

| 1627411000 | OIL FILTER | 1627-4110-00 |

| 1630686750 | OIL FILTER | 1630-6867-50 |

| 1625106356 | Oil filter | 1625-1063-56 |

| 1625106475 | Oil filter | 1625-1064-75 |

| 1625106576 | Oil filter | 1625-1065-76 |

| 1625165600 | OIL FILTER | 1625-1656-00 |

| 1625165601 | OIL FILTER | 1625-1656-01 |

| 1625165602 | OIL FILTER | 1625-1656-02 |

| 1625165603 | OIL FILTER | 1625-1656-03 |

| 1625165612 | OIL FILTER | 1625-1656-12 |

| 1625165613 | OIL FILTER | 1625-1656-13 |

| 1625165615 | OIL FILTER | 1625-1656-15 |

| 1625165616 | OIL FILTER | 1625-1656-16 |

| 1625165620 | OIL FILTER | 1625-1656-20 |

| 1625165621 | OIL FILTER | 1625-1656-21 |

| 1625165622 | OIL FILTER | 1625-1656-22 |

| 1625165624 | OIL FILTER | 1625-1656-24 |

| 1625165627 | Oil filter | 1625-1656-27 |

| 1625165628 | oil filter | 1625-1656-28 |

| 1625165629 | OIL FILTER | 1625-1656-29 |

| 1625165630 | OIL FILTER | 1625-1656-30 |

| 1625165631 | OIL FILTER | 1625-1656-31 |

| 1625165632 | OIL FILTER | 1625-1656-32 |

| 1625165639 | OIL FILTER | 1625-1656-39 |

| 1625165640 | OIL FILTER | 1625-1656-40 |

| 1625170487 | OIL FILTER | 1625-1704-87 |

| 1625173703 | Oil filter | 1625-1737-03 |

| 1625173704 | OIL FILTER | 1625-1737-04 |

| 1625185452 | OIL FILTER | 1625-1854-52 |

| 2205400006 | OIL FILTER | 2205-4000-06 |

| 2205431902 | OIL FILTER | 2205-4319-02 |

| 2205615644 | OIL FILTER | 2205-6156-44 |

| 2205722421 | OIL FILTER | 2205-7224-21 |

| 9095100901 | OIL FILTER | 9095-1009-01 |

| 9095100901 | OIL FILTER | 9095-1009-01 |

| 9095100701 | OIL FILTER | 9095-1007-01 |

| 9095100701 | OIL FILTER | 9095-1007-01 |

| 1621874900 | OIL FILTER | 1621-8749-00 |

| 1621884700 | OIL FILTER | 1621-8847-00 |

| 1614935200 | OIL FILTER | 1614-9352-00 |

| 1202849600 | OIL FILTER | 1202-8496-00 |

| 1202849600 | OIL FILTER | 1202-8496-00 |

| 1202849590 | OIL FILTER | 1202-8495-90 |

| 1202849590 | OIL FILTER | 1202-8495-90 |

| 1420091783 | OIL FILTER | 1420-0917-83 |

| 1504221076 | OIL FILTER | 1504-2210-76 |

| 1610143500 | OIL FILTER | 1610-1435-00 |

| 1513033701 | OIL FILTER | 1513-0337-01 |

Secure Your Investment Today

Safeguard your Atlas Copco compressor’s performance and longevity. Choose the genuine Atlas Copco Compressor Oil Filter 1202804093=1202804003. As an original genuine product offered by Seadweer, a trusted professional supplier, it promises unmatched quality and reliable protection. Don’t compromise on the health of your valuable machinery.

Contact Seadweer or your authorized Atlas Copco supplier today to place your order and ensure your operations run smoothly and efficiently for years to come!

John M –

This filter truly does an excellent job of capturing contaminants.

We strictly use genuine Atlas Copco parts, and the 1202804093 oil filter is a prime example of why. Recently, during a routine service, our technician noted how remarkably clean the compressor oil remained, even approaching the scheduled replacement interval. This filter truly does an excellent job of capturing contaminants.