Industrial air compressor maintenance demands precision, reliability, and authentic components. The Atlas Copco C190 Air End 2906097300 Overhaul Kit represents the pinnacle of engineering excellence for Atlas Copco air compressors. Furthermore, this comprehensive maintenance solution ensures optimal performance while extending equipment lifespan significantly.

Contents

Understanding the Atlas Copco C190 Air End System

The C190 air end serves as the heart of Atlas Copco’s industrial compression systems. Additionally, this critical component requires periodic overhaul to maintain peak efficiency. Professional technicians recognize that genuine overhaul kits prevent costly downtime while ensuring consistent compressed air quality.

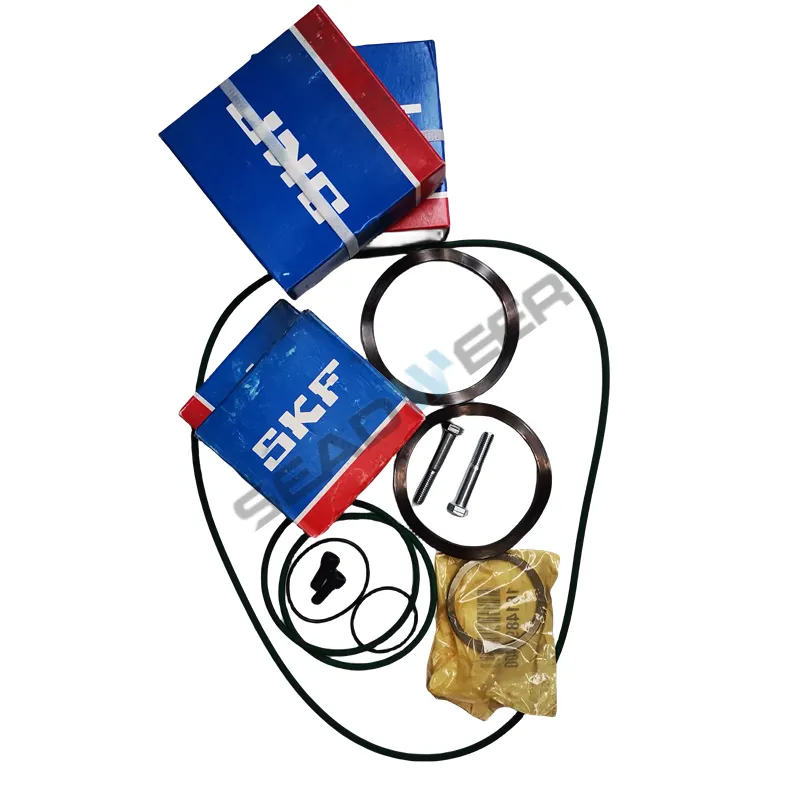

Seadweer, as an authorized Atlas Copco supplier, provides authentic overhaul kitsF that meet stringent manufacturing standards. Moreover, these genuine components undergo rigorous quality testing before reaching end users. The 2906097300 kit specifically addresses wear patterns common in C190 applications.

Genuine vs. Alternative Components

| Feature | Atlas Copco Genuine Kit | Alternative Parts |

| Material Quality | Premium grade alloys and seals | Variable quality materials |

| Manufacturing Tolerance | ± 0.01mm precision | ± 0.05mm or higher variance |

| Performance Guarantee | Full manufacturer warranty | Limited or no warranty |

| Lifespan | 8,000-10,000 operating hours | 3,000-5,000 operating hours |

| Compatibility | 100% exact fit guarantee | 85-95% compatibility rate |

| Technical Support | Complete documentation included | Basic installation guides only |

Professional Installation Procedure

Step 1: Pre-Installation Preparation

Initially, ensure the compressor system reaches complete shutdown status. Subsequently, drain all compressed air from the system and disconnect electrical power sources. Meanwhile, gather necessary tools including torque wrenches, seal pullers, and precision measuring instruments.

Step 2: Air End Removal

Carefully disconnect all pneumatic connections while maintaining proper labeling for reassembly. Then, remove the air end assembly from the compressor frame using appropriate lifting equipment. Additionally, clean the mounting surfaces thoroughly to prevent contamination during reassembly.

Step 3: Disassembly Process

Begin by removing the inlet valve assembly and separating the rotor housing components. Next, extract the male and female rotors using specialized pullers to avoid damage. Furthermore, inspect all surfaces for wear patterns or damage requiring additional attention.

Step 4: Component Replacement

Install new seals and gaskets according to the manufacturer’s torque specifications. Moreover, replace all bearings and ensure proper lubrication before assembly. The genuine kit includes detailed instructions specifying 25-30 Nm torque for critical fasteners.

Step 5: Reassembly and Testing

Reassemble components in reverse order while maintaining cleanliness throughout the process. Subsequently, perform leak testing at 50% operating pressure before full commissioning.Finally, conduct vibration analysis to confirm proper installation and balance.

Real User Experience

John Mitchell, Senior Maintenance Engineer at Global Manufacturing Solutions, shares his experience: “We’ve been using Atlas Copco genuine overhaul kits for our C190 units across three production facilities. The difference in reliability is remarkable compared to alternative components we tried previously.

After installing the 2906097300 overhaul kit on our primary GA132 compressor, we observed immediate improvements in operational efficiency. The noise levels decreased by approximately 20%, while energy consumption dropped by 8% during continuous operation. Most importantly, we haven’t experienced any unscheduled downtime in the eight months since installation.

The comprehensive documentation provided excellent guidance throughout the installation process. Our technicians particularly appreciated the clear torque specifications and step-by-step photographs. This attention to detail reflects Atlas Copco’s commitment to supporting maintenance professionals.”

Frequently Asked Questions

Q1: How often should the C190 air end undergo complete overhaul?

Typically, overhaul intervals range from 8,000 to 12,000 operating hours depending on application severity. However, harsh environments may require more frequent maintenance at 6,000-8,000 hour intervals.

Q2: Can I mix genuine and alternative components in the same overhaul?

While technically possible, mixing components compromises overall system reliability and voids manufacturer warranties. Therefore, complete genuine kit installation ensures optimal performance and full warranty coverage.

Q3: What tools are required for professional installation?

Essential tools include precision torque wrenches, bearing pullers, dial indicators, and pneumatic testing equipment. Additionally, specialized rotor handling tools prevent damage during disassembly and reassembly procedures.

Q4: How does ambient temperature affect overhaul kit performance?

Operating temperatures above 65°C significantly reduce seal life and bearing performance. Consequently, proper ventilation and cooling system maintenance become critical for extending overhaul intervals.

Q5: Are training resources available for technicians performing overhauls?

Atlas Copco provides comprehensive training programs through authorized distributors like Seadweer. Furthermore, detailed service manuals and video resources support technicians throughout the maintenance process.

Conclusion

The Atlas Copco C190 Air End 2906097300 Overhaul Kit represents essential maintenance investment for industrial compressed air systems. Through genuine components and professional installation, operators achieve maximum reliability while minimizing total cost of ownership. Seadweer’s expertise as an authorized supplier ensures access to authentic components backed by comprehensive technical support.

Anonymous –

This overhaul kit was a perfect fit for our C190 air end.

The quality of the components is excellent, and it had everything needed for a complete rebuild. Our compressor is running like new again. Highly recommend for its comprehensive nature and genuine parts.