The Atlas Copco AQ 15-55 VSD Oil-free water-injected compressors includes the AQ15VSD, AQ18VSD, AQ22VSD, AQ30VSD, AQ37VSD, AQ45VSD, and AQ55VSD models, offering a comprehensive range of oil-free compressed air solutions tailored to demanding applications. These state-of-the-art compressors are engineered to deliver superior quality, 100% oil-free compressed air, meeting the stringent requirements of industries where air purity is absolutely critical.

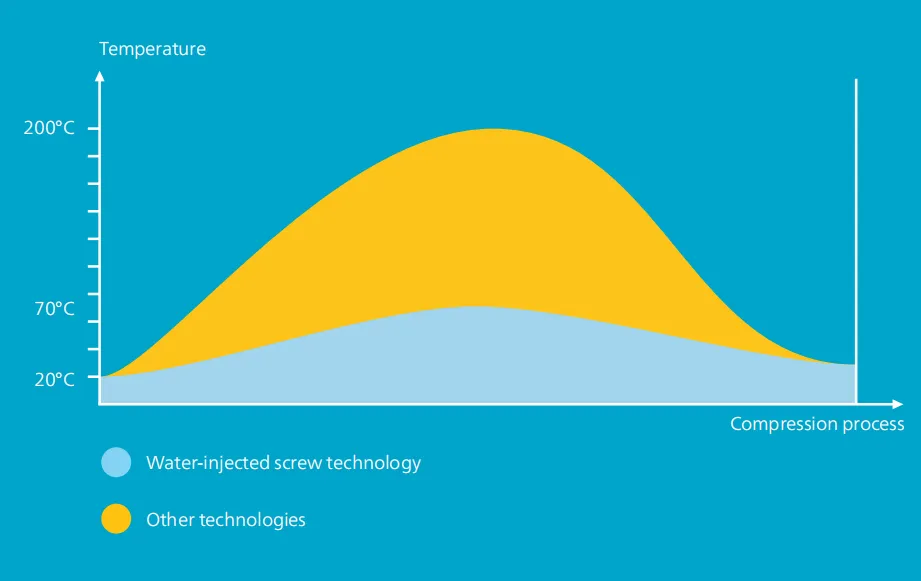

Atlas Copco’s AQ 15-55 VSD oil-free water-injected compressor solutions deliver uncompromising quality for industries that demand absolute purity. For decades, we’ve led the market with our innovative water-injected screw technology, offering a comprehensive range of compressors that guarantee 100% oil-free air.

Certified Purity & Maximum Efficiency

The AQ AQ 15-55 VSD Oil-free Water-Injected compressor meets the highest industry standards with ISO 8573-1 CLASS 0 certification, ensuring completely oil-free air while maintaining superior energy efficiency.

Zero Contamination Risk

In critical industries like pharmaceuticals, food & beverage, and electronics, air quality directly impacts product integrity and production processes. Atlas Copco’s AQ 15-55 VSD Oil-free Water-Injected compressor eliminate any risk of oil contamination, safeguarding your operations.

Lower Energy Consumption

With energy costs accounting for more than 70% of a compressor’s total lifecycle expenses, our solutions optimize efficiency to reduce operational costs.

Trust Atlas Copco for reliable, clean, and energy-efficient compressed air—where quality is non-negotiable.

Complete integration, compact footprint

- Minimal system pressure drop.

- Integrated refrigerant dryer.

- Reduced piping costs.

- Single point connections.

- Single point monitoring.

- Low-noise operation

• Pressure dewpoint of 3°C/38°F (100% relative humidity at 20°C/68°F).

• Heat exchanger cross-flow technology with low pressure drop.

• Zero waste of compressed air thanks to no-loss condensate drain.

• Reduced operating costs.

• Environmentally-friendly characteristics; zero ozone depletion.

• Global warming potential has been lowered significantly by an average of 50% by reducing the amount of refrigerant in the new dryer.

The integrated refrigerant air dryer of the AQ VSD gives you a pressure dewpoint as low as 3°C/38°F, which means it can be used for applications that require IS0 8573-1 Class 4 air quality.

| Quality classes |

Particle size | Maximum pressure dewpoint | Maximum oil content (droplets, aerosols, and vapor ppm) |

||

| microns | °C | °F | w/w | mg/m3 | |

| 0 | as specified | as specified | as specified | ||

| 1 | 0.1 | -70 | -94 | 0.008 | 0.01 |

| 2 | 1 | -40 | -40 | 0.08 | 0.1 |

| 3 | 5 | -20 | -4 | 0.8 | 1 |

| 4 | 15 | 3 | 38 | 4 | 5 |

| 5 | 40 | 7 | 45 | 21 | 25 |

| 6 | – | 10 | 50 | – | – |

* The table values reflect the maximum limits according to the ISO quality air standard (ISO 8573-1:2010).

** Water pressure dewpoint based on 100% RH at 20°C/68°F.

What is unique about the integrated Atlas Copco AQ VSD?

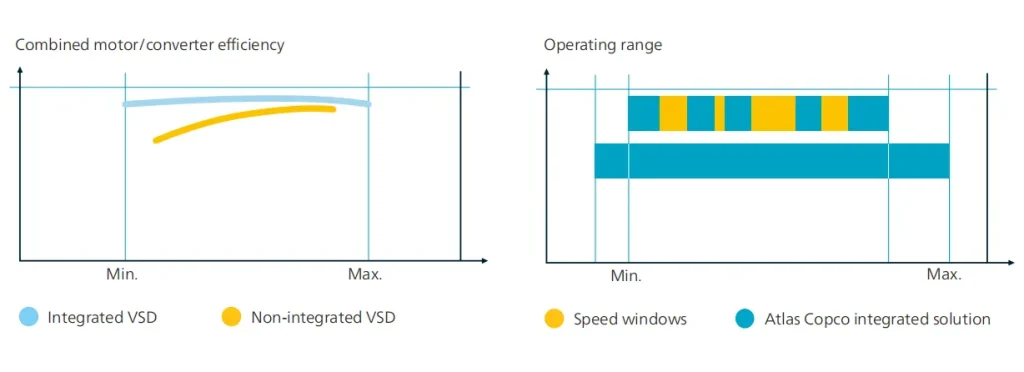

Equipped with Variable Speed Drive (VSD) technology, the AQ series automatically adjusts its motor speed to precisely match the fluctuating air demand in real-time. This intelligent operation results in significant energy savings, often reducing energy consumption by an average of 35% or more compared to fixed-speed compressors. By eliminating wasteful unloaded running periods and optimizing energy use, VSD technology directly translates into substantially lower operational costs and a reduced carbon footprint.

1.The Elektronikon controls both the compressor and the integrated converter, ensuring maximum machine safety within parameters.

2.Flexible pressure selection from 4 to 13 bar with electronic gearing reduces electricity cost

3.Electric motor specifcally designed for VSD operation (inverter duty motor). Bearings are protected against induced bearing currents. Both motor and converter are perfectly tuned for highest efciency across the entire speed range.

4.Electric motor specifcally designed for low operating speeds with clear attention to motor cooling and compressor cooling requirements.

5.All Atlas Copco AQ VSD compressors are EMC-tested and certifed. External sources do not infuence compressor operation, nor does the compressor afect the operation of other instruments via emissions or via the power supply line.

6.Mechanical enhancements ensure that all components operate below critical vibration levels throughout the entire compressor speed range.

7.A highly efcient frequency converter in a cool overpressure cubicle ensures stable operation.

8.No‘speed windows’that can jeopardize the energy savings and the stable net pressure. Turndown capability of the compressor is maximized

9.The cubicle cooling booster increases the lifetime of electrical components due to a cool cubicle in overpressure and reduced dust ingress.

10.Ofering precise control over pressure, a net pressure band is maintained within 0.10 bar, 1.5 psi.

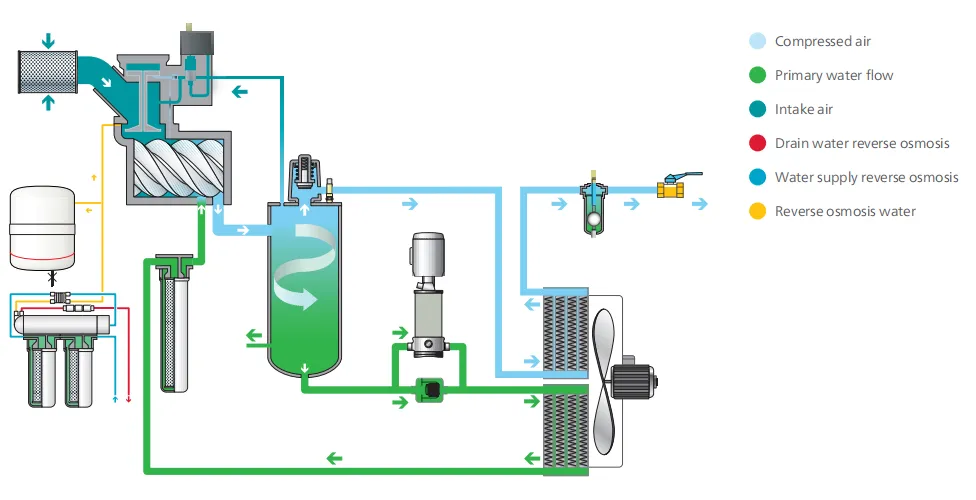

Flow diagram (air-cooled)

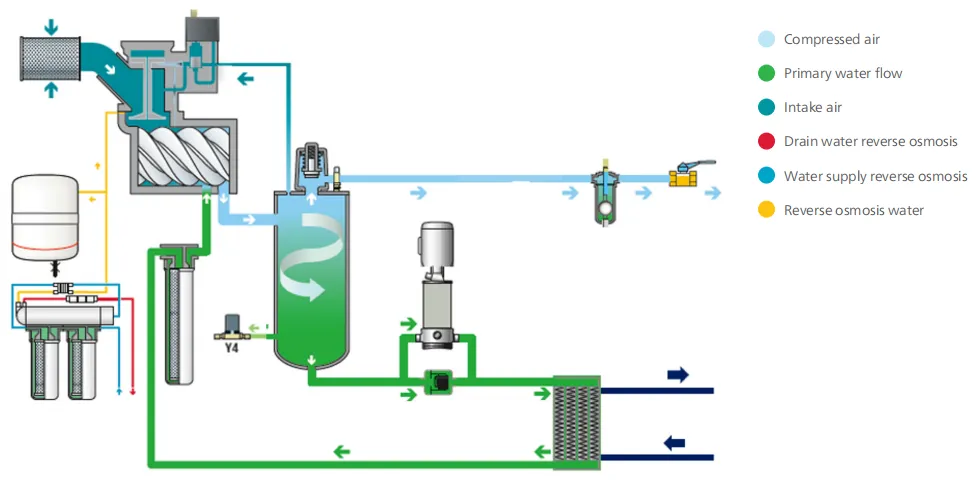

Flow diagram (water-cooled)

AQ 15-55 VSD Technical specifications

|

Compressor type |

Max. working pressure (bar(e)/psig) | Capacity FAD* | Installed motor power | Noise level** | Weight (kg/lbs) | |||||

| Pack | Full Feature |

l/s |

m3/min | cfm | kW | hp | dB(A) | Pack | Full Feature | |

| Air-cooled | ||||||||||

| AQ 15 VSD | 13/188 | 12.75/185 | 22-47 | 1.3-2.8 | 47-100 | 15 | 20 | 67 | 650/1433 | 700/1543 |

| AQ 18 VSD | 13/188 | 12.75/185 | 22-54 | 1.3-3.2 | 47-114 | 18 | 25 | 69 | 650/1433 | 700/1543 |

| AQ 22 VSD | 13/188 | 12.75/185 | 22-66 | 1.3-4.0 | 47-140 | 22 | 30 | 70 | 740/1631 | 800/1764 |

| AQ 30 VSD | 13/188 | 12.75/185 | 22-83 | 1.3-5.0 | 47-176 | 30 | 40 | 72 | 740/1631 | 810/1786 |

| AQ 37 VSD | 13/188 | 12.75/185 | 39-108 | 2.4-6.3 | 83-228 | 37 | 50 | 69 | 1300/2866 | 1410/3108 |

| AQ 45 VSD | 13/188 | 12.75/185 | 40-130 | 2.4-7.6 | 86-275 | 45 | 60 | 72 | 1300/2866 | 1410/3108 |

| AQ 55 VSD | 13/188 | 12.75/185 | 40-155 | 2.4-9.1 | 86-329 | 55 | 75 | 75 | 1300/2866 | 1410/3108 |

| Water-cooled | ||||||||||

| AQ 15 VSD | 13/188 | 12.75/185 | 22-47 | 1.3-2.8 | 47-100 | 15 | 20 | 67 | 542/1195 | 592/1305 |

| AQ 18 VSD | 13/188 | 12.75/185 | 22-54 | 1.3-3.2 | 47-114 | 18 | 25 | 69 | 542/1195 | 592/1305 |

| AQ 22 VSD | 13/188 | 12.75/185 | 22-66 | 1.3-4.0 | 47-140 | 22 | 30 | 70 | 632/1393 | 692/1526 |

| AQ 30 VSD | 13/188 | 12.75/185 | 22-83 | 1.3-5.0 | 47-176 | 30 | 40 | 72 | 632/1393 | 702/1548 |

| AQ 37 VSD | 13/188 | 12.75/185 | 42-113 | 2.5-6.6 | 89-239 | 37 | 50 | 66 | 1186/2614 | 1296/2857 |

| AQ 45 VSD | 13/188 | 12.75/185 | 42-135 | 2.5-7.9 | 89-286 | 45 | 60 | 69 | 1186/2614 | 1296/2857 |

| AQ 55 VSD | 13/188 | 12.75/185 | 42-160 | 2.5-9.5 | 89-339 | 55 | 75 | 72 | 1186/2614 | 1296/2857 |

(1) Unit performance measured according to ISO 1217 Annex E, Edition 4, 2009.

(2) Mean sound pressure level according to ISO 2151, uncertainty 3 dB(A).

AQ 15-55 VSD Dimensions

|

Dimensions |

Air-cooled | Water-cooled | ||||

| L (mm) | W (mm) | H (mm) | L (mm) | W (mm) | H (mm) | |

| AQ 15-30 VSD | 1976 | 974 | 1500 | 1976 | 974 | 1500 |

| AQ 37-55 VSD | 2440 | 970 | 1830 | 2440 | 970 | 1830 |

Ready to elevate your production with guaranteed oil-free air and remarkable energy savings? The Atlas Copco AQ 15-55 VSD water-injected screw compressor series is your solution for uncompromising air purity and efficiency. Stop worrying about oil contamination and high energy bills. Invest in the proven performance and reliability of the AQ VSD range. Choose the model that perfectly matches your needs and experience lower operational costs, enhanced product quality, and complete peace of mind. Contact authorized Atlas Copco supplier — seadweer today for a personalized quote and discover how the AQ 15-55 VSD can power your critical processes with exceptional quality and efficiency.

Anonymous –

This model runs quietly and efficiently!

The compressor provides a steady and powerful airflow, ensuring that all our pneumatic tools work at their best. Unlike other compressors we’ve tried, this one doesn’t overheat, even after hours of continuous use. It’s also incredibly energy-efficient, which has helped reduce our operational costs. The customer service was excellent, answering all our questions and ensuring we chose the right model for our needs. We are very happy with this purchase and would recommend it to any industrial business.