The SF and SF+ ranges (SF8+ SF11+ SF15+ SF17+ SF22+) of oil-free scroll air compressors unite Atlas Copco’s vast experience and knowledge in a class-leading package. Whereas the SF range includes a standard pneumatic controller, the SF+ range boasts the high-end Elektronikon® controller. Reliable and compact, they both answer your demands through innovative technologies and supreme energy efficiency without compromising on quality.

Air compression is achieved by the interaction of a fixed and orbiting scroll. Air at inlet pressure enters the compression chamber at the exterior side of the scroll element. Once air is drawn in, the orbiting scroll seals off the inlet port.As the scroll continues to orbit, the air is progressively compressed into an increasingly smaller ‘pocket’. A continuous flow of compressed air leaves the scroll element through a discharge port in the center of the fixed scroll. This process is continuously repeated, resulting in the delivery of pulse-free compressed air.

Contents

COST-EFFICIENT,HIGH-QUALITY AIR

With a comprehensive suite of state-of-the-art oil-free compressor technologies like screw, tooth, centrifugal, reciprocating, and scroll, Atlas Copco offers optimal solutions for your specific needs. As many manufacturing processes depend on oil-free compressed air, we ensure its constant availability by stopping oil from entering your compressed air system.

PURE OIL-FREE AIR

The absence of metal-to-metal contact between the compression scrolls eliminates the need for oil lubrication within the compression chamber. This inherent design of the scroll compression principle guarantees the delivery of high-quality, oil-free air. Consequently, the SF compressor is entirely oil-free in every aspect of its operation.

ENERGY EFFICIENCY

Equipped as standard with IE3 Premium efficiency motors, the SF scroll compressors are ideally suited for sensitive applications demanding both flexibility and energy efficiency. Unloaded power consumption is effectively eliminated through the use of a straightforward start/stop control system. The advanced scroll technology further ensures optimal free air delivery, particularly benefiting low duty cycle applications.

EXTREMELY LOW NOISE LEVEL

Thanks to the slow operating speed of the scroll compression elements, SF scroll compressors (SF8+ SF11+ SF15+ SF17+ SF22+) are remarkably quiet. Sound levels can be as low as 53 dB(a), making the SF an excellent choice for installation in noise-sensitive working environments.

SIMPLICITY AND RELIABILITY

SF scroll compressors are synonymous with simplicity and reliability. Featuring a minimal number of moving parts, the compressor design ensures a long operational lifespan and requires limited service interventions. With their integrated design, Atlas Copco’s SF scroll compressors boast a minimal footprint and facilitate easy maintenance access.

PROVEN PEACE OF MIND

Atlas Copco has been a leader in oil-free compressed air technology for over sixty years, building upon extensive experience and continuous technological advancement. You can always have confidence in the product: stringent certification and testing procedures are conducted to guarantee that the air supplied meets the highest standards of quality control.

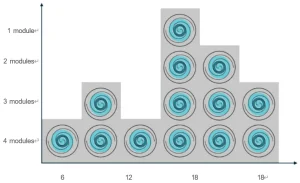

SF+ 8-22: MODULAR & FLEXIBLE

The SF8+ SF11+ SF15+ SF17+ SF22+ Atlas Copco scroll compressors delivers the advantages and flexibility of a modular system, incorporating between two and four compressor modules within a single canopy. The integrated Elektronikon® system constantly monitors the status of each individual element, automatically starting and stopping the compression modules as needed. This dynamic control ensures that the compressed air output precisely matches the current air demand. Furthermore, the excellent air quality and ease of use provided by these units contribute significantly to a superior production process.

①Air inlet filter

High efficiency paper cartridge inlet air filter, eliminating dust and particles down to 1 µm.

②IP55 Class F IE3 motor

Totally enclosed & air-cooled IP55 Class F motors, complying with IE3 Premium efficiency standards.

③High efficiency scroll element

Air-cooled scroll compressor elements with 8 and 10 bar variants, offering proven durability and reliability in operation, in addition to superior efficiency.

④Refrigerant dryer

Compact & optimized integrated refrigerant dryer ensuring the delivery of dry air, preventing rust and corrosion in the installed compressed air network.

⑤Silent canopy

Thanks to the low-noise scroll element, optimized super-silent fan and sound-insulated canopy, best in class noise levels possible are achieved.

⑥Elektronikon Mk5 Graphic

While running the VFT algorithm, the Elektronikon? Mk5 Graphic matches the required air demand, eliminating unload power consumption.

⑦Optimized cooler & piping

The air cooler is finetuned for improved performance, while the use of aluminum & stainless steel pipes improve reliability over lifetime and assure the high quality of compressed air.

⑧Smart design

Outstanding user-friendly design, with safety in operation & ease of serviceability in mind.

ADVANCED SCROLL TECHNOLOGY

Air compression is accomplished through the interaction between a stationary scroll and one that orbits. Air at the incoming pressure enters the compression chamber on the outer edge of the scroll element. Once the air has been drawn in, the orbiting scroll effectively seals off the inlet opening.

As the orbiting motion persists, the volume of air is progressively reduced within a shrinking ‘pocket’, causing it to be compressed. A steady stream of compressed air then exits the scroll element via a discharge port situated in the middle of the fixed scroll. This entire cycle is repeated continuously, resulting in the delivery of compressed air that is free from pulses.

- Cooling fan

- Suction chamber

- Suction opening

- Delivery opening

- Fixed scroll

- Orbiting scroll

- Fail-safe temperature sensor for unit protection

- Compression chamber

Variable flow technology (VFT)

All SF+ 8-22 multi-scroll compressors are equipped with the unique VFT control system. The VFT system, included in the Elektronikon® controller, automatically starts and stops the scroll elements to exactly match the demands of your compressed air system. The Elektronikon control algorithm ensures that the system pressure is kept within a very narrow pressure band.

WorkPlace Air System™ compressors: the sound of silence

The compressor operates at a low noise level, so users can install it close to the point of air use. This setup minimizes the size of the air distribution system, reduces pressure loss, and lowers the risk of leakage. Since the air treatment components are fully integrated, users also benefit from significantly lower installation costs, making it practical and cost-effective to install multiple compressors. To ensure maximum energy efficiency, Atlas Copco offers both traditional on/off regulating systems where the air demand is constant.

Variable flow technology (VFT)

CLASS ZERO: THE INDUSTRY STANDARD

Oil-free air is used in all kinds of industries where air quality is paramount. These applications include food and beverage processing, pharmaceutical manufacturing, petrochemical processing, wastewater treatment, and many more. In these critical environments, contamination by even the smallest quantities of oil can result in costly production downtime and product spoilage.

First in oil-free air technology

Over the past 60 years Atlas Copco has pioneered the development of oil-free air technology, resulting in a range of air compressors that provide 100% pure, oil-free air.Through continuous research and development, Atlas Copco achieved a new milestone, setting the standard for air purity as the first manufacturer to be awarded ISO 8573-1 Class 0 certification. Click here to know what is the ISO 8573.1 – Standards for contaminants and purity levels.

Eliminating any risk

As industry leader committed to meeting the needs of the most demanding customers, Atlas Copco requested the renownedTÜV institute to type-test its range of oil-free compressors. Using the most rigorous testing methodologies available, all possible oil forms were measured across a range of temperatures and pressures. The TÜV found no traces of oil at all in the output air stream. Thus Atlas Copco is the first compressor manufacturer to receive Class 0 certification, according to ISO 8573-1 Class 0 Ed. 3 2010 specifications.

| CLASS | Concentration total oil (aerosol, liquid, vapor) mg/m3 |

| 0 | As specified by the equipment user or supplier and more stringent than class 1 |

| 1 | < 0.01 |

| 2 | < 0.1 |

| 3 | < 1 |

| 4 | < 5 |

Controls and online monitoring

The next-generation Elektronikon operating system offers a wide variety of control and monitoring features that allow you to increase your compressor’s efficiency and reliability. To maximize energy efficiency, the Elektronikon® controls the main drive motor and regulates system pressure within a predefined and narrow pressure band. The SF4 are equipped with a standard Elektronikon® controller, while the SF8+ SF11+ SF15+ SF17+ SF22+ air compressors come with the advanced Elektronikon® Graphic.

Improved user-friendliness

• 3.5-inch high-definition color display with clear pictograms and extra 4th LED indicator for service.

• Graphical display of key parameters (day, week, month) and 32 language settings.

• Internet-based compressor visualization using a simple Ethernet connection.

• Graphical indication Serviceplan, remote control and connectivity functions.

• Software upgrade available to control up to 6 compressors by installing the optional integrated compressor controller.

FAQs

Here are the five FAQs translated into English for the Atlas Copco SF8-22+ oil-free scroll air compressor series:

1. Is the SF8-22+ series truly oil-free?

Yes, the SF8-22+ series uses oil-free scroll compression technology. There is no metal-to-metal contact inside the compression chamber, and no lubrication oil is needed. This ensures the delivery of 100% oil-free compressed air, certified to ISO 8573-1 CLASS 0, making it ideal for industries that demand the highest air purity, such as food processing, pharmaceuticals, and electronics.

2. How noisy is the SF8-22+ compressor? Is it suitable for offices or labs?

The SF8-22+ series operates very quietly. Thanks to its low-speed scroll elements and sound-insulated canopy, noise levels are as low as 53 dB(A). This makes it well-suited for noise-sensitive environments such as offices, laboratories, and medical facilities.

3. What are the benefits of the modular design in SF+ 8-22 models?

The SF+ 8-22 models feature a modular setup that integrates 2 to 4 compression modules within a single enclosure. With the Elektronikon® controller and Variable Flow Technology (VFT), the system automatically starts or stops modules based on real-time air demand. This ensures precise air delivery, maximizes energy efficiency, and extends the life of the equipment.

4. Is the SF8-22+ series easy to maintain?

Yes, the SF8-22+ compressors are designed with simplicity in mind. With few moving parts and a vertical layout, they are less prone to wear and easier to access for routine maintenance. This results in lower maintenance costs and improved operational reliability.

5. What installation options are available for the SF8-22+ series?

The SF8-22+ series offers multiple installation configurations, including:

- Standard: For users with existing air systems.

- Full Feature: Includes an integrated refrigerated dryer for dry, high-quality air.

- Tank-Mounted: Available with 30L, 270L, or 500L air receivers to suit different capacity needs.

- These flexible options allow users to choose the setup that best matches their application while minimizing installation costs and optimizing performance.

TECHNICAL SPECIFICATIONS

** Mean sound pressure level measured according to ISO 2151, with an uncertainty of 3 dB(A). Weights of the pack & floor-ounted units are shown in the chart.

| TYPE | Max. working | pressure | Capacity FAD* | Installed motor power | Noise level** |

Wei g ht | ||||

| bar(e) | psig | l/s | m3/min | cfm | kW | hp | dB(A) | kg | lbs | |

| SF 8+-22+ (50/60 Hz) | ||||||||||

| SF 8* | 8 | 116 | 13.4 | 0.80 | 28.4 | 8 | 10 | 63 | 372 | 820 |

| 10 | 145 | 11.4 | 0.68 | 24.2 | 8 | 10 | 63 | 372 | 820 | |

| SF 11+ | 8 | 116 | 20.3 | 1.22 | 43.0 | 11 | 15 | 63 | 418 | 921 |

| 10 | 145 | 15.0 | 0.90 | 31.8 | 11 | 15 | 63 | 418 | 921 | |

| SF 15* | 8 | 116 | 27.1 | 1.63 | 574 | 15 | 20 | 63 | 580 | 1278 |

| 10 | 145 | 23.0 | 1.38 | 48.7 | 15 | 20 | 63 | 580 | 1278 | |

| SF 17* | 8 | 116 | 31.1 | 1.87 | 65.9 | 17 | 22 | 64 | 573 | 1263 |

| 10 | 145 | 23.7 | 1.42 | 50.2 | 17 | 22 | 64 | 573 | 1263 | |

| SF 22+ | 8 | 116 | 40.8 | 2.45 | 86.5 | 22 | 30 | 65 | 687 | 1514 |

| 10 | 145 | 30.0 | 1.80 | 63.6 | 22 | 30 | 65 | 687 | 1514 | |

| SFD 11+-22+(50/60 Hz) | ||||||||||

| SFD 11+ | 8 | 116 | 9.8 | 0.59 | 20.8 | 11 | 15 | 63 | 450 | 992 |

| 10 | 145 | 76 | 0.46 | 16.1 | 11 | 15 | 63 | 450 | 992 | |

| SFD 15+ | 8 | 116 | 13.4 | 0.80 | 28.4 | 15 | 20 | 64 | 625 | 1378 |

| 10 | 145 | 11.4 | 0.68 | 24.2 | 15 | 20 | 64 | 625 | 1378 | |

| SFD 22+ | 8 | 116 | 20.3 | 1.22 | 43.0 | 22 | 30 | 65 | 725 | 1598 |

| 10 | 145 | 15.0 | 0.90 | 31.8 | 22 | 30 | 65 | 725 | 1598 | |

Dimensions

| LxWxH | ||

| mm | inch | |

| SF 1-6/2+-6+ | ||

| Pack & floor-mounted | 760 x 690 x 840 | 29.9×27.2×33.1 |

| Full Feature & floor-mounted | 1025x 690x 840 | 40.4x 27.2x 33.1 |

| Pack & 270l receiver | 1275 x 690x 1450 | 50.2×27.2×57.1 |

| Full Feature & 270l receiver | 1275 x 690x 1450 | 50.2×27.2×57.1 |

| Pack & 500l receiver | 2055x 690 x 1450 | 80.9 x27.2x 57.1 |

| Full Feature & 500l receiver | 2055x 690 x1450 | 80.9 x27.2x 57.1 |

| SF 8+-22+ | ||

| SF 8+-11+ | 1670 x 750x 1230 | 65.7×29.5×48.4 |

| SF 15+-22+ | 1628x 750x 1844 | 64.1 x 29.5x 48.4 |

| SFD 11+-22+ | ||

| SFD 11+-22+ | 1628x750x1844 | 64.1x 29.5x 48.4 |

| SF 1-4 Skid / SF 6-8 Twin | ||

| SF 1-4 Skid FM | 800x600x540 | 31.5×23.6×21.3 |

| SF 1-4 Skid TM | 1267x 600x 1154 | 49.9×23.6×45.4 |

| SF 6-8 Twin | 2043 x600x1154 | 80.4 x 23.6x 45.4 |

Options

| SF 8+-11+ | SF 15+-22+ | SF 17+-22+ | |

| Integrated Refrigerant Dryer | • | • | • |

| EWD for compressor (Pack units only) | • | • | • |

| Extra module upgrade SF 8+ to 15+ | • | – | – |

| Extra module upgrade SF 11+ to 17+ & 22+ | • | – | – |

| Extra module upgrade SF 17+ to 22+ | – | – | • |

| Main switch | • | • | • |

| Audible alarm | • | • | • |

| ES4i & ES6i | • | • | • |

| Wooden package | • | • | • |

| Test certificate | • | • | • |

– : Not available • : Optional

Does your business demand absolutely pure compressed air? Do you have strict requirements for noise levels? Are you looking to significantly reduce operating costs while ensuring seamless production?

Introducing the Atlas Copco SF+ Series 100% Oil-Free Scroll Air Compressors (SF8+, SF11+, SF15+, SF17+, SF22+)!

Designed specifically for your sensitive applications, the SF+ series utilizes unique scroll technology to eliminate oil contamination at the source, providing you with 100% pure, oil-free compressed air. This ensures your products and processes remain completely free from harm.

More than just pure:

- Extremely Silent: Operating noise levels are incredibly low, creating a more comfortable and peaceful working environment. This allows you to place the compressor closer to the point of use, potentially eliminating the need for a dedicated compressor room.

- Exceptional Energy Efficiency: Thanks to intelligent start/stop control, combined with high-efficiency motors and advanced scroll technology, the system precisely matches your air demand. In doing so, it eliminates unloaded power consumption and significantly reduces energy costs. Moreover, the SF+’s unique modular design — with 2 to 4 integrated modules — further enhances system performance by offering unmatched flexibility and reliability.

- Reliable and Durable: Featuring a simple design with fewer moving parts, the SF+ boasts a low failure rate and long service intervals, saving you valuable maintenance time and costs.

- Proven Peace of Mind: As a leader in oil-free air technology, Atlas Copco’s 60+ years of experience and rigorous quality control testing offer you a guarantee of trusted quality.

Don’t let oil contamination, noise, and high energy consumption hinder your production any longer!

Upgrade to an Atlas Copco SF+ 100% Oil-Free Air Compressor today and experience the exceptional value that purity, efficiency, and reliability bring.

Contact us now to get more information and tailored solutions for the SF8+, SF11+, SF15+, SF17+, SF22+ series, and take the first step towards improving the efficiency and quality of your production process!

Anonymous –

I'm thoroughly impressed!

After running our Atlas Copco SF15+ for 6 months in our auto repair shop, I’m thoroughly impressed! The energy savings are noticeable on our power bills – it’s 30% more efficient than our old compressor. Starts up smoothly even in winter, and the 58dB noise level lets us talk normally while it runs. Our productivity has definitely improved!

Seadweer –

We are glad that our products can help you save energy and increase efficiency. Thank you for your feedback.