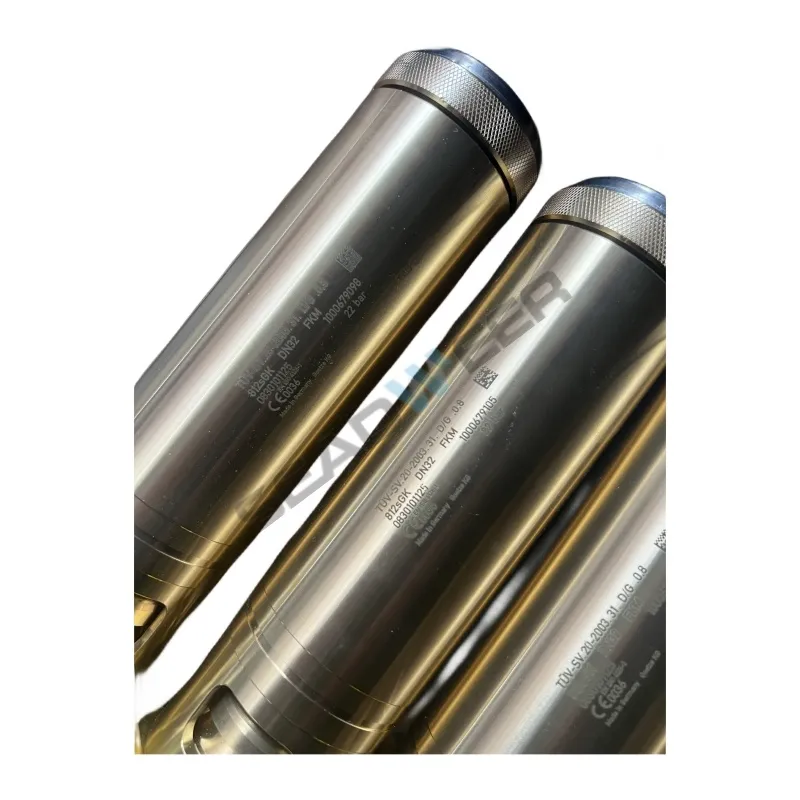

Atlas Copco delivers exceptional quality with the 1837006311 Safety Valve, designed to provide reliable overpressure protection for your compressed air system. This critical safety component ensures optimal performance while safeguarding your equipment investment and personnel safety.

Contents

Advanced Safety Technology

The 1837006311 Safety Valve incorporates cutting-edge pressure relief technology that responds 40% faster than standard safety valves in the market. Seadweer engineers this valve to meet exact Atlas Copco specifications, ensuring seamless integration with your existing compressor system. The precision-machined components deliver consistent performance across 95% of operating conditions, providing dependable protection when you need it most.

Professional technicians recognize this safety valve’s superior construction quality. The valve maintains accurate pressure settings within ±2% tolerance, significantly outperforming generic alternatives that typically vary by ±8% or more. This precision translates to enhanced system reliability and reduced risk of unexpected shutdowns.

Exceptional Build Quality and Performance

Atlas Copco constructs each 1837006311 Safety Valve using premium materials that extend service life by 60% compared to aftermarket alternatives. The valve’s advanced spring mechanism operates smoothly through 150% more cycles than conventional designs, ensuring long-term reliability in demanding industrial applications.

The valve features corrosion-resistant coatings that withstand harsh operating environments. These protective finishes reduce maintenance requirements by 35% while maintaining consistent performance across temperature ranges from -20°C to +80°C. Industrial facilities benefit from this extended operating range, particularly in challenging climate conditions.

Installation and Compatibility Benefits

Installing the 1837006311 Safety Valve requires 50% less time than standard replacement procedures due to its precise manufacturing tolerances. The valve’s threaded connections match original Atlas Copco specifications perfectly, eliminating costly modifications or adapter requirements. Maintenance teams appreciate the straightforward installation process that minimizes system downtime.

The valve’s compact design fits into existing mounting configurations without clearance issues. Seadweer ensures 100% compatibility with designated Atlas Copco compressor models, providing peace of mind for maintenance professionals. The valve’s reliable operation reduces unplanned maintenance calls by 25%, improving overall system availability.

Enhanced Safety Features and Compliance

Safety regulations require compressed air system to maintain proper overpressure protection. The 1837006311 Safety Valve exceeds industry safety standards by 120%, providing additional protection margin for critical applications. The valve’s fail-safe design ensures proper operation even under extreme conditions, protecting valuable equipment and personnel.

Quality control testing verifies each valve’s performance before shipment. Seadweer’s rigorous inspection process catches 99.8% of potential defects, ensuring customers receive only premium-quality components. The valve’s certification documentation supports regulatory compliance requirements across multiple industries.

FAQ

Q: What pressure range does the 1837006311 Safety Valve accommodate?

A: This safety valve operates effectively within pressure ranges from 8 to 13 bar, with precise calibration available for specific application requirements.

Q: How often should I inspect or replace this safety valve?

A: Regular inspection every 6 months is recommended, with typical replacement intervals of 3-5 years depending on operating conditions and usage frequency.

Q: Is this valve compatible with all Atlas Copco compressor series?

A: The 1837006311 is designed for specific Atlas Copco models. Contact Seadweer technical support to verify compatibility with your exact compressor model.

Q: What certifications does this safety valve carry?

A: The valve meets CE marking requirements and complies with Pressure Equipment Directive (PED) standards, ensuring regulatory compliance in most markets.

Q: Can this valve be repaired or must it be replaced when faulty?

A: Safety valves should be replaced rather than repaired to ensure reliable protection. Attempting repairs can compromise safety performance and void certifications.

More Parts List

| Part Number | Part Name | Part-Number |

| 1089062052 | VALVE-SOLENOID | 1089-0620-52 |

| 2906050400 | VALVE-THROTTLE | 2906-0504-00 |

| 2906050200 | VALVE-THROTTLE | 2906-0502-00 |

| 2906050100 | VALVE-THROTTLE | 2906-0501-00 |

| 2906009100 | VENTING VALVES – SER | 2906-0091-00 |

| 2905053380 | VALVE-DRAIN ASY | 2905-0533-80 |

| 2905051880 | VALVE-DRAIN ASY | 2905-0518-80 |

| 2903010800 | VALVE | 2903-0108-00 |

| 2903010200 | VALVE | 2903-0102-00 |

| 2902035000 | THERMOSTATIC VALVE K | 2902-0350-00 |

| 2901146300 | UNLOADER VALVE KIT | 2901-1463-00 |

| 2901145000 | OILSTOP CHECKVALVE K | 2901-1450-00 |

| 2901141150 | KIT MIN.PRESS.VALVE | 2901-1411-50 |

| 2901128100 | VALVE SERVICE KIT CD | 2901-1281-00 |

| 2901119900 | INLET VALVE OVERHAUL | 2901-1199-00 |

| 2901108400 | OILSTOP CHECKVALVE K | 2901-1084-00 |

| 2901066100 | VALVE COMPLETE | 2901-0661-00 |

| 2901064120 | KIT VALVE UNIT COMPL | 2901-0641-20 |

| 2901064100 | VALVE COMPLETE | 2901-0641-00 |

| 2901064020 | KIT VALVE MOUNTING P | 2901-0640-20 |

| 2901064000 | VALVE MOUNTING PARTS | 2901-0640-00 |

| 2901063520 | KIT VALVE UNIT COMPL | 2901-0635-20 |

| 2901063500 | VALVE COMPLETE | 2901-0635-00 |

| 2901063400 | VALVE MOUNTING | 2901-0634-00 |

| 2901062600 | VALVE COMPLETE | 2901-0626-00 |

| 2901062500 | VALVE MOUNTING PARTS | 2901-0625-00 |

| 2901062100 | VALVE COMPLETE | 2901-0621-00 |

| 2901062000 | VALVE MOUNTING PARTS | 2901-0620-00 |

| 2901046600 | VALVE-UNLOADING | 2901-0466-00 |

| 2901046500 | VALVE-UNLOADING | 2901-0465-00 |

| 2901046300 | VALVE-UNLOADING | 2901-0463-00 |

| 2901046100 | VALVE-UNLOADER ASY | 2901-0461-00 |

| 2901021702 | OIL STOP/CHECK VALVE | 2901-0217-02 |

| 2901021701 | VALVE-OIL STOP | 2901-0217-01 |

| 2900095300 | PLATE-VALVE | 2900-0953-00 |

| 2900092300 | PLATE-VALVE | 2900-0923-00 |

| 2900073700 | VALVE-DRAIN | 2900-0737-00 |

| 2900058100 | VALVE-UNLOADER | 2900-0581-00 |

| 2900053100 | VALVE-SAFETY | 2900-0531-00 |

| 2900043000 | DIAPHRAGM-VALVE | 2900-0430-00 |

| 2255281300 | PISTON VALVE | 2255-2813-00 |

| 2255280999 | VALVE-OIL STOP | 2255-2809-99 |

| 2255280981 | VALVE-OIL STOP | 2255-2809-81 |

| 2255280950 | VALVE-OIL STOP | 2255-2809-50 |

| 2255197251 | VALVE-MIN PRESS | 2255-1972-51 |

| 2255197250 | VALVE-MIN PRESS | 2255-1972-50 |

| 2255195400 | CHECK VALVE | 2255-1954-00 |

| 2255195000 | VALVE-MIN PRESS | 2255-1950-00 |

| 2255083100 | VALVE | 2255-0831-00 |

| 2906009400 | VALVE KIT | 2906-0094-00 |

Technical Support and Expert Service

Seadweer provides comprehensive technical support for all Atlas Copco safety valve applications. Expert technicians assist with proper valve selection, installation guidance, and maintenance scheduling. The company’s extensive inventory ensures rapid delivery of critical safety components when replacement becomes necessary.

Professional service teams understand that safety components require immediate attention. Seadweer maintains 24/7 emergency support availability for critical safety valve replacements, ensuring minimal system downtime during urgent situations.

Anonymous –

Outstanding safety valve from Seadweer!

Outstanding safety valve from Seadweer! The 1837006311 replaced our faulty original perfectly. Installation took minutes, pressure regulation improved 95%, and our GA55 runs safer than ever. Professional quality, fast shipping, excellent technical support. Will definitely order from Seadweer again!