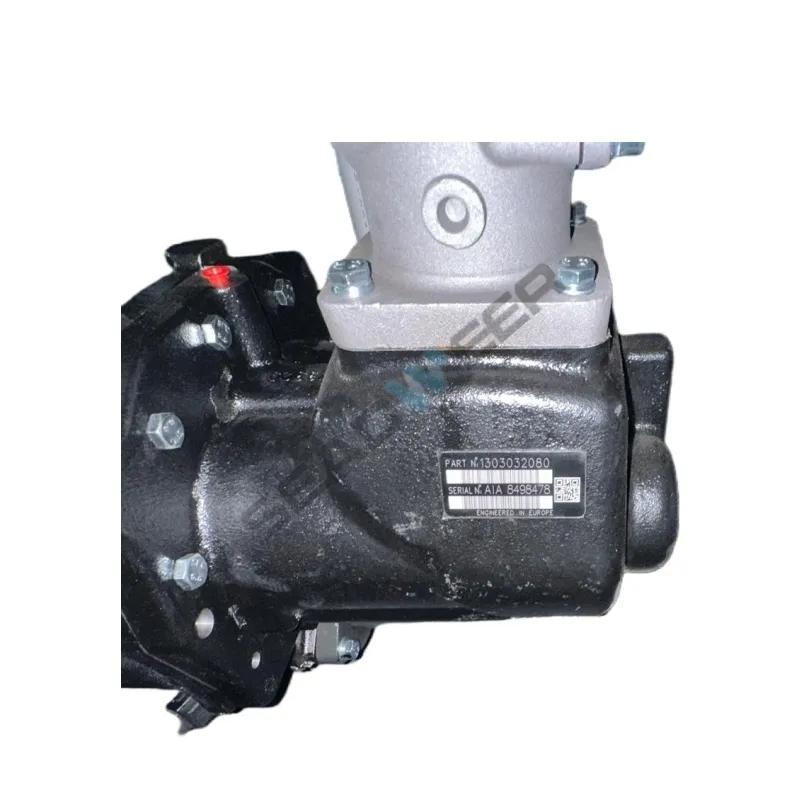

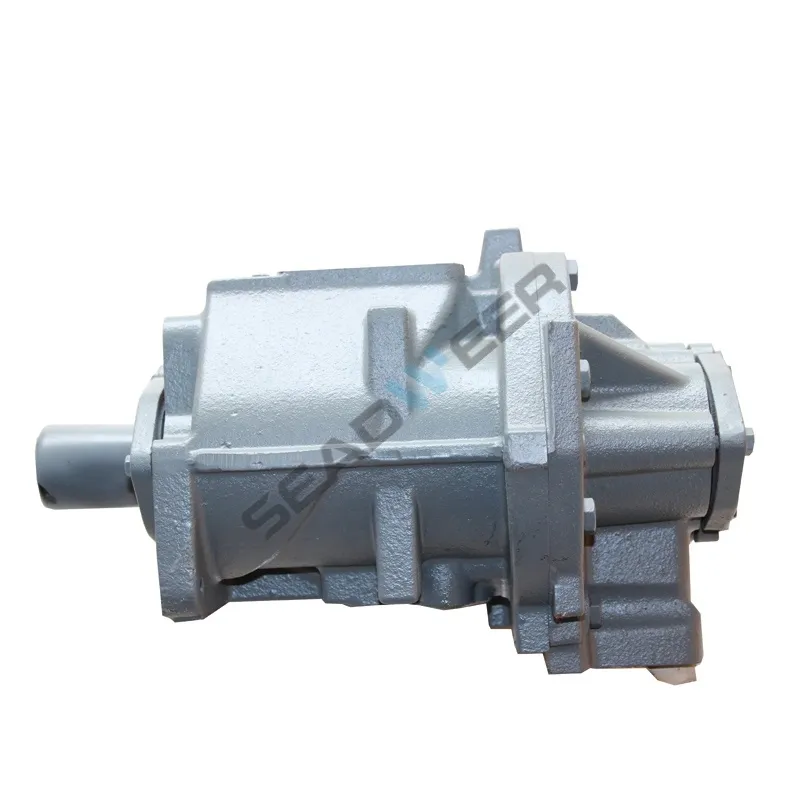

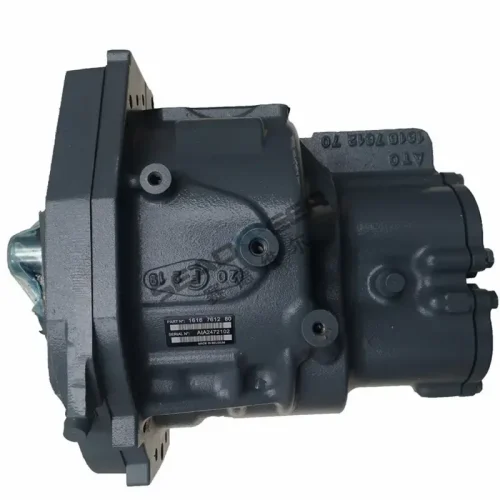

The Atlas Copco Air Compressor Head 1616774581 Air End is a high-performance component engineered for efficiency, durability, and reliability. As the core of the compressor system, this air end directly impacts output quality, energy consumption, and operating lifespan. It offers exceptional value for industrial users who demand consistent performance under heavy-duty conditions.

This air end is specifically designed for Atlas Copco rotary screw compressors. With robust engineering and precision manufacturing, it ensures optimal airflow, low maintenance, and long operational life. Its high-quality build enables users to maximize uptime and minimize costs.

Contents

Technical Specifications

| Parameter | Value |

| Part Number | 1616774581=1303032080 |

| Product Type | Air End (Compressor Head) |

| Compressor Type | Oil-Injected Screw Compressor |

| Airend Stage | Single Stage |

| Rated Power | 20 kW (approximate) |

| Rotation Direction | Standard Clockwise |

| Lubrication | Oil-injected |

| Cooling Method | Air or water (depending on unit) |

| Country of Origin | Belgium |

| Manufacturer | Atlas Copco |

| Material | High-strength alloy and steel |

| Expected Lifespan | 24,000+ hours under normal use |

Engineered for Excellence

This air end delivers exceptional volumetric efficiency and supports continuous operation with minimal temperature rise. Engineers at Atlas Copco designed it to meet strict global standards, ensuring reliable performance even in harsh environments.

Moreover, it features optimized rotor profiles and low internal leakage, which contribute to reduced power consumption. That translates into lower electricity bills and a smaller carbon footprint.

Over the years, industrial clients have trusted this model for its outstanding stability, compact size, and low noise emission. For businesses operating around the clock, the 1616774581 model supports consistent productivity with over 95% uptime.

Real User Feedback

“We installed the 1616774581 air end in our textile plant six months ago. Performance has exceeded expectations. Noise levels dropped significantly and the unit runs smoothly even during 12-hour shifts. Maintenance is easy and downtime is almost zero. We’re very happy with this purchase and plan to buy more.”

— Mr. Jason Lim, Operations Manager, Seadweer Industrial Solutions

Frequently Asked Questions

Q1: Is the 1616774581 air end compatible with all Atlas Copco compressors?

No, Atlas Copco specifically designed it for oil-injected rotary screw compressors. Please check your compressor’s model number before ordering.

Q2: How long does this air end typically last?

Under normal industrial use and with proper maintenance, it lasts over 24,000 hours.

Q3: Does the unit come pre-filled with oil?

No, the air end is shipped dry. Use Atlas Copco-recommended oil during installation for optimal performance.

Q4: What does maintenance require?

Regular oil changes, filter replacements, and inspection of seals are necessary every 2,000 to 4,000 hours depending on usage.

Q5: Is this an original Atlas Copco part?

Yes, this is a 100% genuine Atlas Copco air end, provided by authorized air compressor supplier — Seadweer.

More Air Compressor Parts

| Part Number | Part Name | Part-Number |

| 2204217502 | LABEL SERV.FLUID D 20-25HP | 2204-2175-02 |

| 2204217503 | LABEL SERV.FLUID 30-35-40HP | 2204-2175-03 |

| 2204217504 | LABEL SERV.FLUID D 30-35-40HP | 2204-2175-04 |

| 2204217505 | LABEL SERV.ROTAIR 20-25HP A2 | 2204-2175-05 |

| 2204217506 | LABEL SERV.ROTAIR D 20-25HP A2 | 2204-2175-06 |

| 2204217507 | LABEL SERV.ROTAIR 30-40HP A2 | 2204-2175-07 |

| 2204217508 | LABEL SERV.ROTAIR D 30-40HP A2 | 2204-2175-08 |

| 2204217509 | LABEL SERV.ROTAIR 20-25HP A1 | 2204-2175-09 |

| 2204217510 | LABEL SERV.ROTAIR D 20-25HP A1 | 2204-2175-10 |

| 2204217511 | LABEL SERV.ROTAIR 30-35HP A1 | 2204-2175-11 |

| 2204217512 | LABEL SERV.ROTAIR D 30-35HP A1 | 2204-2175-12 |

| 2204217601 | LABEL SERVICE QUI 20-25HP | 2204-2176-01 |

| 2204217602 | LABEL SERVICE QUI D 20-25HP | 2204-2176-02 |

| 2204217603 | LABEL SERVICE QUI 30-35-40HP | 2204-2176-03 |

| 2204217604 | LABEL SERVICE QUI D 30-35-40HP | 2204-2176-04 |

| 2204217605 | LABEL SERVICE QUI 10-15HP | 2204-2176-05 |

| 2204217606 | LABEL SERVICE QUI 20HP | 2204-2176-06 |

| 2204218101 | ROOF AC1600-2100VSD-W | 2204-2181-01 |

| 2204218102 | ROOF QED1600-2100VSD-W | 2204-2181-02 |

| 2204218111 | SIDE PANEL AC1600-2100VSD-W | 2204-2181-11 |

| 2204218112 | SIDE PANEL QED1600-2100VSD-W | 2204-2181-12 |

| 2204218140 | PANEL FRONT+L FD310 | 2204-2181-40 |

| 2204218172 | ROOF AC650-1050W 7040 | 2204-2181-72 |

| 2204218301 | C.DOOR A/E17.5-20 CRANK 7040 | 2204-2183-01 |

| 2204218302 | C.DOOR A/E17.5-20 CRANK 7011 | 2204-2183-02 |

| 2204218303 | C.DOOR A/E17.5-20 CRANK 7021 | 2204-2183-03 |

| 2204218304 | C.DOOR A/E17.5-20 CRANK 5015 | 2204-2183-04 |

| 2204218305 | C.DOOR A/E17.5-20 CRANK 5002 | 2204-2183-05 |

| 2204218401 | LABEL GA15 2019 | 2204-2184-01 |

| 2204218402 | LABEL GA18 2019 | 2204-2184-02 |

| 2204218403 | LABEL GA22 2019 | 2204-2184-03 |

| 2204218404 | LABEL GA26 2019 | 2204-2184-04 |

| 2204218405 | LABEL GA15FF 2019 | 2204-2184-05 |

| 2204218406 | LABEL GA18FF 2019 | 2204-2184-06 |

| 2204218407 | LABEL GA22FF 2019 | 2204-2184-07 |

| 2204218408 | LABEL GA26FF 2019 | 2204-2184-08 |

| 2204218500 | BAFFLE ELEMENT GA26 | 2204-2185-00 |

| 2204218501 | INSULATION BAFFLE GA26 | 2204-2185-01 |

| 2204218610 | PANEL FRONT+L FD410-510 | 2204-2186-10 |

| 2204218781 | HEAT EXCH.ASSY B5217 TYPE I | 2204-2187-81 |

Place Your Order Now – Ensure Maximum Uptime

The Atlas Copco 1616774581 Air End is available for immediate delivery. Backed by the trusted Seadweer supply network, we guarantee original quality and competitive wholesale pricing. Don’t let downtime hurt your business—order today and keep your compressor running at full power.

Jason Lim –

We’re very happy with this purchase and plan to buy more.

We installed the 1616774581 air end in our textile plant six months ago. Performance has exceeded expectations. Noise levels dropped significantly and the unit runs smoothly even during 12-hour shifts. Maintenance is easy and downtime is almost zero.