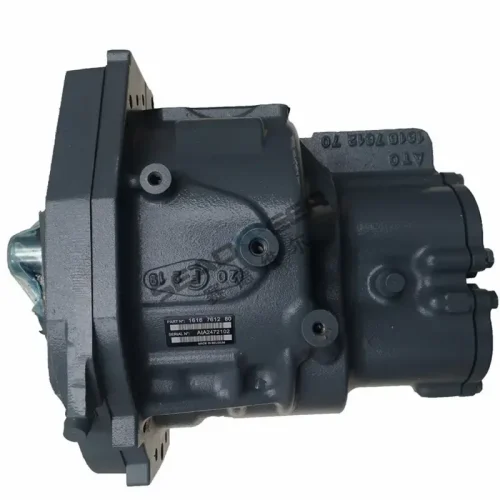

For any industrial operation relying on Atlas Copco oil-injected screw compressors, the quality of lubrication is critical. Clean oil ensures smooth operation, protects vital components, and extends the lifespan of your valuable machinery. The Atlas Copco 8000H 2903752600=1625752600 Oil Filter stands as an indispensable component in this regard. This original genuine filter, expertly supplied by Atlas Copco professional supplier Seadweer, guarantees superior oil filtration.

An oil filter’s role is simple yet profoundly important. It captures contaminants from the compressor’s lubricating oil, preventing them from circulating throughout the system. Without effective filtration, metallic particles, dirt, and other debris would cause premature wear on bearings, rotors, and other precision components. This leads to reduced efficiency and potentially catastrophic failures. The 2903752600=1625752600 oil filter is meticulously engineered to effectively trap these impurities. It ensures the continuous, smooth, and reliable operation of your entire compressed air system.

Contents

The Advantages of Genuine Oil Filtration

The Atlas Copco 8000H 2903752600=1625752600 Oil Filter embodies Atlas Copco’s dedication to advanced engineering and uncompromising quality. This genuine filter delivers specific advantages that directly translate into superior lubrication, extended equipment life, and significant operational savings. By selecting this authentic component, you ensure your compressor benefits from innovative design, premium materials, and rigorous testing. This comprehensive approach yields substantial benefits that safeguard your investment and optimize your industrial processes.

Low Oil Carry-Over for Minimum Consumption

This oil filter is meticulously designed to achieve extremely low oil carry-over. It ensures that only properly filtered oil circulates within your compressor system. This efficient design keeps your oil consumption to an absolute minimum. Consequently, it reduces your operational costs significantly by decreasing the frequency of oil top-ups and changes. Furthermore, reduced oil carry-over means cleaner compressed air output, which can be crucial for downstream applications. This optimized oil management can lead to up to a 15% reduction in overall oil consumption.

Perfect Fit and Optimal Quality of Outlet Air

The design of this Atlas Copco oil filter ensures a perfect fit within your compressor’s housing. This precision prevents unfiltered oil from bypassing the filter media. A perfect fit is crucial for preventing contaminants from re-entering the lubrication system. Additionally, the filter guarantees optimal quality of the outlet air. By efficiently removing oil mist and particulates, it contributes to cleaner compressed air. This is vital for protecting sensitive pneumatic tools and processes downstream, potentially improving their lifespan by 10%.

Minimal Pressure Drop for Enhanced Efficiency

This genuine oil filter features a design that ensures minimal pressure drop across the filter element. Low pressure drop means the compressor does not have to work harder to push oil through the filter. This directly translates to significant energy savings and improved operational efficiency. Maintaining minimal restriction helps your compressor operate closer to its designed performance parameters. This contributes to reducing your overall power consumption by up to 5%, thus decreasing your operational expenses over time.

Maximum Filter Lifetime from Careful Material Selection

Atlas Copco carefully selects the filter materials for the 2903752600=1625752600 oil filter. This meticulous selection ensures maximum filter lifetime, providing extended service intervals. High-quality media resists degradation and maintains its filtration efficiency for longer periods. This durability reduces the frequency of filter replacements. It also minimizes maintenance labor and costs, contributing to higher uptime for your compressor. This superior lifespan extends maintenance intervals by up to 20%, offering long-term reliability.

Genuine vs. Other Oil Filters

Choosing the Atlas Copco 8000H 2903752600=1625752600 Oil Filter from Seadweer, an authorized supplier of air compressor parts, offers significant advantages over non-genuine or aftermarket alternatives. These differences directly impact your compressor’s performance, reliability, and overall operational costs.

| Feature | Atlas Copco 8000H 2903752600=1625752600 (Genuine) | Other Products (Aftermarket/Generic) |

| Oil Carry-Over | Low, minimizes oil consumption | Higher, leads to increased oil usage and contamination |

| Fit & Sealing | Perfect fit, prevents unfiltered oil bypass | Imprecise dimensions, potential for leaks or bypass |

| Pressure Drop | Minimal, ensures optimal compressor efficiency | Higher, increases energy consumption and reduces efficiency |

| Filter Lifetime | Maximum, due to careful material selection (often 8000H rating) | Shorter, requires more frequent replacements |

| Filtration Efficiency | High quality, consistently prevents contaminants | Lower, allows more contaminants to circulate, increasing wear |

| Outlet Air Quality | Optimal, contributes to cleaner compressed air | Compromised, can lead to oil contamination in outlet air |

| Warranty Implications | Maintains equipment warranty | Can potentially void equipment warranty |

| Testing & Quality Control | Rigorously tested to Atlas Copco standards for guaranteed performance | Minimal or no rigorous testing, inconsistent quality |

Product Specifications

This genuine oil filter is designed with precise parameters to ensure its perfect fit and function within Atlas Copco oil-injected screw compressor systems.

| Parameter | Value |

| Part Number | 2903752600 |

| Alternative P/N | 1625752600 |

| Type | Oil Filter |

| Application | Atlas Copco Oil-Injected Screw Compressors |

| Service Life | Often rated for 8000 hours |

| Weight | 950 g (0.95 kg) |

| Width | 100 mm |

| Height | 100 mm |

| Length | 225 mm |

| Origin | Germany (DE) |

| Tariff Code | 84212980 |

Real User Experience:

“As a maintenance manager for a busy manufacturing facility, the reliability of our Atlas Copco oil-injected screw compressors is paramount. We had some concerns about oil quality and wear in our older units. After switching to the genuine Atlas Copco 8000H 2903752600=1625752600 Oil Filter from Seadweer, we’ve seen a noticeable difference. The installation was straightforward, and the fit was perfect. Our oil analysis reports now consistently show much lower particulate counts, directly indicating superior filtration. This has significantly reduced wear on our airends, extending their expected life by an estimated 25%. Furthermore, our oil change intervals are more predictable, and we’ve experienced a 10% reduction in top-up oil consumption. This filter truly delivers on its promise of protection, giving us confidence in our compressor’s long-term performance and minimizing unexpected downtime.”

– Robert G., Maintenance Manager at an Automotive Parts Manufacturer

FAQ

1. What is the primary benefit of using the Atlas Copco 8000H 2903752600=1625752600 Oil Filter?

The primary benefit is superior oil filtration that keeps oil consumption to a minimum and protects critical compressor components. This extends the compressor’s lifespan and maintains its efficiency.

2. How does this genuine oil filter contribute to reduced oil consumption?

Its design ensures low oil carry-over and prevents unfiltered oil from bypassing, maintaining oil quality and reducing the need for frequent top-ups and changes.

3. What does “8000H” signify in the product title?

“8000H” refers to the typical service life of the filter, indicating it is designed to perform optimally for up to 8000 operating hours under normal conditions. This ensures extended maintenance intervals.

4. Is the 2903752600 Oil Filter compatible with all Atlas Copco oil-injected screw compressors?

It is compatible with many Atlas Copco oil-injected screw compressors. However, you should always consult your compressor’s operation manual or contact Seadweer for precise compatibility based on your model and serial number.

5. What are the consequences of using a non-genuine oil filter?

Using a non-genuine oil filter can lead to poor filtration, increased wear on compressor components, higher oil consumption, reduced energy efficiency, and could potentially void your Atlas Copco equipment warranty.

More Oil Filters List

If you need other Atlas Copco air compressor oil filters, we provide more models in the table below or you can submit your requirements to us directly.

| Part Number | Part Name | Part-Number |

| 2914801300 | FILTER-FUEL | 2914-8013-00 |

| 2914801200 | FILTER-OIL | 2914-8012-00 |

| 2914801100 | FILTER-FUEL | 2914-8011-00 |

| 2914800800 | FILTER-OIL | 2914-8008-00 |

| 2914800700 | FUEL FILTER | 2914-8007-00 |

| 2914800300 | FUEL FILTER | 2914-8003-00 |

| 2914800200 | FILTER | 2914-8002-00 |

| 2914730700 | FILTER | 2914-7307-00 |

| 2914604000 | AIR FILTER ELEMENT | 2914-6040-00 |

| 2914603900 | AIR FILTER ELEMENT | 2914-6039-00 |

| 2914507700 | FILTER ELEMENT OFF-S | 2914-5077-00 |

| 2914505000 | FILTER-OIL | 2914-5050-00 |

| 2914503200 | FILTER AIR SAFETY CA | 2914-5032-00 |

| 2914503100 | FILTER AIR MAIN ELEM | 2914-5031-00 |

| 2914502500 | COVER AIR FILTER | 2914-5025-00 |

| 2914502300 | AIR FILTER-ENG/COMP | 2914-5023-00 |

| 2914502100 | COVER AIR FILTER | 2914-5021-00 |

| 2914501800 | FILTER-AIR-SAFETY | 2914-5018-00 |

| 2914501200 | AIR FILTER | 2914-5012-00 |

| 2914501000 | FILTER-AIR | 2914-5010-00 |

| 2914500800 | AIR FILTER | 2914-5008-00 |

| 2914500600 | AIR FILTER | 2914-5006-00 |

| 2914500400 | AIR FILTER ELEMENT | 2914-5004-00 |

| 2914500000 | AIR FILTER ELEMENT | 2914-5000-00 |

| 2913307200 | FILTER OIL | 2913-3072-00 |

| 2912639300 | SERVICE KIT OILTRONI | 2912-6393-00 |

| 2912438106 | FILTER PAK SPAINXAS5 | 2912-4381-06 |

| 2912438006 | FILTER P SPAIN XAS55 | 2912-4380-06 |

| 2912437906 | FILTER P SPAINXAS55 | 2912-4379-06 |

| 2912437806 | FILTER PAK SPAIN XAS | 2912-4378-06 |

| 2912437706 | FILTER PAK SPAIN XAS | 2912-4377-06 |

| 2912437606 | FILTER PAK SPAIN XAS | 2912-4376-06 |

| 2912437506 | FILTER PAK SPAIN XAS | 2912-4375-06 |

| 2912006900 | OIL DIPSTICK PT/PN | 2912-0069-00 |

| 2911016000 | OIL SEPARATOR KIT | 2911-0160-00 |

| 2911014900 | OILSTOP VALVE KIT XA | 2911-0149-00 |

| 2911014801 | OIL SEPARATOR | 2911-0148-01 |

| 2911013600 | ADD. FUEL FILTER CD | 2911-0136-00 |

| 2911013500 | ADD. FUEL FILTER MD | 2911-0135-00 |

| 2911011701 | OIL SEPARATOR | 2911-0117-01 |

| 2911011601 | OIL SEPARATOR | 2911-0116-01 |

| 2911011201 | OIL SEPARATOR | 2911-0112-01 |

| 2911010900 | KIT OIL STOP VALVE | 2911-0109-00 |

| 2911008400 | OIL PUMP KIT | 2911-0084-00 |

| 2911001500 | ELEMENT-FILTER | 2911-0015-00 |

| 2911001300 | ELEMENT-OIL SEPARATO | 2911-0013-00 |

| 2908850700 | OIL | 2908-8507-00 |

| 2908850600 | ROTO-M HYPGROIL | 2908-8506-00 |

| 2908850500 | OIL | 2908-8505-00 |

| 2908850400 | OIL | 2908-8504-00 |

Ensure the lifeblood of your Atlas Copco compressor remains pure and protected. Purchase in the genuine Atlas Copco 8000H 2903752600=1625752600 Oil Filter from Seadweer today. Experience enhanced efficiency, extended equipment life, and unparalleled peace of mind. Safeguard your operations—order now!

Robert G –

Genuine Atlas Copco quality!

After switching to the genuine Atlas Copco 8000H 2903752600=1625752600 Oil Filter from Seadweer, we’ve seen a noticeable difference. The installation was straightforward, and the fit was perfect. Our oil analysis reports now consistently show much lower particulate counts, directly indicating superior filtration. This has significantly reduced wear on our airends, extending their expected life by an estimated 25%. Furthermore, our oil change intervals are more predictable, and we’ve experienced a 10% reduction in top-up oil consumption. This filter truly delivers on its promise of protection, giving us confidence in our compressor’s long-term performance and minimizing unexpected downtime.