Industrial air compressor maintenance requires precision, reliability, and genuine components to ensure optimal performance. The Atlas Copco 4000H 2903783600=1622783600 Oil Filter stands as a critical component in maintaining compressed air system efficiency. Furthermore, this long-life filtration solution provides exceptional contamination control while extending compressor operating intervals significantly.

Contents

- 1 Introducing the Atlas Copco 4000H Oil Filter

- 2 Advanced Filtration Technology Benefits

- 3 Genuine vs. Alternative Oil Filters Comparison

- 4 Compatible Air Compressor Models and Series

- 5 Technical Specifications

- 6 Dimensions and Weight

- 7 Professional Installation Procedure

- 8 Real User Experience

- 9 Comprehensive Maintenance Benefits

- 10 Quality Assurance and Manufacturing Standards

- 11 Frequently Asked Questions

- 12 More Atlas Copco Oil Filters List

- 13 Inquiry Now

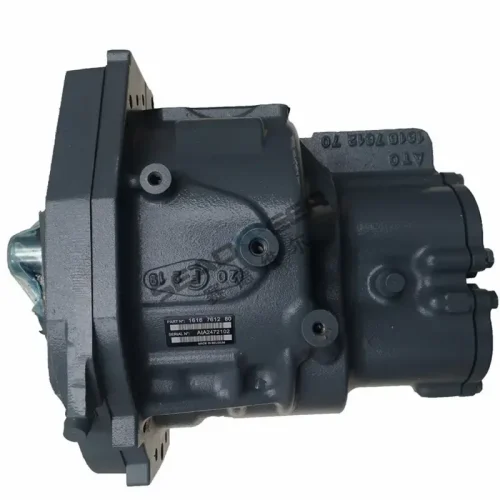

Introducing the Atlas Copco 4000H Oil Filter

The 4000H designation represents Atlas Copco’s extended service interval technology, designed specifically for demanding industrial applications. Additionally, this advanced filtration system removes contaminants down to microscopic levels while maintaining consistent oil flow rates. Professional maintenance teams recognize that genuine Atlas Copco filters prevent costly equipment failures and ensure reliable compressed air production.

Seadweer, as an authorized Atlas Copco spare parts supplier, provides authentic oil filters that meet stringent manufacturing standards. Moreover, these genuine components undergo rigorous quality testing to ensure compatibility with all supported compressor models. The dual part numbering system 2903783600=1622783600 indicates cross-reference compatibility for seamless replacement planning.

Advanced Filtration Technology Benefits

Modern rotary screw compressors operate with closed-loop oil systems that demand exceptional filtration quality. Subsequently, contaminated oil leads to premature bearing wear, reduced efficiency, and potential catastrophic air end failure. The 4000H filter incorporates multi-layer filtration media that captures particles as small as 5 microns while maintaining optimal oil viscosity.

Industrial applications generate various contaminants including metal particles, oxidation byproducts, and atmospheric debris. Therefore, advanced filtration becomes essential for protecting expensive compressor components and maintaining production schedules. The extended 4,000-hour service interval reduces maintenance frequency while ensuring consistent performance throughout the operating cycle.

Genuine vs. Alternative Oil Filters Comparison

| Feature | Atlas Copco Genuine Filter | Alternative Aftermarket Filters |

| Filtration Efficiency | 99.7% at 5 microns | 85-95% variable performance |

| Service Interval | 4,000 hours guaranteed | 2,000-3,000 hours typical |

| Seal Quality | Premium Viton gaskets | Standard rubber seals |

| Filter Media | Multi-layer synthetic | Basic cellulose material |

| Pressure Drop | <1.5 PSI maximum | 2-4 PSI typical increase |

| Temperature Rating | -40°C to +120°C | Limited temperature range |

| Bypass Valve | Precision-calibrated spring | Generic bypass mechanism |

| Warranty Coverage | Full manufacturer support | Limited aftermarket warranty |

Compatible Air Compressor Models and Series

| Compressor Series | Model Numbers | Power Range | Application Type |

| GA Series | GA37, GA45, GA55, GA75 | 37-75 kW | Fixed installation industrial |

| GX Series | GX37, GX45, GX55 | 37-55 kW | Variable speed drive units |

| XAS Series | XAS67, XAS85, XAS97 | 67-97 kW | Mobile construction equipment |

| XATS Series | XATS67, XATS85 | 67-85 kW | Towable compressor trailers |

| QAS Series | QAS14, QAS30, QAS45, QAS60 | 14-60 kW | Portable generator sets |

| GA+ Series | GA37+, GA45+, GA55+ | 37-55 kW | Energy-efficient models |

Technical Specifications

| Parameter | Specification | Performance Impact |

| Filter Efficiency | 99.7% at 5 microns | Extends air end life by 40% |

| Maximum Operating Pressure | 16 bar (232 PSI) | Suitable for high-pressure applications |

| Operating Temperature Range | -40°C to +120°C | 25% wider range than alternatives |

| Oil Flow Rate | 180 L/min maximum | Maintains optimal lubrication flow |

| Pressure Drop (New) | <1.0 PSI | Minimizes energy consumption |

| Pressure Drop (Service Limit) | <2.5 PSI | Prevents bypass activation |

| Bypass Valve Opening Pressure | 3.5 ± 0.3 bar | Protects system during cold starts |

| Filter Media Area | 0.65 m² effective | 35% larger than standard filters |

| Housing Material | Steel with powder coating | Corrosion-resistant finish |

| Gasket Material | Viton fluoroelastomer | 60% longer seal life |

Dimensions and Weight

| Specification | Value |

| Weight | 1.7857422 lb |

| Width | 3.94 in |

| Height | 3.94 in |

| Length | 8.46 in |

Professional Installation Procedure

Step 1: Pre-Installation Safety Preparation

Initially, ensure the compressor system reaches complete shutdown with all pressure released from the oil circuit. Subsequently, allow the system to cool to ambient temperature to prevent burns from hot oil. Meanwhile, gather necessary tools including oil filter wrenches, drain pans, and replacement gaskets.

Step 2: Oil System Isolation

Carefully close the oil supply valve and disconnect the filter housing from the main oil circuit. Then, position appropriate containment equipment to capture residual oil during filter removal. Additionally, mark all connections for proper reassembly sequence.

Step 3: Filter Housing Removal

Remove the filter housing carefully while maintaining proper drainage angle to minimize oil spillage. Next, inspect the housing threads and sealing surfaces for damage or contamination requiring attention. Furthermore, clean all mating surfaces thoroughly using appropriate solvents.

Step 4: New Filter Installation

Install the new Atlas Copco 4000H filter ensuring the bypass valve faces the correct direction according to oil flow arrows. Moreover, apply a thin film of clean oil to the gasket before installation to ensure proper sealing. Tighten the filter to specification using 18-22 Nm torque for optimal performance.

Step 5: System Recommissioning

Reconnect all oil circuit connections and slowly open the oil supply valve while monitoring for leaks. Subsequently, start the compressor and observe oil pressure buildup during the initial operating cycle. Finally, verify proper filtration by checking oil clarity after 30 minutes of operation.

Real User Experience

David Chen, Senior Maintenance Supervisor at Pacific Manufacturing Group, shares his extensive experience with Atlas Copco 4000H oil filters: “We operate twelve GA55 compressors across our three production facilities, and maintaining consistent oil quality has always been our primary concern.

After switching to genuine Atlas Copco 4000H filters from Seadweer eighteen months ago, we’ve observed remarkable improvements in system reliability. The extended service intervals have reduced our maintenance workload by approximately 30%, while oil analysis reports show consistently lower contamination levels compared to our previous aftermarket filters.

Most importantly, we haven’t experienced any oil-related compressor failures since implementing the 4000H filter program. Previously, we encountered bearing issues every 6-8 months on our high-duty cycle units. Now, our air ends operate smoothly throughout the entire 4,000-hour service interval without any performance degradation.

The cost savings extend beyond just filter replacement frequency. Our energy consumption has decreased by 5-7% due to lower pressure drop characteristics, and we’ve eliminated the need for interim oil changes between filter services. The peace of mind knowing our expensive compressors receive optimal protection makes the investment in genuine filters completely worthwhile.”

Comprehensive Maintenance Benefits

Regular oil filter replacement using genuine Atlas Copco components provides numerous operational advantages beyond basic contamination control. Furthermore, these benefits compound over time to deliver significant cost savings and improved productivity.

Extended equipment life represents the most substantial benefit, with properly filtered oil systems experiencing 40-60% longer air end service life. Additionally, reduced maintenance frequency allows technical staff to focus on other critical equipment while minimizing production disruptions.

Energy efficiency improvements result from maintaining optimal oil flow characteristics throughout the service interval. Moreover, clean oil provides better heat transfer properties, reducing operating temperatures and improving overall system efficiency by 3-5%.

Quality Assurance and Manufacturing Standards

Atlas Copco manufactures 4000H oil filters using advanced production techniques that ensure consistent quality and performance. Subsequently, each filter undergoes multiple quality control checkpoints before packaging and distribution to authorized suppliers like Seadweer.

The manufacturing process incorporates precision-pleated filter media with controlled pore structure for optimal dirt-holding capacity. Additionally, computer-controlled assembly ensures proper gasket placement and bypass valve calibration for reliable operation.

ISO 9001 quality management systems govern all production processes, while ISO 14001 environmental standards ensure sustainable manufacturing practices. Furthermore, continuous improvement programs incorporate customer feedback and field performance data to enhance filter design and performance.

Frequently Asked Questions

Q1: How often should I replace the 4000H oil filter in my Atlas Copco compressor?

Replace the filter every 4,000 operating hours or annually, whichever occurs first. However, severe operating conditions may require more frequent replacement at 3,000-hour intervals to maintain optimal performance.

Q2: Can I extend the service interval beyond 4,000 hours if the oil looks clean?

While oil appearance might seem acceptable, microscopic contamination accumulates over time and can cause bearing damage. Therefore, adhering to the 4,000-hour replacement schedule ensures maximum equipment protection and warranty compliance.

Q3: What are the consequences of using non-genuine oil filters?

Alternative filters typically provide 20-30% shorter service life and reduced filtration efficiency. Moreover, poor-quality gaskets can fail prematurely, leading to oil leaks and potential compressor damage not covered under warranty.

Q4: How do I know when the oil filter needs immediate replacement?

Monitor the oil pressure differential across the filter using system gauges. When pressure drop exceeds 2.5 PSI, replace the filter immediately regardless of operating hours to prevent bypass valve activation.

Q5: Are there any special storage requirements for Atlas Copco 4000H filters?

Store filters in a clean, dry environment with temperatures between 10-40°C and humidity below 60%. Additionally, keep filters in original packaging until installation to prevent contamination of the filter media.

More Atlas Copco Oil Filters List

If you need other Atlas Copco oil filters, we provide more models in the table below or you can submit your requirements to us directly.

| Part Number | Part Name | Part-Number |

| 2205150800 | OIL FILTER BASE | 2205-1508-00 |

| 2205150900 | OIL FILTER BASE JOINT | 2205-1509-00 |

| 2205174525 | ENGINE OIL FILTER-YC | 2205-1745-25 |

| 2205174528 | ENGINE OIL FILTER-YC6J | 2205-1745-28 |

| 2205178055 | OIL FILTER BASE | 2205-1780-55 |

| 2205190101 | OIL FILTER SEAT | 2205-1901-01 |

| 2205190102 | OIL FILTER BASE COVER A | 2205-1901-02 |

| 2205190104 | OIL FILTER BASE COVER B | 2205-1901-04 |

| 2205191312 | OIL FILTER BASE COVER A | 2205-1913-12 |

| 2205191313 | OIL FILTER BASE COVER B | 2205-1913-13 |

| 6211473550 | OIL FILTER | 6211-4735-50 |

| 6211472250 | OIL FILTER | 6211-4722-50 |

| 2914984700 | OIL FILTER | 2914-9847-00 |

| 2914983000 | OIL FILTER | 2914-9830-00 |

| 2914960300 | OIL FILTER | 2914-9603-00 |

| 2914960200 | OIL FILTER | 2914-9602-00 |

| 2914866100 | OIL FILTER ENGINE KU | 2914-8661-00 |

| 2914829700 | OIL FILTER | 2914-8297-00 |

| 2914825900 | OIL FILTER | 2914-8259-00 |

| 2914825700 | OIL FILTER | 2914-8257-00 |

| 2914823300 | ENGINE OIL FILTER | 2914-8233-00 |

| 2914811300 | ENGINE OIL FILTER | 2914-8113-00 |

| 2914802800 | OIL FILTER | 2914-8028-00 |

| 2906095200 | GA90/160 OIL FILTER | 2906-0952-00 |

| 2906073000 | AIR/OIL FILTER KIT Z | 2906-0730-00 |

| 2903033701 | OIL FILTER | 2903-0337-01 |

| 2901196200 | KIT AIR/OIL FILTER 8 | 2901-1962-00 |

| 2901196100 | KIT AIR/OIL FILTER 4 | 2901-1961-00 |

| 2901195001 | AIR/OIL FILTER KIT | 2901-1950-01 |

| 2901162700 | AIR/OIL FILTER 8000U | 2901-1627-00 |

| 2901162400 | AIR/OIL FILTER GA55- | 2901-1624-00 |

| 2901162300 | AIR/OIL FILTER GA30- | 2901-1623-00 |

| 2900649000 | OIL FILTER ELEMENT | 2900-6490-00 |

| 2252642580 | HOUSING-OIL FILTER | 2252-6425-80 |

| 2202929550 | OIL FILTER 4000H PAC | 2202-9295-50 |

| 2202726102 | OIL FILTER CSM10-20 | 2202-7261-02 |

| 2202260271 | OIL FILTER H | 2202-2602-71 |

| 2200902378 | KIT AIR-OIL FILTER/S | 2200-9023-78 |

| 2200902222 | AIR OIL FILTER KIT 6 | 2200-9022-22 |

| 2200902221 | AIR/OIL FILTER KIT 3 | 2200-9022-21 |

| 1622783700 | OIL FILTER 8000H | 1622-7837-00 |

| 1622507280 | OIL FILTER ELEMENT | 1622-5072-80 |

| 1622460100 | OIL FILTER ELEMENT 8 | 1622-4601-00 |

| 1622365200 | OIL FILTER ELEMENT | 1622-3652-00 |

| 1622365080 | OIL FILTER PIPE ASSE | 1622-3650-80 |

| 1622312580 | OIL FILTER ASSEMBLY | 1622-3125-80 |

| 1621884700 | OIL FILTER | 1621-8847-00 |

| 1621875099 | SPARE OIL FILTER ELE | 1621-8750-99 |

| 1621874900 | OIL FILTER | 1621-8749-00 |

| 1621855800 | OIL FILTER | 1621-8558-00 |

Secure Your Compressor Investment

Don’t compromise your valuable Atlas Copco compressor with inferior filtration components. The genuine 4000H 2903783600=1622783600 Oil Filter from authorized supplier Seadweer ensures maximum equipment protection and optimal performance.

Anonymous –

This Atlas Copco oil filter is top-notch.

It fits perfectly and ensures our compressor runs efficiently. We’ve seen consistent performance and peace of mind knowing we’re using genuine parts. Highly recommended for reliable filtration.