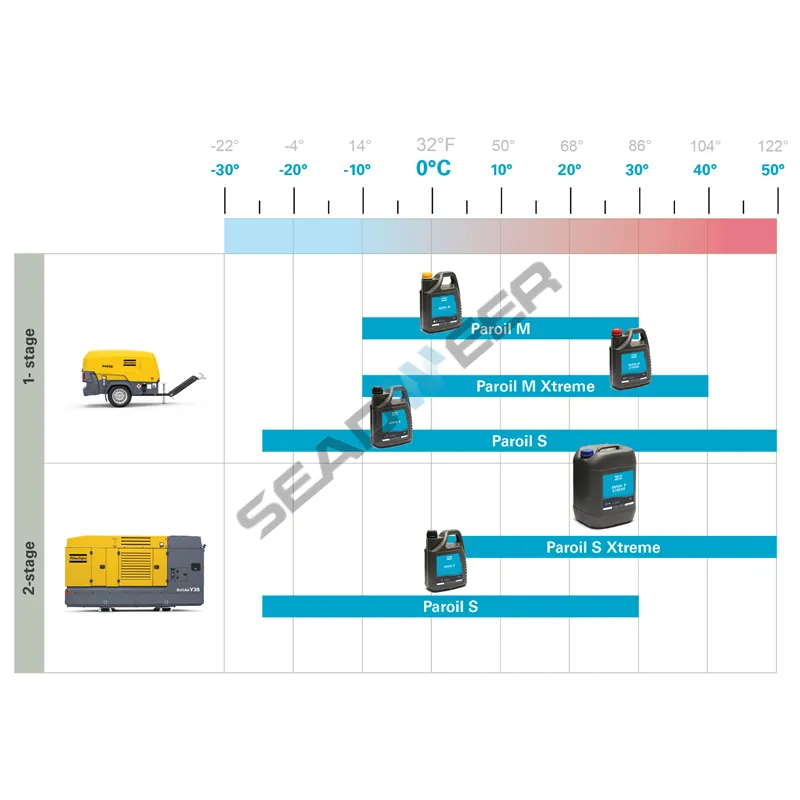

Industrial mobile compressors demand high-quality lubricants to maintain optimal performance across demanding applications. Furthermore, selecting the appropriate compressor oil ensures equipment longevity and operational reliability. Seadweer, a trusted Atlas Copco supplier, provides genuine Atlas Copco 20L PAROIL M lubricant oil 1615594800 that delivers exceptional protection for single-stage mobile compressors.

Contents

- 1 Understanding PAROIL M’s Advanced Formulation

- 2 Genuine vs. Alternative Products Comparison

- 3 Compatible Air Compressor Models

- 4 Technical Specifications and Dimensions

- 5 Installation and Oil Change Procedure

- 6 Experience from Professional Users

- 7 Frequently Asked Questions

- 8 Expert Recommendation and Quality Assurance

- 9 More Lubricants List

- 10 Conclusion

- 11 Inquiry Now

Understanding PAROIL M’s Advanced Formulation

PAROIL M represents a mineral-based, premium-quality air compressor oil with a high viscosity index and specialized additives designed for critical applications. Additionally, this advanced formulation provides superior anti-wear properties and film strength characteristics. The oil maintains consistent performance across various operating conditions while protecting vital internal components.

Moreover, PAROIL M oil is formulated with specialized additives and a high viscosity index, delivering outstanding performance characteristics for demanding applications. This careful engineering ensures optimal lubrication under extreme pressures and temperatures common in mobile compressor operations.

Genuine vs. Alternative Products Comparison

| Feature | Atlas Copco PAROIL M | Alternative Products |

| Viscosity Index | 105-115 | 85-95 |

| Operating Temperature | -25°C to +50°C | -10°C to +40°C |

| Service Life | 2000-2500 hours | 1200-1800 hours |

| Oxidation Resistance | Excellent | Good |

| Carbon Formation Control | 99% effective | 75-85% effective |

| Thermal Stability | Superior | Standard |

| Pour Point | -30°C | -15°C |

| Flash Point | 220°C | 190°C |

| Water Separation | 95% | 70-80% |

Compatible Air Compressor Models

| Series | Models | Application Type |

| XAHS Series | XAHS186, XAHS286, XAHS376 | Single-stage mobile |

| XAMS Series | XAMS850, XAMS1070 | Single-stage mobile |

| XAS Series | XAS67, XAS87, XAS97 | Single-stage portable |

| XAVS Series | XAVS186, XAVS400 | Single-stage towable |

| XA Series | XA47, XA67, XA77 | Single-stage mobile |

| XRXS Series | XRXS366, XRXS566 | Single-stage rental |

Technical Specifications and Dimensions

Technical information

| Parameter | Specification |

| Part Number | 1615594800 |

| Container Size | 20 Liters |

| Oil Type | Mineral-based premium |

| ISO Viscosity Grade | VG 46 |

| Kinematic Viscosity (40°C) | 46 mm²/s |

| Viscosity Index | 105 minimum |

| Pour Point | -30°C maximum |

| Flash Point | 220°C minimum |

| Specific Gravity (15°C) | 0.87 |

| Total Acid Number | 0.5 mg KOH/g maximum |

| Sulfur Content | 0.3% maximum |

Dimensions

| Width | 230 mm |

| Height | 370 mm |

| Length | 290 mm |

| Weight | 18419 gr |

Installation and Oil Change Procedure

Proper oil change procedures ensure maximum lubricant effectiveness and equipment protection. Follow these essential steps:

Step 1: System Preparation

Allow the compressor to cool completely before beginning maintenance procedures. Subsequently, engage all safety lockouts and position the unit on level ground. Then, gather necessary tools including drain pans and appropriate wrenches.

Step 2: Oil Drainage

Remove the drain plug while the oil remains slightly warm for better flow characteristics. Additionally, allow complete drainage for at least 15 minutes to remove contaminated oil. Clean the drain plug and inspect the magnetic tip for metal particles.

Step 3: Filter Replacement

Replace the oil filter during each oil change to maintain filtration effectiveness. Furthermore, apply a thin layer of new oil to the filter gasket before installation. Tighten according to manufacturer specifications without over-torquing.

Step 4: Refill Process

Add PAROIL M through the designated fill port using appropriate funnels to prevent contamination. Moreover, fill gradually while monitoring the dipstick to avoid overfilling. The proper level should reach between minimum and maximum marks.

Step 5: System Check

Run the compressor for several minutes and check for leaks around connections. Additionally, verify oil pressure readings match normal operating parameters. Finally, document the service date and oil quantity for maintenance records.

Experience from Professional Users

Mike Thompson, Equipment Manager at Construction Solutions Inc., shares his comprehensive experience with Atlas Copco PAROIL M:

“Our fleet of 25 Atlas Copco mobile compressors operates in harsh construction environments across the Southwest. Initially, we experimented with alternative lubricants to reduce operating costs. However, increased maintenance issues and premature component wear quickly eliminated any perceived savings.

Since switching to genuine PAROIL M lubricant from Seadweer, our operational efficiency improved dramatically. The oil change intervals extended by 30% while maintaining superior protection levels. Furthermore, our compressor downtime decreased by 18% due to reduced component failures and maintenance requirements.

What impressed us most was the oil’s performance during extreme summer conditions. Even when ambient temperatures exceeded 45°C, PAROIL M maintained consistent viscosity and protection levels. Our technicians noticed significantly cleaner internal components during routine inspections, indicating excellent detergent properties and carbon control.”

Frequently Asked Questions

Q1: How often should I change PAROIL M in my mobile compressor? Change intervals depend on operating conditions, but typically range from 1500-2500 hours. However, severe conditions may require more frequent changes to maintain optimal protection.

Q2: Can PAROIL M mix with other compressor oils? While emergency mixing may be acceptable, avoid regular mixing practices. Furthermore, complete oil changes ensure 100% compatibility and optimal performance characteristics.

Q3: What happens if I use incorrect oil viscosity? Wrong viscosity can reduce lubrication effectiveness by 20-30% and potentially cause component damage. Therefore, always use the specified ISO VG 46 grade for optimal protection.

Q4: How do I identify genuine PAROIL M? Authentic products feature Atlas Copco holographic security labels and precise part number markings. Additionally, authorized suppliers provide certificates of authenticity with each purchase.

Q5: Does PAROIL M work in extreme temperature conditions? Yes, PAROIL M maintains 95% of its protective properties across the -25°C to +50°C temperature range, making it suitable for diverse climate conditions.

Expert Recommendation and Quality Assurance

Professional maintenance experts consistently recommend genuine Atlas Copco PAROIL M for several critical reasons. First, the oil’s advanced additive package provides superior protection against wear and oxidation. Additionally, the high viscosity index ensures consistent performance across temperature variations.

Furthermore, using genuine lubricants maintains warranty coverage and ensures regulatory compliance. The investment in quality lubricants proves cost-effective through extended equipment life and reduced maintenance expenses.

Recommend Read:How to select the right oil for your atlas copco air compressor?

More Lubricants List

If you need other Atlas Copco air compressor lubricants, we provide more models in the table below or you can submit your requirements to us directly.

| 3002606200 | 18L 4K LUBRICANT OIL | 3002-6062-00 |

| 3002606201 | 209L 4K LUBRICANT OIL | 3002-6062-01 |

| 3003100220 | IR LUBRICANT 5 GALLON | 3003-1002-20 |

| 3003102720 | SU 24KT LUBRICANT 5 GALLON | 3003-1027-20 |

| 3003201568 | SYN-COOLANT/6/LUBRICANTS(5GAL) | 3003-2015-68 |

| 6996013040 | LUBRICATOR, 1/4+ | 6996-0130-40 |

| 2914866000 | LUBRICATING OIL FILT | 2914-8660-00 |

| 2908851500 | SILUBRIN S GREASE 1 | 2908-8515-00 |

| 2908007800 | LUBRICANT | 2908-0078-00 |

| 1901025737 | Lubricating nipple | 1901-0257-37 |

| 1901026195 | Lubricating nipple | 1901-0261-95 |

| 1901055459 | Lubricating nipple | 1901-0554-59 |

| 1901603510 | EXTENSION FOR LUBRICATOR | 1901-6035-10 |

| 1901603530 | LUBRICATOR M8X125 DROIT | 1901-6035-30 |

| 1901900256 | LUBRIFICATOR KIT | 1901-9002-56 |

| 1904202504 | Lubricator Outlet Check Valve | 1904-2025-04 |

| 2024601401 | QUIN-CIP LUBRICANT 1QUART GALL | 2024-6014-01 |

| 1630850000 | LUBRICATOR | 1630-8500-00 |

| 1630850001 | LUBRICATOR | 1630-8500-01 |

| 1630850002 | LUBRICATOR | 1630-8500-02 |

| 1630850006 | LUBRICATOR | 1630-8500-06 |

| 1630850007 | LUBRICATOR | 1630-8500-07 |

| 1630850008 | LUBRICATOR | 1630-8500-08 |

| 1630850009 | LUBRICATOR | 1630-8500-09 |

| 1630850010 | LUBRICATOR | 1630-8500-10 |

| 1310034936 | LUBRICATOR | 1310-0349-36 |

| 1306012300 | HOUSING-LUBRICATING | 1306-0123-00 |

| 1091505300 | LUBRICATOR | 1091-5053-00 |

| 1091503700 | LUBRICATOR | 1091-5037-00 |

| 2205421501 | LUBRICATING OIL | 2205-4215-01 |

| 2205421502 | LUBRICATING SYNTHETIC OIL | 2205-4215-02 |

| 2205421504 | LUBRICATING OIL | 2205-4215-04 |

| 2205421511 | LUBRICATING SYNTHETIC OIL | 2205-4215-11 |

| 2235798200 | LUBRICANT GREASE TUBE 5 GRAMS | 2235-7982-00 |

| 1621506392 | LUBRICATING DISK | 1621-5063-92 |

| 1621506394 | LUBRICATING DISK | 1621-5063-94 |

| 1621506414 | LUBRICATING DISK | 1621-5064-14 |

| 1621506416 | LUBRICATING DISK | 1621-5064-16 |

| 1621506421 | LUBRICATING DISK | 1621-5064-21 |

| 1621506422 | LUBRICATING DISK | 1621-5064-22 |

| 1621506424 | LUBRICATING DISK | 1621-5064-24 |

| 1621506428 | LUBRICATING DISK | 1621-5064-28 |

| 1621506432 | LUBRICATING DISK | 1621-5064-32 |

| 1621506449 | LUBRICATING DISK | 1621-5064-49 |

| 1621506452 | LUBRICATING DISK | 1621-5064-52 |

| 1621506455 | LUBRICATING DISK | 1621-5064-55 |

| 1621506547 | LUBRICATING DISK | 1621-5065-47 |

| 1621506821 | LUBRICATING DISK | 1621-5068-21 |

| 1091503700 | LUBRICATOR | 1091-5037-00 |

Conclusion

Atlas Copco 20L 1615594800 PAROIL M lubricant oil represents the gold standard for single-stage mobile compressor protection. Moreover, choosing genuine products through professional suppliers like Seadweer ensures optimal performance and reliability.

The superior formulation and proven track record make PAROIL M the preferred choice among industry professionals. Furthermore, the comprehensive protection and extended service intervals provide exceptional value for demanding applications.

References

1.Atlas Copco Official Lubricants Portfolio: https://www.atlascopco.com/en-us/construction-equipment/service/fluids-and-lubricants-portfolio

2.International Organization for Standardization – Lubricant Standards: https://www.iso.org/committee/52404.html

3.Society of Automotive Engineers – Lubricant Classifications: https://www.sae.org/standards/content/j300_202104

Anonymous –

Great quality product and excellent service.

Top-notch PAROIL M oil from Seadweer! Our Atlas Copco compressor loves it – running smoothly and efficiently. Great quality product and excellent service.