As an authorized distributor of Atlas Copco, Seadweer Air Compressor Co., Ltd. is proud to supply the genuine Oil Filter Element (Part Number: 1625840180, equivalent to 1625840080). This premium filter is engineered to deliver exceptional protection and performance for your compressed air systems, ensuring operational reliability and efficiency.

Contents

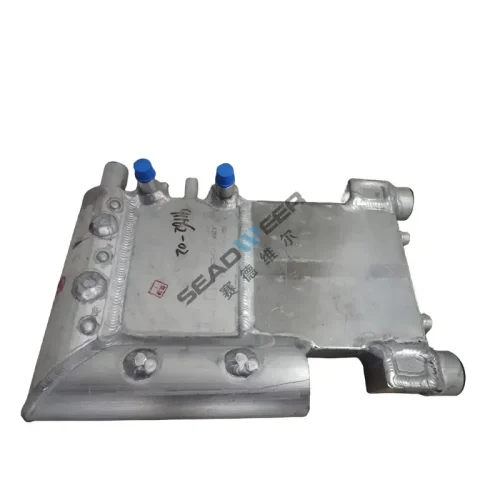

Product Overview

Atlas Copco designed this oil filter element for superior contaminant removal in compressor applications. It features a unique sealing system and specialized filtration media that work in unison to safeguard your compressor elements. The specially designed filtration paper incorporates precise indentations that effectively capture and retain harmful particles while maintaining optimal airflow. This design prevents contaminants from reaching critical components, maximizing your system’s process efficiency and longevity.

Technical Specifications

| Parameter | Specification |

| Part Number | 1625840180 / 1625840080 |

| Manufacturer | Atlas Copco |

| Origin | Germany (DE) |

| Tariff Code | 84219990 |

| Width | 90 mm |

| Height | 90 mm |

| Length | 255 mm |

| Weight | 310 grams |

Product Advantages

- Exceptional Filtration Performance: The element traps microscopic particles down to 3 microns in size, preventing 99.9% of contaminants from entering and damaging the compressor’s core elements.

- Engineered for Efficiency: Developed with a focus on maximum dust holding capacity, high separation efficiency, and minimized flow restriction, ensuring consistent pressure and lower energy consumption.

- Unique Sealing & Media Design: The proprietary seal guarantees leak-free operation, while the indented filtration paper structure ensures high dirt capture without impeding incoming air flow.

- Proven Reliability: As a genuine Atlas Copco part, it guarantees perfect compatibility and performance, protecting your investment and reducing unscheduled downtime.

- Optimized Service Life: The high dust-holding capacity extends service intervals, providing long-lasting protection and reducing total maintenance costs.

FAQ

What is the filtration efficiency of this oil filter element?

This element provides highly efficient filtration, capturing particles down to 3 microns and preventing 99.9% of contaminants from passing through.

Are the two part numbers (1625840180 and 1625840080) identical?

Yes, the part numbers 1625840180 and 1625840080 are equivalents. They refer to the same genuine Atlas Copco Oil Filter Element.

What are the main benefits of the unique filtration paper design?

The specially indented paper maximizes surface area for dust capture, significantly increasing dirt holding capacity while maintaining low air flow resistance for optimal compressor efficiency.

Why is using a genuine Atlas Copco filter important?

Genuine filters are specifically engineered to meet the exact requirements of your Atlas Copco air compressor. They ensure specified performance, protect your warranty, and provide the reliability and service life promised by the original equipment design.

Where is this filter element manufactured?

This genuine Atlas Copco Oil Filter Element manufactured in Germany (DE), adhering to strict global quality standards.

More Filters List

If you need other Atlas Copco air compressor filters, we provide more models in the table below or you can submit your requirements to us directly.

| Part Number | Part Name | Part-Number |

| 2205618817 | AIR FILTER BLT | 2205-6188-17 |

| 2205618818 | AIR FILTER BLT | 2205-6188-18 |

| 2205618886 | AIR FILTER ELEMENT BLT | 2205-6188-86 |

| 2205618894 | AIR FILTER ELEMENT | 2205-6188-94 |

| 2205618996 | AIR FILTER ASSEMBLY | 2205-6189-96 |

| 2205618998 | AIR FILTER ASSEMBLY | 2205-6189-98 |

| 2205619157 | AIR FILTER ASSEMBLY | 2205-6191-57 |

| 2205619329 | 1m3/min AIR FILTER ELEMENT | 2205-6193-29 |

| 2205619376 | AIR FILTER ASSEMBLY | 2205-6193-76 |

| 2205619378 | OIL FILTER W950 (BP LOGO) | 2205-6193-78 |

| 2205677429 | FILTER | 2205-6774-29 |

| 2205685302 | FILTER DRYER DML033S | 2205-6853-02 |

| 2205721521 | AIR FILTER BOX | 2205-7215-21 |

| 2205721534 | PANEL FILTER | 2205-7215-34 |

| 2205721535 | PANEL FILTER, HOLDER | 2205-7215-35 |

| 2205721542 | AIR FILTER | 2205-7215-42 |

| 2205721700 | AIR FILTER BOX | 2205-7217-00 |

| 2205721701 | AIR FILTER. | 2205-7217-01 |

| 2205721714 | PANEL FILTER, 340X270 | 2205-7217-14 |

| 2205721749 | AIR FILTER BOX | 2205-7217-49 |

| 2205721750 | AIR FILTER | 2205-7217-50 |

| 2205721814 | PANEL FILTER, 535X960 | 2205-7218-14 |

| 2205721815 | PANEL FILTER, 515X880 | 2205-7218-15 |

| 2205721816 | PANEL FILTER, 735X1020 | 2205-7218-16 |

| 2205721817 | PANEL FILTER, 400X470 | 2205-7218-17 |

| 2205721818 | PANEL FILTER 365X400 | 2205-7218-18 |

| 2205721837 | PANEL FILTER, 345X195 | 2205-7218-37 |

| 2205721838 | PANEL FILTER, 287X192 | 2205-7218-38 |

| 2205721883 | OIL FILTER SEAT | 2205-7218-83 |

| 2205721962 | OIL FILTER SEAT, MANN | 2205-7219-62 |

| 2205721984 | PANEL FILTER | 2205-7219-84 |

| 2205721991 | AIR FILTER BOX | 2205-7219-91 |

| 2205721992 | AIR FILTER | 2205-7219-92 |

| 2205721993 | ADAPTOR, AIR FILTER BOX | 2205-7219-93 |

| 2205722051 | PREFILTER | 2205-7220-51 |

| 2205722082 | PANEL FILTER, 550X660 | 2205-7220-82 |

| 2205722083 | PANEL, FILTER, 405X1090 | 2205-7220-83 |

| 2205722103 | PREFILTER | 2205-7221-03 |

| 2205722104 | PREFILTER | 2205-7221-04 |

| 2205722105 | PREFILTER | 2205-7221-05 |

| 2205722110 | PANEL, FILTER, 74X103 | 2205-7221-10 |

| 2205722127 | PREFILTER | 2205-7221-27 |

| 2205722128 | PREFILTER | 2205-7221-28 |

| 2205722136 | PREFILTER | 2205-7221-36 |

| 2205722137 | PREFILTER | 2205-7221-37 |

| 2205722151 | HARMONIC FILTER, 28.E4.T60-100 | 2205-7221-51 |

| 2205722229 | OIL FILTER SEAT | 2205-7222-29 |

| 2205722258 | OIL FILTER SEAT, MANN | 2205-7222-58 |

| 2205722277 | CUBICLE DOOR, PANEL FILTER HOU | 2205-7222-77 |

| 2205722280 | PANEL FILTER, 44X66 | 2205-7222-80 |

Anonymous_buyer –

The difference in build quality is noticeable.

Our compressor’s oil pressure was dropping prematurely between changes. Switched to this genuine filter element from Seadweer—now we get consistent pressure for the full 4000-hour service interval. The difference in build quality is noticeable.