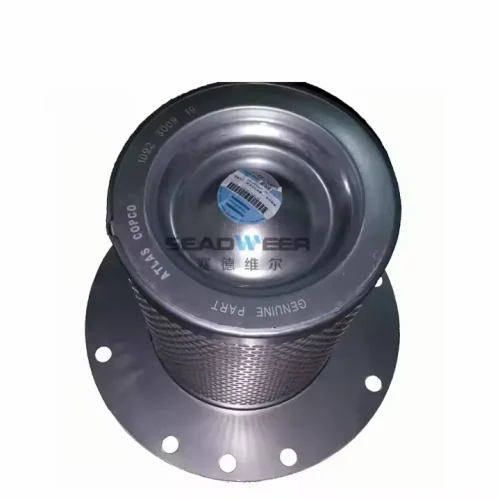

Industrial compressed air systems demand precise oil separation to maintain air quality and protect downstream equipment. The Atlas Copco 1625481151=1625481101 Oil Separator delivers exceptional performance for oil-injected screw compressors. Furthermore, this critical component ensures clean compressed air while preventing costly contamination issues in production environments.

Contents

- 1 Atlas Copco Oil Separation Technology

- 2 Critical Role in Compressed Air Quality

- 3 Genuine vs. Alternative Oil Separators

- 4 Compatible Air Compressor Models and Series

- 5 Technical Specifications

- 6 Dimensions and Weight

- 7 Professional Installation Procedure

- 8 User Feedback

- 9 Frequently Asked Questions

- 10 More Oil separators List

- 11 Inquiry Now

Atlas Copco Oil Separation Technology

Oil separation represents the final stage in compressed air production for rotary screw compressors. Additionally, this process removes oil droplets and vapor from compressed air streams using advanced filtration media. Professional maintenance teams recognize that genuine Atlas Copco oil separators provide superior separation efficiency compared to alternative components.

Seadweer, as an authorized Atlas Copco specialist supplier, provides authentic oil separators that meet stringent manufacturing standards. Moreover, these genuine components undergo rigorous quality testing to ensure optimal performance across all supported compressor models. The dual part numbering system (1625481151=1625481101) indicates cross-reference compatibility for simplified procurement and inventory management.

Critical Role in Compressed Air Quality

Modern manufacturing processes require oil-free compressed air to prevent product contamination and equipment damage. Subsequently, inadequate oil separation leads to downstream corrosion, pneumatic component failure, and product quality issues. The Atlas Copco separator achieves 99.9% oil removal efficiency while maintaining minimal pressure drop characteristics.

Industrial applications including pharmaceutical manufacturing, food processing, and electronics assembly demand extremely clean compressed air. Therefore, high-performance oil separation becomes essential for meeting stringent quality standards and regulatory requirements. The extended service interval of 4,000 hours reduces maintenance frequency while ensuring consistent air quality throughout the operating cycle.

Genuine vs. Alternative Oil Separators

| Feature | Atlas Copco Genuine Separator | Alternative Aftermarket Units |

| Oil Removal Efficiency | 99.9% guaranteed performance | 95-98% variable efficiency |

| Service Interval | 4,000 hours or 2 years | 2,500-3,500 hours typical |

| Pressure Drop (New) | <0.5 PSI maximum | 1-2 PSI higher resistance |

| Filter Media Quality | Borosilicate microfiber | Standard glass fiber material |

| Gasket Material | Viton high-temperature seals | Basic rubber gaskets |

| Collapse Resistance | 15 PSI differential rating | 8-12 PSI maximum rating |

| Temperature Rating | -40°C to +120°C | Limited temperature range |

| Warranty Coverage | Full manufacturer support | Limited aftermarket warranty |

Compatible Air Compressor Models and Series

| Compressor Series | Model Numbers | Power Range | Application Type |

| GA Series | GA18, GA22, GA26, GA30, GA37 | 18-37 kW | Fixed installation industrial |

| GA+ Series | GA18+, GA22+, GA26+, GA30+ | 18-30 kW | Energy-efficient models |

| GA VSD+ Series | GA18 VSD+, GA22 VSD+, GA26 VSD+ | 18-26 kW | Variable speed drive units |

| XATS Series | XATS138, XATS148 | 138-148 kW | Towable construction equipment |

| GX Series | GX18, GX22, GX26 | 18-26 kW | Premium efficiency compressors |

| G Series | G18, G22, G26, G30 | 18-30 kW | Standard industrial models |

Technical Specifications

| Parameter | Specification | Performance Impact |

| Oil Removal Efficiency | 99.9% at operating pressure | Meets ISO 8573-1 Class 1 standards |

| Maximum Operating Pressure | 13 bar (188 PSI) | Suitable for high-pressure systems |

| Operating Temperature Range | -40°C to +120°C | 30% wider range than alternatives |

| Initial Pressure Drop | <0.5 PSI | Minimizes energy consumption |

| Service Limit Pressure Drop | 7-8 PSI maximum | Prevents compressor damage |

| Filter Media Area | 2.1 m虏 effective surface | 45% larger than standard separators |

| Housing Diameter | 165mm external | Compact design for space constraints |

| Overall Height | 420mm including connections | Standard vessel compatibility |

| Gasket Material | Viton fluoroelastomer | 50% longer seal life |

| Collapse Rating | 15 PSI differential | Prevents media failure |

Dimensions and Weight

| Specification | Value |

| Weight | 5.8091737 lb |

| Width | 5.71 in |

| Height | 5.71 in |

| Length | 12.32 in |

Professional Installation Procedure

Step 1: System Preparation and Safety

Initially, ensure the compressor system reaches complete shutdown with all pressure released from the air receiver. Subsequently, isolate electrical power and lock out the main disconnect switch according to safety protocols. Meanwhile, allow the system to cool to ambient temperature before beginning separator replacement.

Step 2: Separator Vessel Access

Carefully remove the separator vessel cover using appropriate tools while maintaining proper lifting technique. Then, inspect the vessel interior for oil contamination or debris requiring cleaning attention. Additionally, check all gasket surfaces for damage or wear that might affect proper sealing.

Step 3: Old Separator Removal

Extract the used separator element carefully to prevent media contamination from falling into the vessel. Next, inspect the separator for collapse or damage that might indicate system problems requiring correction. Furthermore, clean the vessel thoroughly using appropriate solvents to remove oil residue.

Step 4: New Separator Installation

Install the new Atlas Copco 1625481151 separator ensuring proper orientation according to airflow direction arrows. Moreover, apply a thin film of clean oil to the gasket surfaces to ensure optimal sealing performance. Tighten all connections to specification using 25-30 Nm torque values.

Step 5: System Commissioning

Reassemble the separator vessel and gradually pressurize the system while monitoring for leaks. Subsequently, start the compressor and observe oil carryover levels during initial operation cycles. Finally, verify proper separation efficiency by testing downstream air quality after 60 minutes of continuous operation.

User Feedback

Sarah Williams, Plant Maintenance Manager at Precision Electronics Manufacturing, shares her experience with Atlas Copco genuine oil separators: “Our facility operates six GA22 compressors supporting critical clean room environments where oil contamination absolutely cannot occur.

We previously experienced frequent oil carryover issues with aftermarket separators, resulting in contaminated products and costly production delays. After switching to genuine Atlas Copco 1625481151 separators eight months ago, our downstream oil content measurements consistently show <0.1 ppm residual oil.

The extended 4,000-hour service interval has significantly reduced our maintenance workload while improving system reliability. Previously, we replaced separators every 2,800 hours due to premature failure and efficiency degradation. Now our maintenance schedule aligns perfectly with other major service intervals.

Most importantly, we haven’t experienced any product contamination incidents since implementing genuine separators. The cost savings from eliminated scrap and rework far exceed the price difference compared to aftermarket alternatives. Our quality assurance team reports 98% improvement in compressed air purity testing results.”

Frequently Asked Questions

Q1: How often should I replace the oil separator in my Atlas Copco compressor?

Replace the separator every 4,000 operating hours or every two years, whichever occurs first. However, systems operating in dusty environments may require replacement at 3,000-hour intervals to maintain optimal performance.

Q2: What symptoms indicate a failing oil separator?

Common signs include increased oil carryover in compressed air, rising pressure differential across the separator, and visible oil downstream of the air treatment equipment. Monitor pressure drop and replace when it exceeds 7-8 PSI.

Q3: Can I clean and reuse an oil separator to extend its service life?

Oil separators use synthetic media that cannot effectively be cleaned or restored. Therefore, replacement with genuine Atlas Copco parts ensures optimal performance and maintains warranty coverage for your compressor system.

Q4: What happens if I operate with a collapsed or damaged separator?

A collapsed separator allows unfiltered oil to pass directly into the compressed air system, potentially causing downstream equipment damage and product contamination. Replace immediately upon discovery of separator failure.

Q5: Are there environmental benefits to using genuine Atlas Copco separators?

The extended 4,000-hour service interval reduces waste generation by 35% compared to shorter-life alternatives. Additionally, improved separation efficiency reduces oil consumption and minimizes environmental impact from oil disposal.

More Oil separators List

If you need other Atlas Copco air compressor oil separators, we provide more models in the table below or you can submit your requirements to us directly.

| Part Number | Part Name | Part-Number |

| 3001517300 | OIL SEPARATOR KIT | 3001-5173-00 |

| 3001531106 | OIL SEPARATOR KIT (A-D VESSEL) | 3001-5311-06 |

| 3001531107 | OIL SEPARATOR KIT (B VESSEL) | 3001-5311-07 |

| 3001531108 | OIL SEPARATOR KIT (C VESSEL) | 3001-5311-08 |

| 3001531109 | OIL SEPARATOR KIT (H VESSEL) | 3001-5311-09 |

| 3002600140 | OIL SEPARATOR KIT | 3002-6001-40 |

| 3002601530 | OIL SEPARATOR KIT | 3002-6015-30 |

| 3002601740 | OIL SEPARATOR KIT | 3002-6017-40 |

| 3002602100 | OIL SEPARATOR KIT | 3002-6021-00 |

| 3002603910 | XDF OIL SEPARATOR KIT | 3002-6039-10 |

| 3002603920 | XDF OIL SEPARATOR KIT | 3002-6039-20 |

| 3002603930 | XDF OIL SEPARATOR KIT | 3002-6039-30 |

| 3002605130 | OIL SEPARATOR ELEMENT KIT | 3002-6051-30 |

| 6221373150 | OIL SEPARATOR ELEMENT | 6221-3731-50 |

| 2204154150 | OIL SEPARATOR C80 BP BOXED | 2204-1541-50 |

| 2205105400 | OIL SEPARATOR JOINT | 2205-1054-00 |

| 2205105401 | OIL SEPARATOR JOINT | 2205-1054-01 |

| 2205105500 | OIL SEPARATOR PIPE | 2205-1055-00 |

| 2205105800 | OIL SEPARATOR SEAT | 2205-1058-00 |

| 2205114000 | OIL SEPARATOR SEAT | 2205-1140-00 |

| 2205116900 | OIL SEPARATOR JOINT | 2205-1169-00 |

| 2205117000 | OIL SEPARATOR PIPE | 2205-1170-00 |

| 2205117483 | OIL SEPARATOR | 2205-1174-83 |

| 2205118145 | OIL SEPARATOR SEAT | 2205-1181-45 |

| 2205118146 | OIL SEPARATOR ELEMENT | 2205-1181-46 |

| 2205176601 | OIL SEPARATOR | 2205-1766-01 |

| 2205195822 | RINGHT OIL SEPARATOR | 2205-1958-22 |

| 2911016000 | OIL SEPARATOR KIT | 2911-0160-00 |

| 2911014801 | OIL SEPARATOR | 2911-0148-01 |

| 2911011701 | OIL SEPARATOR | 2911-0117-01 |

| 2911011601 | OIL SEPARATOR | 2911-0116-01 |

| 2911011201 | OIL SEPARATOR | 2911-0112-01 |

| 2906075300 | OIL SEPARATOR KIT GA | 2906-0753-00 |

| 2906020200 | OIL SEPARATOR | 2906-0202-00 |

| 2903087100 | OIL SEPARATOR | 2903-0871-00 |

| 2903062301 | OIL SEPARATOR | 2903-0623-01 |

| 2903035101 | OIL SEPARATOR | 2903-0351-01 |

| 2903024500 | OIL SEPARATOR | 2903-0245-00 |

| 2902012500 | OIL SEPARATOR | 2902-0125-00 |

| 2901196400 | KIT OIL SEPARATOR | 2901-1964-00 |

| 2901196300 | KIT OIL SEPARATOR | 2901-1963-00 |

| 2901164300 | OIL SEPARATOR | 2901-1643-00 |

| 2901162610 | OIL SEPARATOR KIT GA | 2901-1626-10 |

| 2901162600 | OIL SEPARATOR KIT | 2901-1626-00 |

| 2901138900 | OIL SEPARATOR KIT | 2901-1389-00 |

| 2901071302 | OIL SEPARATOR KIT GA | 2901-0713-02 |

| 2901056602 | OIL SEPARATOR KIT GA | 2901-0566-02 |

| 2235410267 | OIL SEPARATOR ASSY | 2235-4102-67 |

| 2205406516 | OIL SEPARATOR ELEMEN | 2205-4065-16 |

| 2901052300 | AIR-OIL-SEPARATOR KI | 2901-0523-00 |

Protect Your Compressed Air Investment

Don’t compromise your critical compressed air quality with inferior separation components. The genuine Atlas Copco 1625481151=1625481101 Oil Separator from authorized supplier Seadweer ensures maximum performance and reliability.

Contact Seadweer now for competitive pricing on genuine Atlas Copco oil separators. Furthermore, our experienced technical team provides comprehensive support for maintenance planning and system optimization. Invest in authentic components that deliver proven performance and uncompromising air quality.

Choose genuine Atlas Copco separators – your production quality depends on it.

Anonymous –

This oil separator from seadweer arrived quickly and performs perfectly.

The quality is undeniable, ensuring optimal compressor efficiency. Their excellent service means we’ll definitely be buying again and look forward to a long-term partnership.

Anonymous_buyer –

Perfect fit, works great!

Perfect fit, works great! My compressor is running smoothly again. Highly recommend this genuine part.