The air end stands as the undeniable heart of any screw air compressor, driving the essential process of converting ambient air into pressurized energy. Its precision, efficiency, and overall reliability directly determine the compressor’s performance, energy consumption, and operational lifespan. Among these critical components, the Genuine Atlas Copco ATSL-1651E Air End, identified by part number 2236050200, represents a benchmark of engineering excellence. This specific air end delivers optimal compressed air output for designated 3.7Kw Atlas Copco compressor models, reliably reaching pressures up to 10 Bar.

When your compressor’s air end signals the need for service or replacement due to wear, age, or malfunction, installing a genuine unit is not merely an option; it is an absolute necessity for protecting your investment and ensuring uninterrupted productivity. For businesses seeking this authentic, high-precision air end assembly, Seadweer stands as a professional and trusted supplier specializing in genuine Atlas Copco compressor parts. Consequently, choosing Seadweer ensures you acquire an air end manufactured to the exact specifications and uncompromising quality standards set by Atlas Copco.

Contents

- 1 Why the Air End is Indispensable

- 2 Introducing the 2236050200 Air End

- 3 Key Features and Benefits of the 2236050200 Air End

- 4 Representative Technical Specifications

- 5 Installation Steps for Atlas Copco 2236050200 Air End

- 6 Seadwee: Your Authentic Source for Air End

- 7 Frequently Asked Questions (FAQs)

- 8 Conclusion

- 9 Atlas Copco Air End Matching Table

- 10 Inquiry Now

Why the Air End is Indispensable

The air end acts as the compressor’s primary engine, literally driving the air compression process. Within its robust housing, precisely machined male and female rotors intermesh, drawing in air from the inlet and progressively reducing its volume, thereby increasing its pressure. This complex mechanical interaction, typically aided by lubricating oil for sealing, cooling, and noise reduction in oil-flooded designs, dictates the compressor’s air delivery capacity and its energy efficiency. Any wear, misalignment, or damage to the rotors, their bearings, or the housing significantly compromises performance. This leads to increased power consumption, reduced air output, and eventually results in costly operational failure. Therefore, the air end’s optimal health remains paramount for consistent air supply and cost-effective operation.

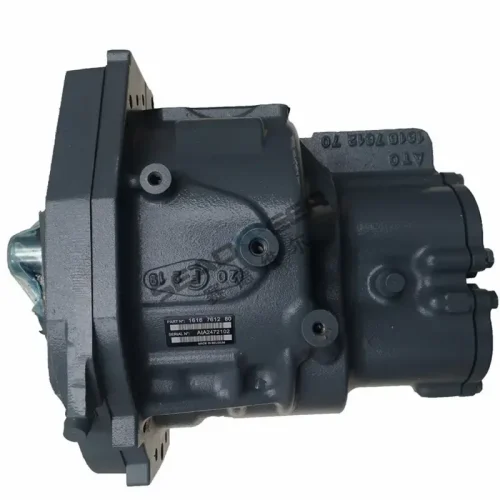

Introducing the 2236050200 Air End

The Genuine Atlas Copco ATSL-1651E Air End, identified by part number 2236050200, is a complete, factory-calibrated assembly specifically designed for seamless integration into designated Atlas Copco screw compressors. This part number and the “ATSL-1651E” designation signify a unit engineered to pair perfectly with a 3.7Kw motor, reliably producing compressed air up to 10 Bar. Atlas Copco manufactures this air end with exceptional attention to detail, ensuring minimal internal leakage and maximum volumetric efficiency. Each ATSL-1651E air end undergoes rigorous testing and balancing processes, which guarantee smooth rotation and minimal vibration during operation. As an authentic component, the 2236050200 air end restores the compressor’s original performance characteristics, including its designed air flow rate and specific power, which is vital for long-term operational success, especially for units in its power class.

Key Features and Benefits of the 2236050200 Air End

Opting for the Genuine Atlas Copco ATSL-1651E Air End 2236050200 delivers a range of significant benefits that directly impact your compressor’s long-term performance and operational costs. Firstly, its precision-machined rotor profiles ensure optimal air compression, translating into higher air output for less energy input. This directly contributes to substantial electricity savings over the air end’s lifespan. Secondly, Atlas Copco utilizes superior materials and advanced manufacturing techniques, which results in exceptional durability and wear resistance, significantly extending the unit’s service life. Furthermore, the air end’s precisely balanced rotors and high-quality bearings minimize vibration and noise, promoting smoother operation and reducing stress on other compressor components. Ultimately, investing in this genuine air end secures your compressor’s reliability, maximizes its operational efficiency, and ensures long-term cost savings for your 3.7Kw system.

Representative Technical Specifications

The Genuine Atlas Copco ATSL-1651E Air End 2236050200 adheres to a specific set of highly precise technical parameters that define its performance capabilities, dimensions, and material composition. These specifications ensure it functions flawlessly within the compressor system and delivers the expected air output and efficiency at its rated 3.7Kw motor power and 10 Bar pressure. While the precise, detailed engineering specifications are proprietary to Atlas Copco, the table below outlines representative technical characteristics typical of a high-quality screw air end designed for industrial applications in this power class. These properties contribute directly to its efficiency, durability, and operational limits.

| Feature | Genuine Atlas Copco ATSL-1651E Air End 2236050200 | Non-Genuine Alternatives |

| Rotor Profile | Precisely engineered, optimized for efficiency | Often inferior or less efficient profiles |

| Material Quality | High-grade, specialized alloys for durability | Inferior or inconsistent materials, prone to wear |

| Bearing Precision | Factory-installed, high-precision, balanced bearings | Lower quality bearings, shorter lifespan |

| Balancing | Meticulously balanced to minimize vibration | Often poorly balanced, causing excessive vibration |

| Volumetric Efficiency | Optimized for maximum air output per kW | Lower efficiency, leading to higher energy consumption |

| Lifespan | Engineered for extended operational life | Significantly shorter lifespan, rapid degradation |

| Fit & Alignment | Perfect, seamless integration | May require modifications, causing stress or misalignment |

| Warranty | Maintains equipment warranty (check terms) | Can void equipment warranty, no manufacturer support |

| Reliability | Reduces risk of catastrophic failure | Higher risk of unexpected breakdown and costly repairs |

Note: These parameters are representative. The precise technical specifications for Atlas Copco ATSL-1651E Air End part number 2236050200 are defined by Atlas Copco’s engineering for its specific application.

Installation Steps for Atlas Copco 2236050200 Air End

Replacing an Atlas Copco ATSL-1651E Air End 2236050200 is an extremely complex and highly specialized task. It requires extensive technical expertise, specialized tools, and strict adherence to safety protocols. Incorrect installation or misalignment can lead to immediate and catastrophic failure of the compressor, substantial damage, or severe safety risks. It is absolutely imperative that this procedure be performed only by highly qualified, certified compressor technicians or authorized service personnel.

General Installation Steps (Requires Specialized Expertise & Tools):

1.Critical Safety Protocols:

Crucially, ensure the compressor is fully de-energized, isolated from all power sources, and properly locked out/tagged out according to established safety procedures. Relieve all internal pressure from the system and allow components to cool completely. Drain all compressor oil into an appropriate container.

2.Disassemble Surrounding Components:

Carefully remove all connecting pipes, hoses, electrical wiring, and structural components that impede access to the air end. This often includes removing the motor, oil separator tank, coolers, and control panels. Document every step, taking numerous photographs and labeling all connections for accurate reassembly.

3.Support and Remove Old Air End:

Use appropriate lifting equipment and slings (if necessary, given the size) to safely support the weight of the air end. Disconnect all remaining mounting bolts and carefully remove the old 2236050200 ATSL-1651E air end from the compressor frame. Exercise extreme caution during removal to prevent injury or damage.

4.Inspect Frame and Connections:

Thoroughly clean and inspect the compressor frame, motor coupling, and all connecting interfaces for any damage, wear, or debris. Address any issues before proceeding with the new air end installation.

5.Prepare New Air End:

Unpack the new, Genuine Atlas Copco ATSL-1651E Air End 2236050200. Ensure all protective caps are removed and inspect the air end for any transit damage. Apply a thin film of clean compressor oil to the rotor tips, bearing surfaces, and seals as required by the manual to aid in smooth startup.

6.Install New Air End:

Carefully position the new air end onto the compressor frame. Align it precisely with the motor coupling and mounting points. Secure all mounting bolts to the specified torque values, following a strict crisscross tightening sequence.

7.Align and Connect:

Reconnect the motor to the air end, ensuring precise coupling alignment. Reconnect all oil lines, air inlet/outlet piping, and sensor wiring. Replace all gaskets, O-rings, and seals with new, genuine parts during reassembly to ensure leak-free operation.

8.Lubrication and Pre-Checks:

Refill the compressor with the correct type and quantity of genuine Atlas Copco compressor oil. Perform a thorough pre-start inspection, manually rotating the air end (if possible and safe) to ensure smooth, unhindered movement.

9.Commissioning and Testing:

Restore power to the compressor. Perform a controlled initial startup and commissioning procedure as per the manufacturer’s manual. Monitor all operational parameters (pressure, temperature, vibration, noise) meticulously during initial operation. Conduct a thorough leak test on all connections.

Disclaimer: This guide is a simplified overview. Replacement of an Atlas Copco compressor air end is an extremely complex procedure requiring specialized tools, precise measurements, factory-level expertise, and extensive technical training. It must only be performed by certified and authorized Atlas Copco service technicians following all manufacturer guidelines and safety regulations. Attempting this without proper training can result in severe injury, catastrophic equipment damage, and voided warranties.

Seadwee: Your Authentic Source for Air End

When your compressor’s core component, the air end, requires replacement, selecting a trustworthy supplier remains paramount. Seadweer stands as a professional provider entirely dedicated to supplying genuine Atlas Copco air compressor parts. Their unwavering commitment to authenticity means every 2236050200 ATSL-1651E Air End you acquire from them is a product manufactured to Atlas Copco’s exact engineering specifications and undergoes rigorous factory quality control. Purchasing from Seadweer helps eliminate the inherent risks associated with non-genuine air ends. These risks include imprecise rotor profiles, inferior bearing quality, or improper balancing, which can lead to rapid wear, catastrophic failure, and substantial downtime. Therefore, partnering with Seadweer provides unwavering confidence in the quality, reliability, and long-term performance of this crucial compressor component.

Frequently Asked Questions (FAQs)

Q1: What is the Atlas Copco ATSL-1651E Air End 2236050200? A1: This is the core compression element of an Atlas Copco screw compressor, specifically designed to pair with a 3.7Kw motor and produce air up to 10 Bar. It contains precisely intermeshing rotors that compress air.

Q2: Why is it crucial to use a genuine 2236050200 ATSL-1651E Air End? A2: A genuine air end guarantees precise rotor profiles, high efficiency, durable materials, correct balancing, and a perfect fit. These qualities ensure optimal energy consumption, reliability, extended lifespan, and maintain your compressor’s warranty.

Q3: Which Atlas Copco compressor models are compatible with this air end? A3: The 2236050200 ATSL-1651E Air End is compatible with specific 3.7Kw, 10 Bar models within Atlas Copco’s G, GX, and smaller GA series screw compressors. Always verify compatibility using your compressor’s serial number.

Q4: Can I install the air end myself? A4: Absolutely not. Replacing a compressor air end is an extremely complex and specialized procedure requiring highly trained, certified technicians, specialized tools, and precise alignment. Incorrect installation can cause catastrophic damage and poses severe safety risks.

Q5: How does a genuine air end improve energy efficiency for a 3.7Kw compressor? A5: Genuine Atlas Copco air ends feature optimized rotor profiles and precision manufacturing that minimize internal air leakage and friction. This design ensures maximum air output for every unit of energy consumed, leading to significant electricity savings, especially crucial for smaller power ranges.

Conclusion

The Genuine Atlas Copco ATSL-1651E Air End 2236050200 stands as the indispensable heart of your compressor, driving its performance, efficiency, and reliability. Investing in this authentic, precision-engineered component ensures your 3.7Kw, 10 Bar compressor operates at its peak, delivering consistent air output with optimal energy consumption. By choosing a professional supplier like Seadweer, you guarantee the authenticity and uncompromising quality of this critical assembly, safeguarding your investment and securing the long-term health of your air compression system. Trusting genuine parts for the very core of your machine ultimately translates to maximum uptime and superior operational value.

Atlas Copco Air End Matching Table

| Brand | PN | NEW PN | Application | Motor Model NO. | Drive Mode |

| AtlasCopco | 2989015800 | 2989015800=1616646680 | GA30-45+50VSD | K25 | |

| AtlasCopco | 1616738280 | 1616738290 | GA18 ,GA26VSD+,GA22,GA26,GA30 | OIS I-01 C90 | Belt Driven |

| 1616738291 | |||||

| AtlasCopco | 1616714681 | 1616714682-1616714692 | XAXS600/LUY160-17 | C146 | Direct Driven |

| AtlasCopco | 1616706682 | 1616706690 | G110.G132,G160,G200,G250,GA110,GA132,GA160,GA200,GA250 | C242 | |

| 1616706692 | |||||

| AtlasCopco | 1616646680 | 2989015800 | GA30-45+50VSD | C106 | Belt Driven |

| AtlasCopco | 1616578982 | 2989015401 | GA55+,GA75,GA90,GA110 | C77-C90 | Direct Driven |

| AtlasCopco | 2236050100 | 2236050200 | GX1-2 | ATSL-165E | Belt Driven |

| AtlasCopco | 1616765180 | 1616765190 | C80 | Belt Driven | |

| AtlasCopco | 1616761280 | 1616761290 | XRVS1000 | C146 | Belt Driven |

| AtlasCopco | 1616757780 | 1616757790 | LU30-45 | C90 | Belt Driven |

| AtlasCopco | 1616757580 | 1616757590 | GA355-GA500 | C242 (New) | Direct Driven |

| AtlasCopco | 1616754080 | 1616754090 | GA355-500 | C242 | Direct Driven |

| AtlasCopco | 1616753582 | 1616753592 | C55 F09 | ||

| AtlasCopco | 1616753580 | 1616753590 | C55 F09 | Belt Driven | |

| AtlasCopco | 1616679281 | 1616747281 | ZR/ZT | C242 (New) | Direct Driven |

| AtlasCopco | 1616740980 | 1616740990 | GA110-GA132 | C146 | Direct Driven |

| AtlasCopco | 1616740881 | 1616740891 | C111 | Belt Driven | |

| AtlasCopco | 1616734582 | 1616734592 | G110.G132,G160,G200,G250,GA110,GA132,GA160,GA200,GA250 | C190 | Direct Driven |

| AtlasCopco | 1616734581 | 1616734591 | G110.G132,G160,G200,G250,GA110,GA132,GA160GA200 GA250 BLT160-275 | C190 | |

| AtlasCopco | 1616728180 | 1616728190 | GA37+GA75 | C111 | Belt Driven |

| AtlasCopco | 1616727181 | 1616727381 | Element HPT2 | ||

| AtlasCopco | 1616725880 | 1616725890 | |||

| AtlasCopco | 1616725781 | 1616725791 | OIS-N-02 | ||

| AtlasCopco | 1616528881 | 1616725691 | GA132 | C168 | |

| AtlasCopco | 1616725681 | 1616725691 | GA110/GA1320 /GA160/GA200/GA250/GA315 | C168 | Direct Driven |

| AtlasCopco | 1616719480 | 1616719490 | XAS97-185 | K-38 | Direct Driven |

| AtlasCopco | 1616714683 | 1616714693 | GA55+-75+-90/GA90VSD | 0IS-C146 | Belt Driven |

| AtlasCopco | 1616710380 | 1616710390 | GX2-5 | OLS D-11 C40 | Belt Driven |

| AtlasCopco | 1616671280 | 1616671290 | GA 15、GA 18、GA 22,etc | OIS H-06 | |

| AtlasCopco | 1616657583 | 1616657593 | GA5-GA11C | 0IS F-05 C55 | Belt Driven |

| AtlasCopco | 1616626081 | 1616626090 | Drive Mode | ||

| AtlasCopco | 1616580381 | ZR400VSD,ZR500VSD,etc | OFS K-21 | ||

| AtlasCopco | 1616590481 | ZR/ZT250 | OFS M-21 | ||

| AtlasCopco | 1616585181 | ZR/ZT 90-160VSD | OFS G-21 | ||

| AtlasCopco | 1616585187 | ZR/ZT | OFS G-27 | ||

| AtlasCopco | 2989015900 | XRVS1000 | C106 | Belt Driven | |

| AtlasCopco | 1616741883 | SF6+ | Belt Driven | ||

| AtlasCopco | 1616734580 | GA160 | |||

| AtlasCopco | 1616528850 | GA110,GA132,GA160 | C168 | ||

| AtlasCopco | 1616547081 | ||||

| AtlasCopco | 1616555101 | ||||

| AtlasCopco | 1616590482 | ||||

| AtlasCopco | 1616601080 | ||||

| AtlasCopco | 1616635681 | OFS Q-21 | |||

| AtlasCopco | 1616651280 | ||||

| AtlasCopco | 1616651283 | ||||

| AtlasCopco | 1616657380 | ||||

| AtlasCopco | 1616657580 | ||||

| AtlasCopco | 1616657590 | ||||

| AtlasCopco | 1616677081 | OFS E-21 | |||

| AtlasCopco | 1616710781 HP | ||||

| 1616711781 LP | |||||

| AtlasCopco | 1616719490 | ||||

| AtlasCopco | 1616724890 | C106 OMCO | |||

| AtlasCopco | 1616725790 | ||||

| AtlasCopco | 1616734590 | ||||

| AtlasCopco | 1616747590 | ||||

| AtlasCopco | 1616772590 | ||||

| AtlasCopco | 1616774591 | C67 | Belt Driven | ||

| 2236050000 | ATSL-140 | Belt Driven | |||

| AtlasCopco | 2989012200 | ||||

| AtlasCopco | 2989014400 | ||||

| AtlasCopco | 2989014500 | ||||

| AtlasCopco | 2989015401 | ||||

| AtlasCopco | 2989015700 |

Anonymous_Buyer –

Quality matters!

Rebuilt our Atlas Copco GX11 air rcompressor with this 2236050200 air end – runs like new! 20% quieter, 15% better airflow. Quality matters!