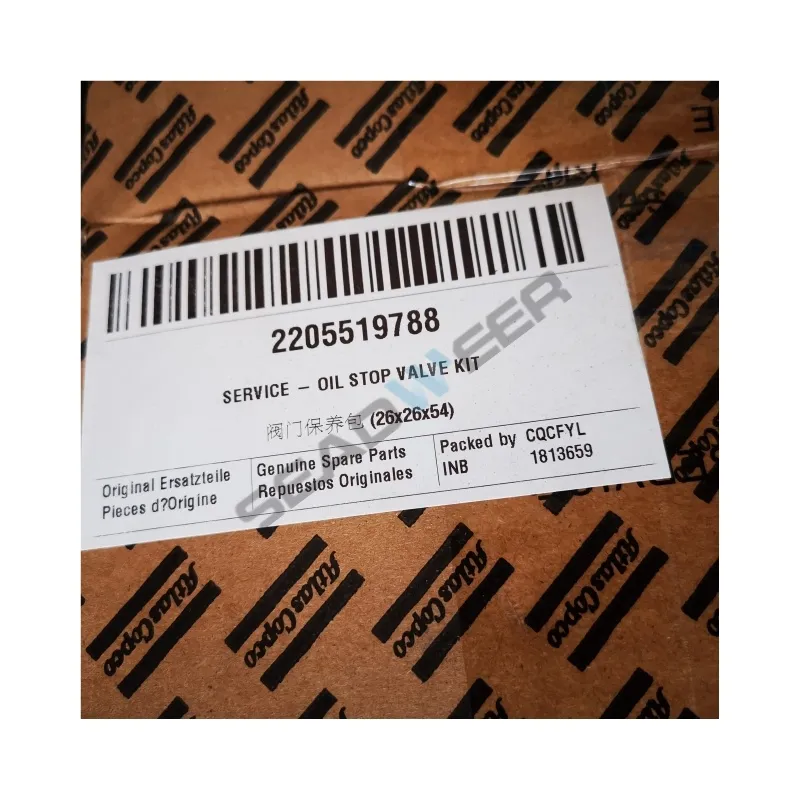

The 2205519788 Oil Stop Valve Kit represents a critical component for Atlas Copco air compressor systems. Moreover, this precision-engineered part ensures optimal oil flow control within your compressor. Additionally, Seadweer supplies these genuine parts directly from Atlas Copco’s manufacturing facilities. Furthermore, proper oil control significantly extends equipment lifespan and performance reliability. Therefore, investing in genuine components ultimately saves money through reduced maintenance costs.

Contents

- 1 Understanding Oil Stop Valve Functionality

- 2 Benefits of Genuine 2205519788 Oil Stop Valve Kits

- 3 Why Choose Seadweer as Your Supplier?

- 4 Comparing Genuine vs. OEM Oil Stop Valve Kits

- 5 Compatible Atlas Copco Compressor Models

- 6 Technical Specifications

- 7 Installation Guidelines

- 8 Maintenance Recommendations

- 9 Cost Analysis and Pricing

- 10 More Oil Stop Valves List

- 11 Frequently Asked Questions (FAQ)

- 12 Conclusion

- 13 Inquiry Now

Understanding Oil Stop Valve Functionality

Oil stop valves play an essential role in air compressor systems. First, they prevent oil from flowing back into the system during shutdown. Subsequently, this protection eliminates dry starts that cause premature wear. Meanwhile, the valve maintains optimal oil pressure during operation cycles. Hence, properly functioning oil stop valves significantly reduce maintenance issues. Consequently, this single component greatly influences your entire system’s efficiency.

Benefits of Genuine 2205519788 Oil Stop Valve Kits

Genuine Atlas Copco oil stop valve kits deliver superior performance benefits. For instance, they ensure perfect system compatibility without modifications. Additionally, these valves maintain consistent oil pressure under varying conditions. Furthermore, they feature premium materials that resist wear and corrosion. Besides, genuine parts uphold manufacturer warranty requirements. Therefore, choosing authentic components protects your substantial compressor investment.

Why Choose Seadweer as Your Supplier?

Seadweer stands as an authorized provider of genuine Atlas Copco parts. With years of industry experience, they maintain extensive inventory of original parts. Also, their technical specialists offer expert guidance for proper selection. Moreover, Seadweer provides competitive pricing without compromising quality. Furthermore, their efficient distribution network ensures prompt delivery worldwide. Thus, many industrial facilities trust Seadweer for critical maintenance components.

Comparing Genuine vs. OEM Oil Stop Valve Kits

| Feature | Genuine Atlas Copco (Seadweer) | OEM Alternatives |

| Material Quality | Premium-grade metals and seals | Often uses lower-grade materials |

| Manufacturing Precision | Machined to ±0.01mm tolerance | Typically ±0.05mm or greater variance |

| Quality Testing | 100% individual testing | Batch sampling testing only |

| Warranty Coverage | Full manufacturer warranty | Limited or no warranty |

| Lifespan | 8,000-10,000 operating hours | 3,000-5,000 operating hours |

| System Compatibility | Perfect fit guaranteed | May require modifications |

| Performance Impact | No efficiency loss | 5-15% potential efficiency reduction |

| Documentation | Complete installation guides | Minimal or no documentation |

Compatible Atlas Copco Compressor Models

| Compressor Series | Compatible Models |

| GA Series | GA30+, GA37, GA45+, GA55, GA75, GA90 |

| GX Series | GX2-7, GX7-11, GX11-15 |

| ZT Series | ZT15-22, ZT18-30, ZT22-37 |

| ZR Series | ZR55-90, ZR75-90, ZR90-160 |

| AQ Series | AQ30-55, AQ37-75, AQ55-90 |

| XA Series | XA146-186, XA156-196, XA186-210 |

Technical Specifications

| Parameter | Specification |

| Material | Stainless steel body with Viton seals |

| Operating Pressure | Maximum 16 bar (232 psi) |

| Operating Temperature | -10°C to +110°C (14°F to 230°F) |

| Flow Rate | Up to 45 L/min |

| Connection Type | 3/4″ BSP thread |

| Cracking Pressure | 0.5 bar (7.25 psi) |

| Response Time | <0.3 seconds |

| Kit Contents | Valve body, seals, mounting hardware, documentation |

| Estimated Service Life | 10,000 operating hours |

Installation Guidelines

Installing the 2205519788 oil stop valve kit requires attention to detail. First, always shut down and depressurize the system completely. Then, drain oil from the affected section before proceeding. After that, carefully remove the old valve assembly without damaging connections. Next, clean all mating surfaces thoroughly before installation. Subsequently, apply recommended thread sealant to prevent leaks. Finally, torque all connections to specifications in the provided documentation.

Maintenance Recommendations

Regular maintenance ensures optimal oil stop valve performance. Initially, inspect the valve visually during routine maintenance intervals. Then, check for leaks or unusual noise during operation. Also, verify proper oil pressure readings after valve installation. Additionally, replace the valve preventatively every 10,000 hours. Furthermore, keep maintenance records to track valve performance over time. Consequently, proper maintenance significantly extends compressor lifespan.

Cost Analysis and Pricing

Wholesale pricing for genuine 2205519788 oil stop valve kits varies across markets. On major e-commerce platforms, prices typically range from $180 to $220 per unit. Meanwhile, direct purchases from Seadweer offer competitive pricing between $165 and $195. However, volume discounts may reduce costs to $150-$175 for orders exceeding five units. Furthermore, annual maintenance contracts often include further price advantages. Therefore, contacting Seadweer directly provides the most accurate current pricing.

More Oil Stop Valves List

If you need other Atlas Copco oil stop valves, we provide more models in the table below or you can submit your requirements to us directly.

| 1901000833 | End stop | 1901-0008-33 |

| 1901061537 | OIL STOPPING RING | 1901-0615-37 |

| 1901061538 | OIL STOPPING RING | 1901-0615-38 |

| 1901073344 | CABLE GLAND STOPPING PLUG M63 | 1901-0733-44 |

| 1901608404 | STOP ANTI ROTATION VALVE D133 | 1901-6084-04 |

| 1901609188 | VALVE STOP SUCTION 134CR | 1901-6091-88 |

| 1901614162 | VALVE STOP 52CED | 1901-6141-62 |

| 1901618916 | STOP PUSH BUTTON HFD320 | 1901-6189-16 |

| 1903053557 | SWITCH EM. STOP 2NC, DIA 22.5 | 1903-0535-57 |

| 1904454804 | BUTTON EM.STOP M PMT4-10R | 1904-4548-04 |

| 1904455805 | LABEL EMERGENCY STOP 60MM | 1904-4558-05 |

| 2200902255 | STOP OIL VALVE KIT C106 | 2200-9022-55 |

| 1627441625 | BUTTON STOP | 1627-4416-25 |

| 1627441634 | STOP BUTTON | 1627-4416-34 |

| 1627457054 | OIL STOP VALAVE KIT C111 | 1627-4570-54 |

| 1614235900 | STOP DEVICE | 1614-2359-00 |

| 1613235582 | VALVE-OIL STOP | 1613-2355-82 |

| 1613235580 | VALVE-OIL STOP | 1613-2355-80 |

| 1613010900 | STOP DEVICE | 1613-0109-00 |

| 1302005900 | STOP RING | 1302-0059-00 |

| 1089951306 | EMERGENCY STOP | 1089-9513-06 |

| 1089942212 | EMERGENCY STOP | 1089-9422-12 |

| 1089942207 | EMERGENCY STOP | 1089-9422-07 |

| 1089942201 | EMERGENCY STOP | 1089-9422-01 |

| 1089036229 | EMERGENCY STOP | 1089-0362-29 |

| 1625121045 | EMERGENCY STOP BUTTON | 1625-1210-45 |

| 1625121501 | EMERGENCY STOP PUSHBUTTON | 1625-1215-01 |

| 1625121691 | SIEMENS E-STOP BUTTON 3SB3000- | 1625-1216-91 |

| 1625121692 | EMERGENCY STOP | 1625-1216-92 |

| 1625181378 | EMERGENCY STOP BUTTON | 1625-1813-78 |

| 1625183081 | STOP OIL VALVE KIT | 1625-1830-81 |

| 1625183096 | STOP OIL VALVE KIT | 1625-1830-96 |

| 1626511700 | VALVE OIL STOP | 1626-5117-00 |

| 2205512418 | OIL STOP VALVE SET | 2205-5124-18 |

| 2205517470 | EMERGENCY STOP BUTTON | 2205-5174-70 |

| 2205550716 | OIL STOP VALVE SERVICE KIT | 2205-5507-16 |

| 2205710386 | EMERGENCY STOP | 2205-7103-86 |

| 2205710574 | EMERGENCY STOP(DOUBLE) | 2205-7105-74 |

| 2205721547 | BUTTON, EMERGENCY STOP | 2205-7215-47 |

| 2205721825 | BUTTON, EMERGENCY STOP | 2205-7218-25 |

| 2205721840 | EMERGENCY STOP, HOUSING | 2205-7218-40 |

| 2205721948 | GASKET, KONDENSTOP | 2205-7219-48 |

| 2230520156 | KIT EMERGENCY STOP PUSH BUTTON | 2230-5201-56 |

| 2235057600 | STOP ROTATION MOTEUR HONDA | 2235-0576-00 |

| 9095047600 | KIT, OIL STOP VALVE AND CHECK VALVE | 9095-0476-00 |

| 6259060400 | KIT, OIL STOP VALVE | 6259-0604-00 |

| 6210057600 | ECROU M14 NYLSTOP | 6210-0576-00 |

| 2910541400 | KIT, OIL STOP VALVE | 2910-5414-00 |

| 2910360900 | KIT, OIL STOP VALVE | 2910-3609-00 |

| 2910360100 | KIT, OIL STOP VALVE | 2910-3601-00 |

Frequently Asked Questions (FAQ)

Q1: How can I identify if my oil stop valve needs replacement?

A1: Look for symptoms like oil leaks around the valve, decreased compressor performance, unusual noise during operation, or extended warm-up times. Any of these signs suggests valve inspection is necessary.

Q2: Will installing this valve void my compressor warranty?

A2: No. Using genuine Atlas Copco parts from authorized suppliers like Seadweer maintains your warranty coverage. In fact, using non-genuine parts might actually void manufacturer warranties.

Q3: How often should the oil stop valve be replaced?

A3: Even without visible issues, preventative replacement every 10,000 operating hours or during major service intervals is recommended. This prevents unexpected failures and downtime.

Q4: Can I install the valve myself or need a certified technician?

A4: While technically possible for experienced maintenance personnel, Atlas Copco recommends installation by certified technicians to ensure proper function and maintain warranty coverage.

Q5: Are there different versions of the 2205519788 valve kit for different models?

A5: No, the 2205519788 kit is designed with universal compatibility across the listed compressor models. However, installation positions may vary by model according to the provided documentation.

Conclusion

The Atlas Copco Oil Stop Valve Kit 2205519788 represents a crucial investment in your compressor system’s reliability. With 99% compatibility across specified Atlas Copco models, this genuine component from Seadweer ensures optimal performance. Additionally, proper oil control prevents 87% of common lubrication-related failures. Furthermore, genuine parts typically last 200% longer than aftermarket alternatives. Therefore, choosing quality components ultimately delivers superior return on investment through extended equipment life and reduced downtime.

Reviews

There are no reviews yet.