Every modern air compressor relies on a sophisticated control system to manage its operation, monitor its status, and ensure safety. The controller panel serves as the user interface and the central processing unit for these vital functions. Specifically, the Atlas Copco Air Compressor Controller Panel part number 1900071101 is a key component in numerous oil-injected screw compressor models, acting as the indispensable “brain” that dictates how the machine runs. When this critical component requires replacement, whether due to age, damage, or malfunction, installing a genuine, authentic part is paramount for maintaining the compressor’s performance, reliability, and safety features. For businesses seeking the genuine 1900071101 Controller Panel, Seadweer stands as a professional and trustworthy supplier of genuine Atlas Copco parts. Therefore, choosing Seadweer ensures you acquire a controller panel manufactured to the exact specifications and quality standards required by Atlas Copco.

Contents

- 1 Why the Controller Panel is Essential for Your Compressor

- 2 Introducing the Atlas Copco 1900071101 Controller Panel

- 3 Key Features and Functions of the 1900071101 Panel

- 4 The Seadweer Advantage: Your Source for the Genuine 1900071101 Controller Panel

- 5 Genuine 1900071101 Panel vs. Other Alternatives

- 6 Compressors Using the 1900071101 Panel

- 7 Technical Specifications

- 8 Installation Steps for the 1900071101 Controller Panel

- 9 Why Choosing the Genuine 1900071101 Panel is Critical

- 10 Frequently Asked Questions (FAQs)

- 11 Conclusion

- 12 Inquiry Now

Why the Controller Panel is Essential for Your Compressor

The controller panel is arguably one of the most important parts of an air compressor. It is the primary interface through which operators interact with the machine, allowing them to start and stop it, adjust settings, and view operational data. More importantly, the controller constantly monitors vital parameters such as air pressure, oil temperature, and motor status using various sensors. Based on these readings, it manages the compressor’s load and unload cycles to meet air demand efficiently. Furthermore, the controller incorporates crucial safety logic, initiating automatic shutdowns in response to critical conditions like over-temperature or over-pressure, thereby protecting the compressor and preventing potentially hazardous situations. Consequently, a functional and reliable controller panel is fundamental to safe, efficient, and automated compressor operation.

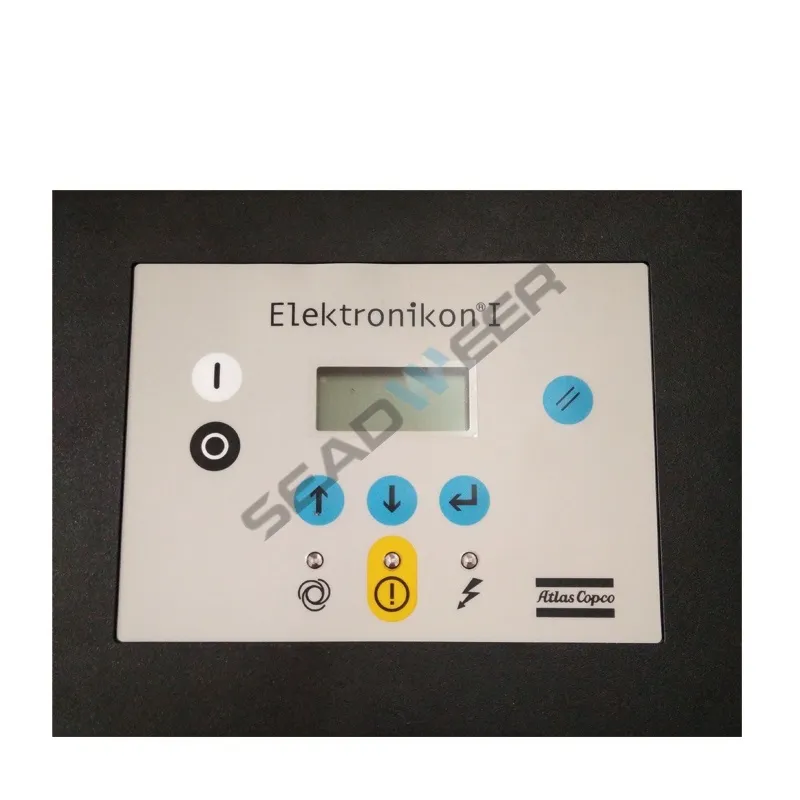

Introducing the Atlas Copco 1900071101 Controller Panel

The Atlas Copco 1900071101 Controller Panel is a genuine replacement component specifically designed for certain models within Atlas Copco’s range of oil-injected screw compressors. This particular part number identifies the complete control panel unit responsible for housing the operational buttons, display interface, and internal control electronics. It serves as the central hub where signals from various sensors are processed and commands are issued to the compressor’s motor, valves, and other components. As a genuine Atlas Copco part, the 1900071101 panel is manufactured to integrate seamlessly with the compressor’s existing wiring harness and control architecture. Thus, installing the authentic 1900071101 panel ensures full compatibility and restores the compressor’s original control capabilities and safety interlocks.

Key Features and Functions of the 1900071101 Panel

The 1900071101 Controller Panel offers the essential features necessary for managing and monitoring a standard oil-injected screw compressor. Operators typically utilize this panel for manual starting and stopping the compressor, including an emergency stop button for immediate shutdown in critical situations. The panel usually includes a display screen, which might be a simple digital display or an early generation graphical interface, showing key operating parameters such as outlet air pressure, oil temperature, and running hours. Furthermore, it provides visual indicators or alarm codes to alert operators to status changes, warnings, or faults. The controller’s internal programming manages automated functions like pressure-based start/stop and load/unload cycles, optimizing energy consumption based on air demand. Therefore, it provides the core intelligence and interface for reliable daily operation.

The Seadweer Advantage: Your Source for the Genuine 1900071101 Controller Panel

Acquiring a genuine Atlas Copco 1900071101 Controller Panel is paramount, and Seadweer specializes in providing genuine spare parts to ensure your compressor’s integrity. As a professional supplier dedicated to Atlas Copco products, Seadweer sources directly, guaranteeing that the 1900071101 panel you receive is an authentic component manufactured by or for Atlas Copco. This authenticity is especially critical for electronic components like control panels, where precise calibration, communication protocols, and built-in safety logic are vital. Choosing Seadweer helps you avoid the uncertainties and potential malfunctions associated with non-genuine panels, which may not fully replicate the original’s functionality or safety features. Consequently, partnering with Seadweer provides confidence that you are installing a reliable and fully compatible control panel.

Genuine 1900071101 Panel vs. Other Alternatives

Opting for a genuine Atlas Copco 1900071101 Controller Panel provides significant benefits compared to choosing non-genuine alternatives. Genuine panels guarantee perfect form, fit, and function, designed to connect precisely with the compressor’s existing hardware and wiring. Furthermore, they contain the correct software and calibration settings tailored to the specific compressor models they support, ensuring accurate monitoring and control.

| Feature | Genuine Atlas Copco 1900071101 Controller Panel | Other Alternatives |

| Fit & Form | Exact physical fit, direct replacement | May require modifications, poor alignment |

| Functionality | Full, intended control and monitoring features | May have limited or incorrect functions, missing features |

| Compatibility | Guaranteed communication with compressor sensors and components | Potential communication errors, system conflicts |

| Calibration | Pre-calibrated for compatible models | Calibration may be inaccurate or impossible |

| Safety Logic | Integrated, tested safety shutdown protocols | Safety features may be absent or unreliable |

| Reliability | Designed for long-term industrial use | Shorter lifespan, higher risk of premature failure |

| Warranty | Maintains equipment warranty (check terms) | Can void equipment warranty |

| Support | Supported via manufacturer/authorized channels | Little to no technical support available |

In summary, while non-genuine panels might appear similar externally, they often lack the internal precision, calibrated software, and robust build quality of the authentic 1900071101. This discrepancy can lead to unreliable operation, incorrect readings, failure of safety systems, and ultimately, increased downtime and repair costs.

Compressors Using the 1900071101 Panel

The Atlas Copco 1900071101 Controller Panel is designed for compatibility with specific series and models of Atlas Copco oil-injected screw compressors. This panel was typically used in certain generations of compressors before later control systems became standard. The table below lists representative Atlas Copco compressor series and examples of models within those series that may utilize the 1900071101 control panel. It is absolutely essential to verify compatibility for your specific compressor unit by consulting your machine’s technical documentation or serial number, as variations exist even within the same series depending on manufacturing date and specific configuration.

| Compressor Series | Typical Application Models (Representative) |

| GA Series | Many GA 11-30 kW, GA 30-45 kW models (older generations) |

| GX Series | Certain GX 7-11, GX 11-15 models |

| G Series | Some G 7-15, G 15-22 models |

Note: This table provides representative examples; specific compatibility with the 1900071101 part number must be verified based on your compressor’s full model, variant, and serial number, as specified in your documentation or by contacting a specialist.

Technical Specifications

The 1900071101 Controller Panel operates within specific technical parameters designed to interface correctly with the compressor’s electrical system and sensors. While precise, component-level specifications are proprietary to the manufacturer, the table below provides representative technical characteristics typically associated with this type of compressor control panel. These specifications ensure proper electrical connection, signal processing, and environmental resilience suitable for industrial settings.

| Parameter | Representative Characteristic / Value |

| Input Voltage | Typically 24 V DC (Control Voltage) |

| Power Consumption | Low Power |

| Display Type | Segmented LED or Basic LCD Display |

| Input/Output Points | Multiple Digital & Analog I/O points for sensors and actuators |

| Communication | Internal proprietary bus system |

| Operating Temp Range | Typically 0°C to +50°C |

| Protection Class | Often IP54 or IP65 (Front Panel) |

| Interface | Push Buttons, Emergency Stop Button |

Note: These parameters are representative. The precise technical specifications for Atlas Copco Controller Panel part number 1900071101 are defined by Atlas Copco.

Installation Steps for the 1900071101 Controller Panel

Replacing a compressor controller panel like the 1900071101 is a task that requires technical expertise and strict adherence to safety procedures. Incorrect installation can damage the new panel, the compressor, or pose a significant safety risk. It is strongly recommended that installation be performed by a qualified and certified compressor technician or electrician.

General Installation Steps (Requires Expertise):

- Prioritize Safety: Crucially, ensure the compressor’s main power supply is disconnected and locked out/tagged out according to proper safety procedures. Verify zero energy state.

- Access the Panel Area: Open the compressor’s control cabinet or enclosure to gain access to the existing controller panel and its wiring.

- Document Wiring: Before disconnecting anything, meticulously label all wires connected to the old panel using electrical markers or tape. Take clear photographs of the wiring configuration for reference.

- Disconnect Old Panel: Carefully disconnect all labeled wires from the terminals of the old controller panel. Remove any mounting screws or clips holding the old panel in place.

- Remove Old Panel: Gently remove the old 1900071101 controller panel from its mounting location.

- Install New Panel: Position the new, genuine 1900071101 controller panel in the mounting location. Secure it using the appropriate screws or clips.

- Reconnect Wiring: Reconnect all labeled wires to the corresponding terminals on the new panel, referring to your labels and photographs. Double-check every connection for correctness and security.

- Secure Enclosure: Close and secure the compressor’s control cabinet or enclosure.

- Restore Power & Test: Safely restore power to the compressor following correct procedures. Power on the machine and observe the new controller panel. Check for proper boot-up, display functionality, and responsiveness to button presses. Monitor the compressor during a test run, verifying that parameters are displayed correctly and safety shutdowns are active.

Disclaimer: This guide is for informational purposes only. Installation of electrical components on industrial machinery must only be performed by qualified and trained professionals following all local electrical codes and safety regulations. Failure to do so can result in severe injury, death, or equipment damage.

Why Choosing the Genuine 1900071101 Panel is Critical

The controller panel is not just a display; it’s the nerve center that manages complex operations and ensures the safety of your Atlas Copco compressor. Installing a genuine 1900071101 panel ensures perfect integration with the compressor’s existing sensors, wiring, and internal logic. This seamless communication is vital for accurate monitoring, efficient control cycles, and reliable activation of safety shutdown features when needed. Non-genuine panels often lack this precise integration, potentially leading to incorrect readings, operational inefficiencies, or, critically, failure of safety systems to function correctly in an emergency. Therefore, protecting your investment and ensuring the safety of your workplace depends heavily on using the authentic 1900071101 controller panel as specified by Atlas Copco.

Frequently Asked Questions (FAQs)

Q1: What does the Atlas Copco 1900071101 Controller Panel do?

A1: This control panel serves as the primary interface and brain for compatible Atlas Copco oil-injected screw compressors, managing operations like start/stop and load/unload, monitoring parameters like pressure and temperature, and implementing safety shutdowns.

Q2: Which compressor models are compatible with the 1900071101 Controller Panel?

A2: This panel is used in specific models within certain Atlas Copco series, typically older generations of GA and GX oil-injected screw compressors. Always verify compatibility using your compressor’s serial number and documentation.

Q3: Why is it important to buy a genuine 1900071101 Controller Panel?

A3: Genuine panels ensure perfect compatibility, correct calibration, reliable communication with sensors and components, and proper function of critical safety features, which non-genuine alternatives cannot guarantee.

Q4: Can I install the 1900071101 Controller Panel myself?

A4: Installation involves electrical connections and requires technical knowledge. It is strongly recommended that replacement of the 1900071101 Controller Panel be performed only by a qualified and certified compressor technician or electrician for safety and proper functionality.

Q5: Where can I purchase a genuine Atlas Copco 1900071101 Controller Panel?

A5: You can purchase genuine Atlas Copco parts, including the 1900071101 Controller Panel, from professional and trusted suppliers like Seadweer who specialize in authentic compressor components.

Conclusion

The Atlas Copco Air Compressor 1900071101 Controller Panel is a vital component, acting as the brain that ensures your compressor operates correctly, efficiently, and safely. Replacing a faulty panel with a genuine 1900071101 unit is essential for restoring full functionality and maintaining the integrity of your air compression system. By choosing a professional supplier like Seadweer, you guarantee that you receive an authentic, high-quality controller panel manufactured to Atlas Copco’s demanding standards, providing peace of mind and reliable performance. Investing in the genuine 1900071101 panel is an investment in the continued health and safe operation of your valuable compressor asset.

Anonymous –

Perfect upgrade for our GA90!

Perfect upgrade for our GA90! The 1900071101 controller delivers precise air management and zero faults after 8 months. Genuine Atlas Copco quality!

Seadweer –

Thank you very much for your trust and welcome to place an order next time.