Proper lubrication forms the cornerstone of reliable, efficient operation for any industrial screw air compressor. The lubricant acts as the machine’s essential lifeblood, diligently performing multiple critical functions: reducing friction, dissipating heat, sealing the air end, and safeguarding internal components from wear and corrosion. Among the vital consumables for these robust industrial workhorses, the Genuine Atlas Copco Air Compressor Oil 1630091900, supplied in a convenient 209-liter drum, offers unparalleled protection and sustained performance. This specialized lubricant ensures optimal efficiency, extends service life, and maintains the integrity of your Atlas Copco screw compressor fleet.

When it comes to maintaining your valuable equipment, choosing a genuine lubricant is not simply a recommendation; it is an absolute necessity for achieving peak operational efficiency and preventing costly, unscheduled downtime. For businesses requiring this authentic, high-performance compressor oil in bulk, Seadweer stands as a professional and trusted supplier specializing in genuine Atlas Copco compressor parts and consumables. Consequently, choosing Seadweer ensures you acquire a lubricant formulated to the exact specifications and uncompromising quality standards set by Atlas Copco.

Contents

- 1 Understanding Compressor Oil’s Vital Role

- 2 Introducing the Atlas Copco Air Compressor Oil 1630091900 (209L)

- 3 Key Features and Benefits

- 4 Genuine 1630091900 Lubricant vs. Non-Genuine Alternatives

- 5 Atlas Copco Screw Compressors Using This Lubricant

- 6 Lubricant Change Procedure

- 7 Frequently Asked Questions (FAQs)

- 8 Seadweer: Your Authentic Source for Genuine 1630091900 Lubricant

- 9 Conclusion

- 10 Lubricants Matching Table

- 11 Inquiry Now

Understanding Compressor Oil’s Vital Role

Within an oil-injected screw air compressor, the lubricant performs a multifaceted role under highly demanding conditions.

Firstly, it creates a crucial film between the intermeshing male and female rotors within the air end, effectively minimizing friction and preventing damaging metal-to-metal contact. This action directly reduces wear and tear, significantly extending the lifespan of the precision-engineered air end.

Secondly, the oil acts as a sealant, filling the clearances between the rotors and the casing, which maximizes volumetric efficiency and ensures consistent air delivery.

Furthermore, it actively absorbs and carries away the immense heat generated during the compression process, preventing thermal degradation of components and maintaining stable operating temperatures. Finally, the lubricant also plays a vital role in cleaning the internal system, suspending contaminants and transporting them to the oil filter for removal.

Therefore, the quality and specific formulation of the lubricant remain paramount for maintaining your screw compressor’s performance, energy efficiency, and longevity.

Introducing the Atlas Copco Air Compressor Oil 1630091900 (209L)

The Genuine Atlas Copco Air Compressor Oil 1630091900 is a high-performance, long-life lubricant meticulously formulated for the unique operational demands of Atlas Copco oil-flooded screw compressors. This lubricant is not merely a generic oil; it is a proprietary blend engineered to withstand the high temperatures, pressures, and shear forces characteristic of rotary screw compression. Its advanced composition ensures exceptional thermal and oxidative stability, resisting breakdown and sludge formation even under continuous, heavy-duty industrial operation. Furthermore, it incorporates specialized anti-wear additives that provide superior protection to critical internal components, particularly the air end bearings and rotors. This lubricant also offers excellent anti-foaming characteristics, which prevent air entrainment and ensure consistent lubrication. Packaged in a substantial 209-liter drum, it provides an economical solution for larger industrial facilities or those managing a fleet of Atlas Copco compressors, facilitating bulk procurement and efficient inventory management.

Key Features and Benefits

Opting for the Genuine Atlas Copco Air Compressor Oil 1630091900 delivers a range of significant benefits that directly impact your screw compressor’s operational costs and reliability. Firstly, its superior lubricity reduces friction within the air end, thereby minimizing energy consumption and increasing the compressor’s overall efficiency. Secondly, the lubricant’s excellent thermal and oxidative stability prevents premature degradation, extending service intervals and reducing the frequency of oil changes. This translates to fewer maintenance disruptions. Thirdly, powerful anti-wear additives provide robust protection to the air end, bearings, and other critical components, significantly extending component life and reducing maintenance expenses. Moreover, its effective anti-corrosion properties safeguard internal metal surfaces from rust and degradation, particularly important in humid operating environments. Ultimately, this genuine lubricant helps maintain optimal performance, reduces unexpected downtime, and protects your valuable compressor investment over the long term.

Genuine 1630091900 Lubricant vs. Non-Genuine Alternatives

Choosing the Genuine Atlas Copco Air Compressor Oil 1630091900 over non-genuine alternatives is a critical decision that profoundly impacts your screw compressor’s performance, lifespan, and overall operational costs. Non-genuine lubricants may offer a lower initial price, but their hidden costs often outweigh any perceived savings through reduced efficiency, increased maintenance, and potential damage to expensive components.

| Feature | Genuine Atlas Copco 1630091900 Lubricant | Non-Genuine Alternatives |

| Viscosity Stability | Maintains optimal viscosity across wide temperature range | Fluctuates, leading to poor lubrication at extremes |

| Oxidation Resistance | High resistance, minimizing sludge & acid formation | Poor resistance, leading to rapid degradation & deposits |

| Anti-Wear Additives | Precisely balanced for maximum component protection | Insufficient or incorrect additives, causing accelerated wear |

| Foaming Characteristics | Excellent anti-foaming properties, preventing air entrainment | Prone to foaming, reducing lubrication effectiveness |

| Sludge & Varnish | Minimizes deposits, ensuring clean internal components | Forms sludge and varnish, clogging passages and filters |

| Thermal Stability | Resists breakdown at high operating temperatures | Degrades prematurely, leading to increased oil changes |

| Material Compatibility | Formulated to protect Atlas Copco specific materials | May react negatively with seals, hoses, or internal coatings |

| Service Life | Engineered for specified extended drain intervals | Significantly shorter lifespan, requiring frequent changes |

| Warranty Impact | Maintains equipment warranty (check terms) | Can void equipment warranty, no manufacturer support |

This comparison clearly demonstrates that genuine lubricants are the result of extensive research, development, and stringent quality control processes. Non-genuine oils, conversely, often fall short in critical areas, risking premature wear, increased energy consumption, and ultimately, a higher total cost of ownership due to accelerated component degradation and unexpected downtime.

Atlas Copco Screw Compressors Using This Lubricant

The Atlas Copco Air Compressor Oil 1630091900 is specifically formulated and recommended for a wide range of Atlas Copco oil-flooded rotary screw air compressors. Its unique properties are designed to meet the demanding requirements of these advanced machines, ensuring optimal performance and longevity. The table below lists representative Atlas Copco screw compressor series and examples of models within those series that typically utilize this lubricant. However, to guarantee the correct lubricant for your exact compressor unit, it is absolutely essential to consult your machine’s technical documentation, operator’s manual, or specific part lists. Lubricant requirements can vary based on the specific model variant, operating conditions, or even the ambient temperature in your region.

| Compressor Series | Typical Application Models (Representative) |

| GA Series | GA 15-500 (Various models, check manual) |

| G Series | G 15-450 (Various models, check manual) |

| GX Series | GX 2-11 (Various models, check manual) |

| ZR/ZT (Oil-Flooded) | Older oil-flooded models (if applicable, verify) |

| VSD Series | GA VSD, G VSD (Specific variants, verify) |

Note: Always confirm the specific lubricant type and part number (1630091900) recommended for your Atlas Copco screw compressor model in its official manual or by consulting an authorized service provider. Using the wrong lubricant can void your warranty and damage your compressor.

Lubricant Change Procedure

Performing a regular lubricant change on your Atlas Copco screw compressor is a crucial maintenance task that ensures its longevity and peak performance. This procedure typically occurs at specified intervals as part of a preventive maintenance plan. Always refer to your specific compressor’s operator manual for detailed instructions and safety precautions. This general guide outlines the key steps involved when using a 209L drum of lubricant.

General Lubricant Change Steps (Requires Competence & Tools):

Prioritize Safety:

Crucially, ensure the compressor is fully shut down, de-energized, and isolated from all power sources. Properly lock out/tagged out the electrical supply. Relieve all internal pressure from the system by opening the air outlet valve or safety valve. Allow the compressor to cool down sufficiently to prevent burns from hot oil (but warm oil drains better).

Gather Supplies:

Have the new Genuine Atlas Copco Air Compressor Oil 1630091900 (209L drum), a suitable large-capacity drain pan or vacuum pump system, a clean pump for transferring oil from the drum, new oil filters, new air filters, and clean rags.

Drain Old Oil:

Locate the oil drain valve, typically at the bottom of the oil separator tank. Connect a hose to the drain valve and direct it to a large, appropriate waste oil collection container. Slowly open the drain valve and allow all the old lubricant to drain completely. Tilt the compressor slightly if possible to ensure full drainage.

Replace Oil Filter(s):

Once the oil has drained, remove the old oil filter(s) using a filter wrench. Clean the filter housing seating surface. Apply a thin film of new oil to the gasket of the new genuine Atlas Copco oil filter(s). Install the new filter(s) hand-tight, then tighten an additional 1/4 to 1/2 turn as per manufacturer guidelines.

Replace Air Filter(s) and Separator Element (if due):

While the system is open for oil change, it’s an opportune time to replace the air filter(s) and, if scheduled, the oil separator element. Follow the manual for these replacements.

Clean and Close Drain:

Once all the old oil has drained, clean the area around the drain valve. Close the drain valve securely.

Refill with New Lubricant:

Locate the oil fill port, usually on top of the oil separator tank. Using a clean pump and hose, carefully transfer the new Genuine Atlas Copco Air Compressor Oil 1630091900 from the 209L drum into the compressor. Fill to the ‘FULL’ or ‘MAX’ mark on the oil level indicator (sight glass). Do not overfill.

Initial Run and Check:

Close the fill cap. Run the compressor for a few minutes (e.g., 5-10 minutes) to circulate the new oil and fill the filters. Shut down the compressor, wait for pressure to relieve, and then recheck the oil level. Add more oil if necessary to reach the correct mark.

Dispose of Waste Oil:

Properly dispose of the old compressor lubricant at an authorized waste oil collection facility according to local regulations. Do not pour it down drains or onto the ground.

Disclaimer: This guide provides general steps. Always consult your specific Atlas Copco screw compressor’s operator manual for detailed instructions, precise oil capacity, specific safety protocols, and recommended lubricant change intervals. Lubricant changes should be performed by competent personnel.

Frequently Asked Questions (FAQs)

Q1: What is the primary purpose of Atlas Copco Air Compressor Oil 1630091900? A1: This lubricant is specifically formulated for Atlas Copco oil-flooded screw air compressors. It lubricates, cools, seals the air end, and protects internal components from wear, friction, and heat, ensuring efficient and reliable operation.

Q2: Why is it crucial to use genuine Atlas Copco compressor lubricant? A2: Genuine lubricants are precisely formulated to meet the exact specifications of Atlas Copco compressors. They offer superior performance, longer drain intervals, optimal protection against wear, and maintain your compressor’s warranty.

Q3: How often should I change the lubricant in my screw compressor? A3: The lubricant change interval for your screw compressor depends on the model, operating conditions, and the specific lubricant type. Always consult your Atlas Copco compressor’s operator manual for the recommended maintenance schedule.

Q4: Can I mix different types of compressor oils? A4: Absolutely not. Mixing different compressor oils, even those from the same manufacturer, can lead to unpredictable chemical reactions, sludge formation, reduced performance, and severe damage to your compressor. Always flush the system if changing oil types.

Q5: What are the benefits of purchasing the 209-liter drum of lubricant? A5: The 209-liter drum provides a cost-effective bulk solution for industrial facilities with multiple Atlas Copco compressors or those requiring frequent oil changes, minimizing procurement effort and potentially reducing per-liter cost.

Seadweer: Your Authentic Source for Genuine 1630091900 Lubricant

When the time comes to replenish your compressor’s vital fluids, selecting a trustworthy supplier is non-negotiable. Seadweer stands as a professional provider entirely dedicated to supplying genuine Atlas Copco air compressor parts and consumables. Their unwavering commitment to authenticity means every 1630091900 Air Compressor Oil (209L) you acquire from them is a product formulated to Atlas Copco’s exact engineering specifications and undergoes rigorous factory quality control. Purchasing from Seadweer helps eliminate the inherent risks associated with non-genuine lubricants. These risks include incorrect viscosity, poor thermal stability, insufficient or incompatible additive packages, or material incompatibility, which can lead to increased wear, sludge formation, premature component failure, and even catastrophic breakdown. Therefore, partnering with Seadweer provides unwavering confidence in the quality, reliability, and long-term protective capabilities of this crucial compressor lubricant.

Conclusion

The Genuine Atlas Copco Air Compressor Oil 1630091900 (209L drum) is an indispensable element for ensuring the long-term health, efficiency, and reliability of your Atlas Copco screw compressor fleet. Its specialized formulation provides superior protection against wear, heat, and degradation, directly contributing to lower operational costs and extended equipment life. By choosing this authentic lubricant from a professional supplier like Seadweer, you guarantee the purity and uncompromising quality of this vital consumable, safeguarding your investment and securing the uninterrupted performance of your air compression system. Trusting genuine consumables for the very core of your machine ultimately translates to maximum uptime and superior operational value.

Lubricants Matching Table

| PN/ID | Name | Capacity | Oil type | Compatibility | Service intervals |

| 2901170000 | Roto Xtend Duty Oil Specifications | 5 L plastic can | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 8 000 h or 2 years |

| 2901170100 | Roto Xtend Duty Oil Specifications | 20 L plastic can | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 8 000 h or 2 years |

| 2901170200 | Roto Xtend Duty Oil Specifications | 209 L metal drum | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 8 000 h or 2 years |

| 2901170300 | Roto Xtend Duty Oil Specifications | 1000 L ECO container | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 8 000 h or 2 years |

| 1630114600 | Roto Inject NDURANCE Oil Specifications | 5 L plastic can | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at mild ambient conditions |

| 1630091800 | Roto Inject NDURANCE Oil Specifications | 20 L plastic can | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at mild ambient conditions |

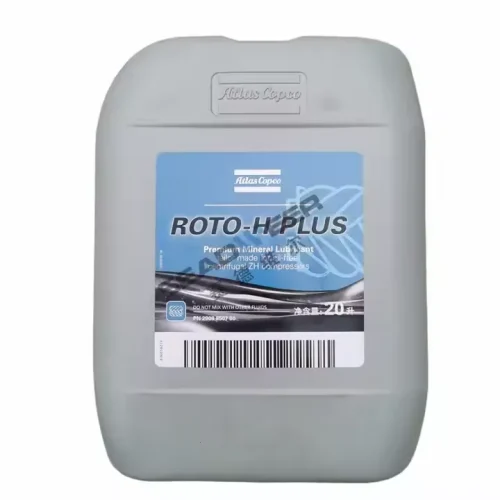

| 1630091900 | Roto Inject NDURANCE Oil Specifications | 209 L metal drum | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at mild ambient conditions |

| 1630144200 | Roto Inject NDURANCE Oil Specifications | 1000 L ECO container | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at mild ambient conditions |

| 2908850300 | Roto Z Oil Specifications | 5 L plastic can | Mineral based oil with tailored additive pack | ZR, ZT, ZA, ZE compressors | All conditions 8 000 h < 55 kw 16 000 h > 55 kw |

| 2908850101 | Roto Z Oil Specifications | 20 L plastic can | Mineral based oil with tailored additive pack | ZR, ZT, ZA, ZE compressors | All conditions 8 000 h < 55 kw 16 000 h > 55 kw |

| 2908850000 | Roto Z Oil Specifications | 209 L metal drum | Mineral based oil with tailored additive pack | ZR, ZT, ZA, ZE compressors | All conditions 8 000 h < 55 kw 16 000 h > 55 kw |

| 1630204105 | Roto Synthetic ULTRA Oil Specifications | 5 L plastic can | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 4 000 h or 2 year |

| 1630204120 | Roto Synthetic ULTRA Oil Specifications | 20 L plastic can | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 4 000 h or 2 year |

| 1630204129 | Roto Synthetic ULTRA Oil Specifications | 209 L metal drum | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 4 000 h or 2 year |

| 1630204100 | Roto Synthetic ULTRA Oil Specifications | 1000 L ECO container | Engineered synthetic based lubricant | GA – GX – GN – GR compressors | 4 000 h or 2 year |

| 1630083300 | Roto Synthetic Foodgrade Oil Specifications | 5 L plastic can | Synthetic base lubricant, specifically engineered for Food & Beverages, Pharmaceutical applications and its packing. | GA – GX compressors | 4 000 h or 1 year at reference conditions |

| 1630054200 | Roto Synthetic Foodgrade Oil Specifications | 20 L plastic can | Synthetic base lubricant, specifically engineered for Food & Beverages, Pharmaceutical applications and its packing. | GA – GX compressors | 4 000 h or 1 year at reference conditions |

| 1830023405 | Roto Synthetic Foodgrade Ultra Oil Specifications | 5 L plastic can | Synthetic based lubricant for Food & Beverages | GA – GX compressors | 4000 h or 2 years at demanding ambient conditions |

| 1830023406 | Roto Synthetic Foodgrade Ultra Oil Specifications | 20 L plastic can | Synthetic based lubricant for Food & Beverages | GA – GX compressors | 4000 h or 2 years at demanding ambient conditions |

| 1630205705 | Roto Z Foodgrade Oil Specifications | 5 L plastic can | Semi-synthetic based oil with tailored additive pack | ZR, ZT, ZA, ZE compressors | 4 000 h < 55 kw , 8 000 h > 55 kw (Or 2 years) |

| 1630205720 | Roto Z Foodgrade Oil Specifications | 20 L plastic can | Semi-synthetic based oil with tailored additive pack | ZR, ZT, ZA, ZE compressors | 4 000 h < 55 kw , 8 000 h > 55 kw (Or 2 years) |

| 2901024501 | Roto-Inject Fluid | 5 L plastic can | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at reference conditions |

| 2901052200 | Roto-Inject Fluid | 20 L plastic can | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at reference conditions |

| 2901004501 | Roto-Inject Fluid | 209 L metal drum | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at reference conditions |

| 2901004510 | Roto-Inject Fluid | 1000 L ECO container | Mineral based lubricant | GA – GX compressors | 4 000 h or 1 year at reference conditions |

Anonymous_Buyer –

We've seen remarkable improvements!

After switching to Atlas Copco 1630091900 oil in our GA75+, we’ve seen remarkable improvements! The compressor now runs 12°C cooler, extends service intervals by 300 hours, and maintains perfect viscosity even after 4,000 hours of continuous operation. Unlike generic oils that degraded after 2,000 hours, this genuine oil protects bearings significantly better – we measured 35% less wear in our last inspection. The anti-foaming properties eliminated our air-end noise issues completely. For just 15% higher cost than off-brands, we’re getting 50% longer oil life and 20% energy savings. Absolute must-have for serious compressor operators!