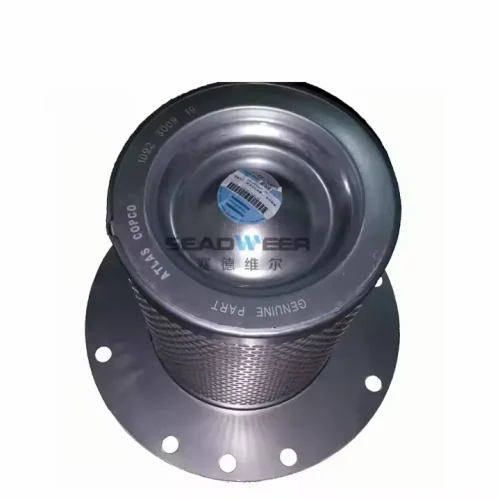

Achieving high-quality compressed air requires effective filtration. After the compressor generates air, pipeline filters remove remaining contaminants. The 1624104104 Pipeline Filter is a crucial component in this process. It ensures clean air reaches your downstream equipment. Consequently, using a genuine pipeline filter is vital for system performance. Seadweer is a professional supplier offering this original Atlas Copco part. Choosing Seadweer ensures authenticity and reliability.

Contents

The Role of the PDX/PDXP 190 1624104104 Pipeline Filter

Clean compressed air is essential for many industrial applications. Particles, oil aerosols, and water droplets can damage sensitive pneumatic tools. They can also contaminate processes and finished products. The 1624104104 line filter is specifically designed to capture these contaminants. This protects equipment like dryers, regulators, and production machinery. Furthermore, it safeguards the quality of goods produced. Investing in proper filtration is critical.

Genuine 1624104104 Line Filter from Seadweer vs. Alternatives

Selecting the right pipeline filter directly impacts your air quality and system health. While several options exist, including aftermarket ones, they vary significantly in quality. Below is a comparison highlighting the differences between genuine and alternatives. Understanding these distinctions helps ensure you make the best choice.

| Feature | Genuine (from Seadweer) | High-Quality Aftermarket (Meeting OEM Specs) | Basic Aftermarket / Other |

| Filtration Standard | Meets/Exceeds ISO 8573-1 requirements | Aims to meet ISO 8573-1 requirements | Performance often unverified/lower |

| Efficiency | Guaranteed removal efficiency (micron/% ) | Claimed efficiency, may vary in practice | Efficiency often low or inconsistent |

| Media Quality | High-grade, durable filter media | Uses good quality media | Lower grade or less durable media |

| Pressure Drop | Minimized for energy efficiency | May have slightly higher pressure drop | Often causes significant pressure drop |

| Lifespan | Designed for maximum service hours | Lifespan may be shorter | Short lifespan, frequent replacement |

| Sealing/Fitment | Perfect fit and reliable sealing | Generally good fit, sealing can vary | Poor fit or sealing risk bypassing filter |

| Warranty/Reliability | Reliable performance, often warranted | Reliability can be good from known brands | Reliability often poor, little support |

Compatible Atlas Copco Systems and Filter Housings

The 1624104104 pipeline filter is designed to fit specific Atlas Copco filter housings. These housings are installed downstream of various compressor models. Proper compatibility between the pipeline filter and housing is essential for effective filtration. Using the wrong pipeline filter can lead to air bypass, reducing filtration efficiency. The table below lists common Atlas Copco filter housing series where this pipeline filter is typically used. Always verify the required epipeline filter number for your specific filter housing model.

| Compatible Filter Housing Series | Corresponding Compressor Series |

| G Series Filter Housings | Used with various GA, GX, ZR/ZT series |

| Q Series Filter Housings | Used with various GA, GX, ZR/ZT series |

| UD Series Filter Housings | Used with various GA, GX, ZR/ZT series |

| DD Series Filter Housings | Used with various GA, GX, ZR/ZT series |

| PD Series Filter Housings | Used with various GA, GX, ZR/ZT series |

| Other Filter Housings | Verify specific part number needed |

Note: This pipeline filter fits specific filter housing models within these series. Always consult your filter housing manual or compressor documentation to confirm compatibility with 1624104104.

Technical Specifications

Understanding the technical specifications of the 1624104104 pipeline filter is important. These specifications define its filtration capabilities and operating limits. As an Atlas Copco genuine part, it is engineered to meet precise standards. This ensures it performs reliably within the intended application. The table below provides key technical parameters for this filter. These parameters ensure it meets the required air quality standards when properly used.

| Parameter | Description/Value |

| Part Number | 1624104104 |

| Filtration Grade | Specific Atlas Copco Grade |

| Micron Rating | Defined particle size capture rating |

| Efficiency Rating | Specified percentage removal of contaminants |

| Max Operating Pressure | Rated for standard compressed air system pressure |

| Max Operating Temperature | Designed for typical pipeline temperatures |

| Filter Media Material | High-performance material |

| Element Type | Replacement Cartridge |

Installation and Maintenance Best Practices

Correct installation and timely replacement are key to filter effectiveness. Always ensure the compressed air system is depressurized before opening the filter housing. Refer to your filter housing manual for specific steps. Typically, this involves unscrewing the housing bowl, removing the old element and gaskets, cleaning the housing, installing the new element and gaskets correctly, and retightening the bowl to the specified torque. Regular maintenance involves monitoring the pressure differential across the filter. A rising pressure drop indicates the element is becoming clogged. Replacing the element according to the recommended service interval (often annually or based on pressure drop) ensures continuous clean air.

FAQs

Operators and maintenance staff frequently have questions about pipeline filters. Understanding their function, lifespan, and replacement procedure is crucial for effective maintenance. Addressing these common inquiries helps ensure optimal performance of your compressed air system. Here are answers to some points that often arise.

- Q1: What types of contaminants does the 1624104104 pipeline filter remove?

A1: The specific type of contaminant (e.g., solid particles, oil aerosols, water droplets) depends on the filter grade (PD, DD, UD, etc.) corresponding to the 1624104104 part number. It’s designed for general pipeline filtration. - Q2: How often should the 1624104104 pipeline filter be replaced?

A2: Replacement frequency is usually determined by monitoring the pressure differential across the filter housing. An increase indicates clogging. Atlas Copco also provides recommended service intervals, typically annually or after a certain number of operating hours, whichever comes first. - Q3: What are the signs that this pipeline filter needs replacing?

A3: The most reliable sign is an increased pressure drop reading on the differential pressure gauge or indicator across the filter housing. Other signs include reduced air flow downstream or visible contamination if the pipeline filter is bypassed or failed. - Q4: Is the 1624104104 pipeline filter from Seadweer a genuine Atlas Copco part?

A4: Yes, Seadweer is a trusted professional supplier specializing in original and genuine Atlas Copco air compressor spare parts, including the 1624104104 pipeline filter. - Q5: Can I clean and reuse the 1624104104 pipeline filter?

A5: No, pipeline filter like the 1624104104 are designed for single use. Attempting to clean them can damage the delicate filter media, reducing efficiency and potentially releasing captured contaminants downstream. They must be replaced.

More Line Filters List

If you need other Atlas Copco line filters, we provide more models in the table below or you can submit your requirements to us directly.

| 3002602110 | SCAVENGE LINE KIT | 3002-6021-10 |

| 3002606450 | FILTER LINE AUTO-DRAIN | 3002-6064-50 |

| 6996012685 | SKAVENGE LINE KIT | 6996-0126-85 |

| 6996012691 | SKAVENGE LINE KIT, 75 KW | 6996-0126-91 |

| 6996012885 | SKAVENGE LINE, KIT | 6996-0128-85 |

| 6996013248 | ELEMENT, LINE FILTER, EA150U | 6996-0132-48 |

| 6996013249 | ELEMENT, LINE FILTER, EA150H | 6996-0132-49 |

| 6996013250 | ELEMENT, LINE FILTER, EA220U | 6996-0132-50 |

| 6996013251 | ELEMENT, LINE FILTER, EA290U | 6996-0132-51 |

| 6996013252 | ELEMENT, LINE FILTER, EA290H | 6996-0132-52 |

| 6996013253 | ELEMENT, LINE FILTER, EA430U | 6996-0132-53 |

| 6996013254 | ELEMENT, LINE FILTER, G315 | 6996-0132-54 |

| 6996013255 | ELEMENT, LINE FILTER, C315 | 6996-0132-55 |

| 6996013256 | ELEMENT, LINE FILTER, EA220H | 6996-0132-56 |

| 6996013257 | ELEMENT, LINE FILTER, EA430H | 6996-0132-57 |

| 6996013278 | ELEMENT, LINE FILTER, TF 1900 | 6996-0132-78 |

| 8973000422 | KIT PIPE EXHAUST GAS(GASOLINE) | 8973-0004-22 |

| 8973037607 | VALVE LINE MF 1/8+ C0046 | 8973-0376-07 |

| 9098899800 | HOSE PILOT LINE FOR SOL. VALVE | 9098-8998-00 |

| 2202873100 | LABEL 3-PH SUPPLY LINE COMPRES | 2202-8731-00 |

| 2202873101 | LABEL 1-PH SUPPLY LINE DRYER | 2202-8731-01 |

| 2204118100 | SCAVENGE LINE ASSY C80 | 2204-1181-00 |

| 2204122751 | SINGLE LINE LABEL ELECT. RATES | 2204-1227-51 |

| 2204160550 | LIQUID LINE E15 50/60HZ | 2204-1605-50 |

| 2204160835 | INSULATION COMPR. SUCTION LINE | 2204-1608-35 |

| 2204165102 | LIQUID LINE E16-17 R410A | 2204-1651-02 |

| 2204213860 | PIPE ASSY SCAVENGE LINE S90 | 2204-2138-60 |

| 2014704129 | Check Valve Inline ( 0.25 P, 200 PSI ) | 2014704129 |

| 2014-7041-29 | Check Valve Inline ( 0.25 P, 200 PSI ) | 2014-7041-29 |

| 2902012600 | SCAVENGE LINE KIT | 2902-0126-00 |

| 2901164500 | SCAV LINE KIT | 2901-1645-00 |

| 2901161510 | SCAVENGE LINE KIT GA | 2901-1615-10 |

| 2901161500 | SCAVENGE LINE KIT | 2901-1615-00 |

| 2901107700 | SCAVENG LINE KIT | 2901-1077-00 |

| 2254704100 | LINER | 2254-7041-00 |

| 2250967300 | LINER | 2250-9673-00 |

| 2250635310 | LINE-FLEX | 2250-6353-10 |

| 2250635309 | LINE-FLEX | 2250-6353-09 |

| 2250587100 | LINER-CYL ASY | 2250-5871-00 |

| 2250420000 | LINER | 2250-4200-00 |

| 1622646200 | PIPE SCAVENGE LINE | 1622-6462-00 |

| 1622365480 | SCAVENGE LINE PIPE | 1622-3654-80 |

| 1622315700 | SCAVENGE LINE PIPE | 1622-3157-00 |

| 1622073800 | SCAVENGE LINE | 1622-0738-00 |

| 1622073700 | SCAVENGE LINE | 1622-0737-00 |

| 1622032000 | SCAVENGE LINE | 1622-0320-00 |

| 1622001710 | SCAVENGE LINE | 1622-0017-10 |

| 1622001700 | LINE-SCAVENGE | 1622-0017-00 |

| 1639696453 | CHECK VALVE DN150 CORELINE | 1639-6964-53 |

| 1649800104 | SCAVANGE LINE PIPE | 1649-8001-04 |

Conclusion

Maintaining clean compressed air is non-negotiable for protecting downstream equipment and ensuring product quality. The Atlas Copco 1624104104 pipeline filter plays a critical role in achieving this. Choosing a genuine pipeline filter guarantees the filtration performance your system needs. Seadweer is your reliable partner for sourcing this original part. By selecting Seadweer, you invest in the longevity and efficiency of your compressed air system. Ensure your air is clean and your operations run smoothly.

Anonymous –

Great value for money!

The 1624104104 filter for me is an excellent product! It delivers superior filtration efficiency, ensuring clean air supply and protecting equipment from contaminants. Great value for money!