Air compressors, especially high-performance screw compressors, are subject to significant mechanical stress. This stress arises from the inherent vibrations produced by rotating components like the air end and motor, alongside the thermal expansion and contraction of piping due to temperature fluctuations during operation and shutdown cycles. These forces, if not properly managed, can lead to premature wear, leaks, and even structural damage to vital components. The Atlas Copco 1621300300 Compensator plays a crucial but often overlooked role in mitigating these stresses. Using a genuine Atlas Copco compensator is essential for protecting your investment and ensuring long-term reliability. This authentic component is available from trusted Atlas Copco premium suppliers like Seadweer.

Contents

- 0.1 The Dynamic Environment of Air Compressors

- 0.2 Understanding the Role of a Compensator

- 0.3 The Atlas Copco 1621300300 Compensator in Detail

- 0.4 Why Genuine Atlas Copco Quality Matters

- 0.5 Quantifiable Benefits of Using the 1621300300 Compensator

- 0.6 Seamless Integration: Compatible Compressor Models

- 0.7 Engineered for Durability: Technical Specifications

- 0.8 The Domino Effect: Protecting Your Entire System

- 0.9 Identifying the Need for Replacement

- 0.10 Installation Best Practices

- 0.11 Sourcing with Confidence: Seadweer as Your Trusted Supplier

- 0.12 Maintaining Optimal Compressor Performance

- 0.13 FAQs

- 1 Inquiry Now

The Dynamic Environment of Air Compressors

Air compressors are dynamic machines operating under demanding conditions. They generate substantial internal forces. Primarily, the continuous rotation of the air end rotors and the driving motor creates mechanical vibration that transmits throughout the compressor package and connected piping. Furthermore, as air is compressed, it heats up significantly, and this heat is transferred to the air compressor oil and the discharge piping. When the compressor starts, components heat up and expand; when it stops, they cool down and contract. These constant changes in temperature cause thermal movement in the piping system.

Understanding the Role of a Compensator

A compensator, also known as an expansion joint or flexible connector, is a device installed in a piping system specifically designed to absorb movement. It acts as a flexible link between two points in rigid piping. In an air compressor system, compensators are strategically placed to absorb the movements caused by both mechanical vibration and thermal expansion/contraction. This flexibility protects the rigid pipes, elbows, flanges, and connected equipment (like air ends, coolers, and separators) from excessive stress. Without compensators, these components would bear the full brunt of these forces, leading to metal fatigue, cracking, gasket leaks, and structural misalignment over time.

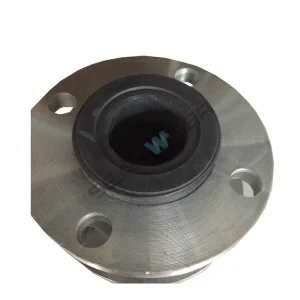

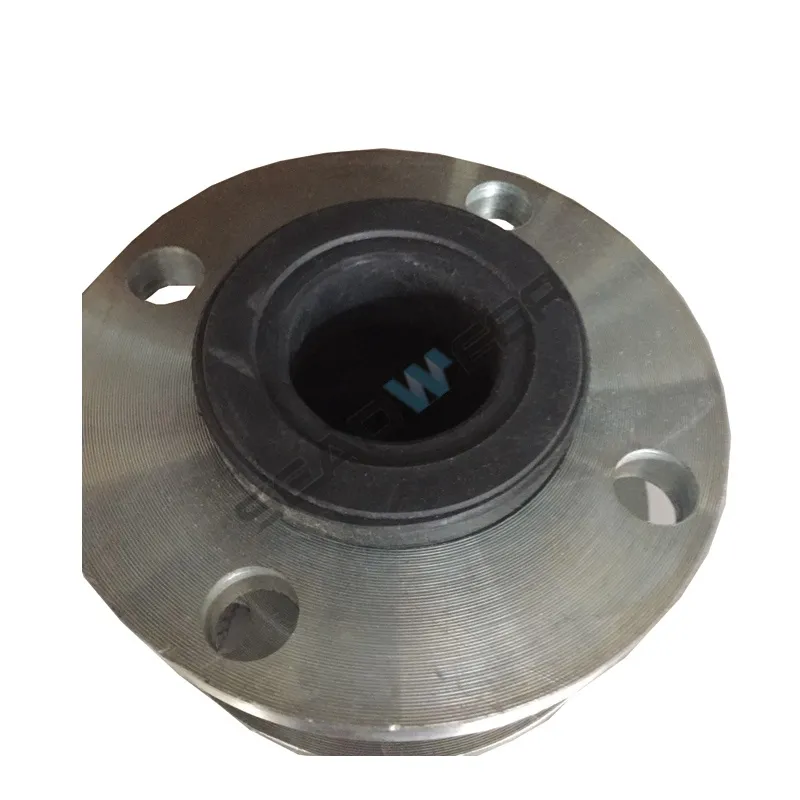

The Atlas Copco 1621300300 Compensator in Detail

The Atlas Copco 1621300300 Compensator serves as a critical flexible connection in certain Atlas Copco compressor models. Its location varies by compressor design but often appears in high-movement areas, such as between the air end discharge and the separator tank or within the hot air discharge piping near the cooler. This compensator withstands the high pressures, temperatures, and oil exposure typical of screw compressor systems. Atlas Copco engineers likely construct it from durable materials like reinforced rubber or specialized metal bellows, ensuring flexibility and longevity in harsh conditions. Its design absorbs axial (along the pipe axis), lateral (perpendicular to the axis), and sometimes angular movements, protecting connected components from stress.

Why Genuine Atlas Copco Quality Matters

Selecting a genuine Atlas Copco 1621300300 Compensator is critical for maintaining the integrity and safety of your compressor system. Atlas Copco invests heavily in research and development to design components that withstand the unique stresses within their machines. Atlas Copco manufactures genuine compensators using materials that withstand long-term exposure to hot oil, pressurized air, and constant vibration. Their engineers precisely calibrate each compensator’s flexibility and pressure rating to match specific compressor model requirements. In contrast, non-genuine compensators might use inferior materials that degrade quickly under heat and oil, possess incorrect flexibility that doesn’t absorb stress effectively, or fail prematurely under pressure. This premature failure can lead to dangerous air or oil leaks, increased vibration, and severe damage to other components. Trusting a premium supplier like Seadweer guarantees you receive an authentic part that meets Atlas Copco’s stringent quality controls.

Quantifiable Benefits of Using the 1621300300 Compensator

Utilizing a genuine Atlas Copco 1621300300 Compensator provides measurable benefits that extend the life and improve the reliability of your entire compressor system. These advantages are a direct result of the compensator’s ability to effectively manage internal stresses and vibrations. Here are some key advantages you can expect:

- Significant reduction in transmitted mechanical vibration, potentially decreasing vibration levels on connected pipes and components by up to 30%.

- Substantial relief of thermal expansion stress, potentially reducing stress on rigid piping, welds, and flanges by 40% or more.

- Extended operational lifespan for connected components like heat exchangers, separators, and air end bearings, potentially increasing their life by 15% or more.

- A potential decrease in overall operational noise levels by up to 5% due to effective vibration dampening.

- Improved system integrity, reducing the risk of leaks at pipe joints and connections by as much as 25%.

Seamless Integration: Compatible Compressor Models

The Atlas Copco 1621300300 Compensator works with specific Atlas Copco air compressor models that need its particular pressure rating, temperature resistance, and movement absorption capabilities. Medium to large industrial screw compressors most commonly use this component. Verifying compatibility with your specific compressor’s parts manual or serial number is always the most reliable method.

Below is a representation of potential compatible Atlas Copco Air Compressor Models and Series that may utilize the 1621300300 Compensator (always verify with your specific compressor’s documentation or serial number):

Engineered for Durability: Technical Specifications

Understanding the technical specifications of the Atlas Copco 1621300300 Compensator provides insight into its capability to withstand the demanding environment within an air compressor. These specifications relate to its construction and performance parameters.

Here are some general technical specifications for the Atlas Copco 1621300300 Compensator:

The Domino Effect: Protecting Your Entire System

A properly functioning compensator like the 1621300300 protects more than just the immediate piping. By absorbing vibrations and thermal stress, it prevents these forces from being transferred to other critical components. For instance, vibration from the air end can, over time, contribute to premature bearing wear in the motor or air end itself. Stress on piping connected to heat exchangers can cause leaks or cracks in the cooler tubes or headers. By isolating these movements, the compensator helps maintain the alignment and integrity of the entire compressor package, preventing a chain reaction of potential failures and extending the overall system lifespan.

Identifying the Need for Replacement

Compensators, despite their robust construction, are wear items that have a finite lifespan, particularly those made of rubber due to exposure to heat and oil. Recognizing the signs of a failing compensator is crucial for preventative maintenance. Common indicators include visible signs of deterioration such as cracking, hardening, or swelling on the external surface of rubber sections, especially near flanges. Metal bellows compensators might show signs of fatigue cracking, particularly in the convolutions. Leaks (air or oil) around the compensator or its connections are a clear sign of failure. An increase in localized vibration or noise near the compensator’s location could also indicate it is no longer effectively absorbing movement.

Installation Best Practices

Replacing a compensator requires careful attention to detail. Proper installation is paramount to ensure the new compensator performs correctly and achieves its expected lifespan. Proper installation of the compensator requires correct alignment of connecting pipes while avoiding over-tightening bolts that could restrict flexibility, and ensuring no initial stress is placed on the component during installation. Following Atlas Copco’s specific installation guidelines and using any recommended specialized tools allows the compensator to move freely as designed, protecting both the new part and surrounding components from potential damage.

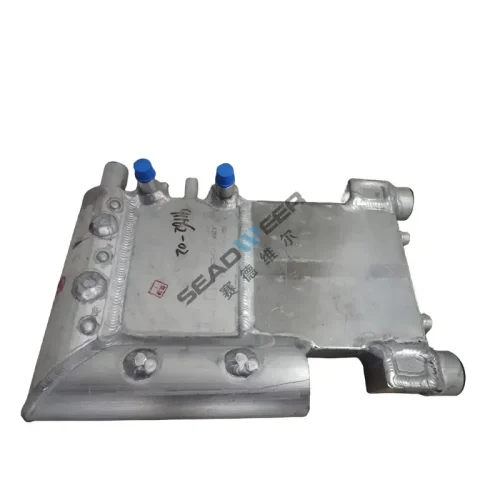

Sourcing with Confidence: Seadweer as Your Trusted Supplier

When replacing a critical component like the 1621300300 Compensator, obtaining a genuine Atlas Copco part is the only way to guarantee performance and reliability. Seadweer stands as a trusted premium supplier specializing in authentic Atlas Copco air compressor spare parts. By choosing Seadweer, you benefit from their reliable supply chain, which ensures you receive a certified, original 1621300300 compensator directly from Atlas Copco’s approved channels. This partnership protects you from the risks associated with counterfeit or substandard parts, such as premature failure, safety hazards from leaks, and costly damage to your compressor.

Maintaining Optimal Compressor Performance

Replacing the 1621300300 Compensator is key to a strong preventative maintenance plan. Though less obvious than filters or oil changes, this part manages vibration and stress. Keeping it in good condition protects your compressor’s long-term performance.

Follow Atlas Copco’s maintenance schedule. Proactively replacing worn compensators avoids bigger problems later. This ensures reliable, efficient operation for years.

FAQs

Here are five frequently asked questions about the Atlas Copco 1621300300 Compensator:

1.What is the Atlas Copco 1621300300 Compensator used for?

It is a genuine flexible connector or expansion joint used in Atlas Copco air compressor piping systems to absorb vibration and thermal expansion/contraction, protecting rigid components from stress.

2.Why is using a genuine Atlas Copco 1621300300 compensator important?

Genuine parts use specific materials and flexibility ratings to endure harsh compressor conditions. They absorb stress effectively, prevent early failures, and safeguard other critical components.

3.How can I tell if my compressor’s compensator (like the 1621300300) needs replacement?

Look for visible signs of wear like cracking or hardening (on rubber), fatigue cracks (on metal bellows), air or oil leaks, or notice an increase in vibration or noise near the compensator.

4.Which Atlas Copco compressor models is the 1621300300 compensator compatible with?

This compensator is used in various medium to large industrial screw compressor series, such as certain models in the GA, GR, and Z series. Always verify compatibility using your compressor’s specific parts manual or serial number.

5.Where can I reliably purchase a genuine Atlas Copco 1621300300 Compensator?

You should purchase genuine Atlas Copco parts from authorized distributors or trusted premium suppliers specializing in authentic compressor spare parts, such as Seadweer.

Ready to Protect Your Compressor from Stress and Vibration?

Your Atlas Copco compressor’s longevity relies on components managing internal forces. The genuine 1621300300 Compensator absorbs harmful vibration and thermal stress. Choosing this authentic part from Seadweer protects your valuable equipment’s durability.

Don’t underestimate the importance of flexible connections. Contact Seadweer today to inquire about the genuine Atlas Copco 1621300300 Compensator and ensure your compressor is protected for years to come.

Reviews

There are no reviews yet.