At the core of every high-performing oil-free air compressor lies the airend, the precision-engineered component responsible for the actual compression process. For industries demanding the purest air, free from any oil contamination, Atlas Copco’s ZR and ZT series compressors stand as industry leaders. Central to their exceptional performance is the genuine Atlas Copco Airend, specifically identified by part number 1616711781. This crucial component ensures the delivery of ISO 8573-1 Class 0 certified compressed air, offering uncompromising purity for critical applications.

When the time comes for a major overhaul, rebuild, or replacement, installing a genuine airend is not merely an option; it is an absolute necessity for protecting your investment, maintaining certified air quality, and ensuring the continued efficiency of your oil-free compressed air system. For businesses requiring this authentic, high-precision core component, Seadweer stands as a professional and trusted supplier specializing in genuine Atlas Copco compressor parts. Consequently, choosing Seadweer ensures you acquire an airend manufactured to the exact specifications and uncompromising quality standards set by Atlas Copco.

Contents

- 1 Understanding the Oil-Free Airend’s Significance

- 2 Introducing the Genuine Atlas Copco 1616711781 AirEnd

- 3 Key Advantages of the Genuine 1616711781 AirEnd

- 4 Genuine 1616711781 AirEnd vs. Non-Genuine Alternatives

- 5 Atlas Copco ZR/ZT Compressors Using 1616711781 AirEnd

- 6 Representative Technical Specifications for 1616711781 AirEnd

- 7 Installation Steps for Atlas Copco 1616711781 AirEnd

- 8 Frequently Asked Questions (FAQs)

- 9 Conclusion

- 10 Inquiry Now

Understanding the Oil-Free Airend’s Significance

The airend represents the intricate engineering marvel at the very heart of an oil-free rotary screw compressor. Unlike oil-injected designs, oil-free airends achieve compression without injecting oil into the compression chamber. Instead, precisely machined male and female rotors intermesh, drawing in air and compressing it as the volume between the lobes decreases. Separate, oil-lubricated gears synchronize the rotors, preventing metal-to-metal contact within the compression chamber. This fundamental design ensures that the compressed air never comes into contact with oil, guaranteeing absolute oil-free output. The airend’s flawless operation directly impacts several critical aspects of your compressor system. Firstly, it ensures the consistent delivery of certified Class 0 air, essential for sensitive processes. Secondly, its precision contributes significantly to the compressor’s overall energy efficiency. Finally, the quality and durability of the airend determine the long-term reliability and lifespan of the entire compressor unit.

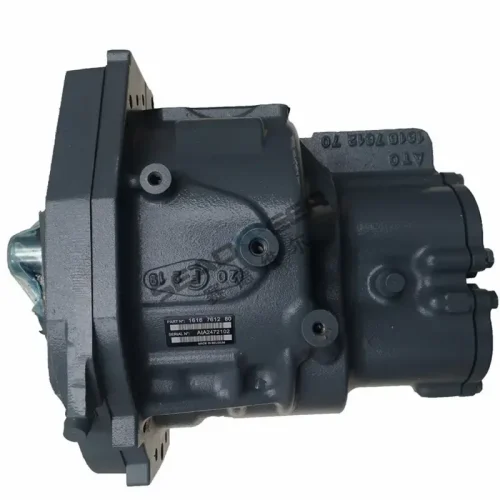

Introducing the Genuine Atlas Copco 1616711781 AirEnd

The Genuine Atlas Copco Airend, identified by part number 1616711781, is a meticulously crafted assembly specifically designed for seamless integration into designated Atlas Copco ZR and ZT series oil-free rotary screw compressors. This part number signifies a core compression unit engineered for precise air compression without any oil contamination. Atlas Copco manufactures this airend with unparalleled attention to detail, utilizing high-quality materials and advanced machining processes. It features precision-ground rotors, durable bearings designed for long life, and advanced sealing technologies that prevent external contaminants from entering the compression chamber. The robust casing provides structural integrity and minimizes noise and vibration during operation. Each 1616711781 airend undergoes rigorous testing, which guarantees its performance, efficiency, and structural integrity under demanding operating conditions. As an authentic component, this airend restores the compressor’s original performance characteristics, ensuring optimal air purity, energy efficiency, and a long operational lifespan.

Key Advantages of the Genuine 1616711781 AirEnd

Opting for the Genuine Atlas Copco 1616711781 Airend delivers a range of significant advantages that directly impact your oil-free compressor’s performance, air quality, and operational costs.

- Guaranteed Class 0 Air Purity: This airend is specifically engineered to deliver absolutely oil-free air, certified to ISO 8573-1 Class 0, the highest standard for air purity. This protects critical processes and products from contamination.

- Superior Energy Efficiency: Precision-machined rotors and optimized internal clearances minimize energy losses during compression. This translates to lower power consumption and significant operational cost savings over the airend’s lifespan.

- Extended Service Life: High-quality materials, robust bearings, and advanced manufacturing techniques ensure exceptional durability. This significantly extends the airend’s operational life, reducing the frequency of costly replacements or major overhauls.

- Precision Engineering & Manufacturing: Atlas Copco applies stringent quality control and advanced machining processes. This guarantees precise tolerances, optimal performance, and consistent reliability.

- Minimized Vibration & Noise: The balanced design and robust construction of the genuine airend contribute to smoother operation, which reduces vibration levels and minimizes noise output. This improves the working environment.

- Exact Compatibility & Seamless Integration: Designed and tested by Atlas Copco, this airend perfectly integrates into specific ZR/ZT compressor models. This ensures proper fit, optimal performance, and maintains the compressor’s warranty.

The Seadweer Advantage: Your Authentic Source for Genuine 1616711781 AirEnd

When your oil-free compressor’s core compression element, the airend, requires attention, selecting a trustworthy supplier remains paramount. Seadweer stands as a professional provider entirely dedicated to supplying genuine Atlas Copco air compressor parts. Their unwavering commitment to authenticity means every 1616711781 Airend you acquire from them is a product manufactured to Atlas Copco’s exact engineering specifications and undergoes rigorous factory quality control. Purchasing from Seadweer helps eliminate the inherent risks associated with non-genuine airends. These risks include compromised air purity, lower energy efficiency, premature wear of rotors or bearings, increased vibration, or even catastrophic failure, all of which can lead to extensive downtime and costly repairs. Therefore, partnering with Seadweer provides unwavering confidence in the quality, reliability, and long-term protective capabilities of this crucial compressor component.

Genuine 1616711781 AirEnd vs. Non-Genuine Alternatives

Choosing the Genuine Atlas Copco 1616711781 Airend over non-genuine alternatives is a critical decision that profoundly impacts your oil-free compressor’s performance, air purity, and overall operational costs. Non-genuine airends or refurbished units from unauthorized sources may offer a lower initial price, but their hidden costs often outweigh any perceived savings through reduced efficiency, compromised air quality, and potential damage to other expensive components.

| Feature | Genuine Atlas Copco 1616711781 AirEnd | Non-Genuine Alternatives |

| Air Purity Certification | Guaranteed ISO 8573-1 Class 0 | Often cannot meet, or claims without certification |

| Energy Efficiency | Optimized design for lowest kW/m鲁/min | Less efficient, resulting in higher energy consumption |

| Rotor/Bearing Quality | High-precision, durable materials, superior surface finish | Inferior materials, imprecise machining, accelerated wear |

| Sealing Technology | Advanced, long-life seals for oil-free integrity | Substandard seals, leading to oil contamination risks |

| Manufacturing Precision | Exact tolerances, strict quality control | Inconsistent tolerances, poor alignment, premature failure |

| Vibration & Noise | Minimized vibration, low noise emission | Higher vibration, increased noise, component stress |

| Lifespan | Engineered for long operational life | Significantly shorter lifespan, high risk of early failure |

| Warranty Support | Full manufacturer warranty | No warranty, or limited third-party warranty |

| System Integration | Perfect fit, seamless integration with control system | May require modifications, impacting system performance |

This comparison clearly demonstrates that genuine airends are the result of extensive research, development, and stringent quality control processes. Non-genuine parts, conversely, often fall short in critical areas, risking contaminated air, reduced efficiency, accelerated wear, and ultimately, a much higher total cost of ownership due to catastrophic failures and extended downtime.

Atlas Copco ZR/ZT Compressors Using 1616711781 AirEnd

The Atlas Copco 1616711781 Airend is a specific core component designed for particular Atlas Copco ZR and ZT series oil-free rotary screw compressors. Its precise engineering and integration ensure optimal performance within these specialized machines. This airend is typically found in various ZR/ZT models where its capacity, pressure range, and physical dimensions are appropriate. The table below lists representative Atlas Copco ZR/ZT compressor series and examples of models within those series that may utilize the 1616711781 airend. However, to guarantee compatibility for your exact compressor unit, it is absolutely essential to consult your machine’s technical documentation, specific part lists, or serial number, as airend requirements can vary even within the same series depending on the specific model variant, power rating, or manufacturing date.

| Compressor Series | Typical Application Models (Representative) |

| ZR Series (Oil-Free Rotary) | ZR 110-160 (Specific variants, check manual) |

| ZT Series (Oil-Free Rotary) | ZT 110-160 (Specific variants, check manual) |

| Older ZR/ZT Variants | Some legacy ZR/ZT models (verify) |

| VSD (Oil-Free) | Certain ZR/ZT VSD variants (verify) |

Note: This table provides representative examples; specific compatibility with the 1616711781 Airend part number must be verified based on your compressor’s full model, variant, and serial number, as specified in your documentation or by contacting a specialist.

Representative Technical Specifications for 1616711781 AirEnd

The Genuine Atlas Copco 1616711781 Airend adheres to a specific set of highly precise technical parameters that define its performance capabilities and physical characteristics. These specifications ensure it functions flawlessly within the compressor system and delivers the expected oil-free air. While the precise, detailed engineering specifications are proprietary to Atlas Copco, the table below outlines representative technical characteristics typical of a high-quality oil-free airend designed for industrial screw compressors. These properties directly contribute to its efficiency, purity, and longevity.

| Parameter | Representative Characteristic / Value (Typical) |

| Compression Principle | Oil-Free Twin Screw Rotary |

| Air Purity Class | ISO 8573-1 Class 0 |

| Max Operating Pressure | Up to 10.5 bar (152 psi) to 13 bar (188 psi) |

| Rated Flow Capacity | Varies by compressor model (e.g., 10-25 m³/min) |

| Shaft Speed | High RPM (specific range for optimal performance) |

| Power Range | Matched to compressor motor (e.g., 75 kW to 160 kW) |

| Noise Level Contribution | Engineered for low vibration and acoustic output |

| Lubrication (Gears) | Separate oil circuit, sealed from air path |

| Housing Material | High-grade Cast Iron or Aluminum Alloy |

Note: These parameters are representative. The precise technical specifications for Atlas Copco Airend part number 1616711781 are defined by Atlas Copco’s engineering for its specific application and may vary slightly based on production batches.

Installation Steps for Atlas Copco 1616711781 AirEnd

Replacing or installing an Atlas Copco 1616711781 Airend is a highly complex and critical procedure. It requires specialized tools, precise alignment, and extensive technical expertise. Incorrect installation can lead to severe damage to the airend itself, the motor, or other compressor components, resulting in catastrophic failure and costly downtime. It is absolutely imperative that this procedure be performed only by highly qualified, certified Atlas Copco compressor technicians or authorized service personnel.

General Installation Steps (Requires Specialized Expertise & Tools):

Critical Safety Protocols:

Crucially, ensure the compressor is fully shut down, de-energized, and isolated from all power sources. Properly lock out/tagged out the electrical supply. Relieve all internal air pressure from the system. Allow the compressor to cool completely. Drain all oil from the gear housing.

Disassembly & Access:

Carefully disconnect all air piping (inlet and outlet), lubrication lines, and any sensors or wiring attached to the old airend. Unbolt any mounting brackets or couplings connecting the airend to the motor and frame. Use appropriate lifting equipment, as airends can be heavy.

Remove Old Airend:

Once disconnected, carefully lift and remove the old airend from the compressor frame. Exercise extreme caution to avoid damaging any surrounding components or the motor shaft.

Inspect & Prepare Mounting Area:

Thoroughly clean the mounting surfaces on the compressor frame and the motor shaft. Inspect for any damage, corrosion, or debris. Ensure all alignment pins or dowels are clean and in good condition.

Prepare New Airend:

Unpack the new, Genuine Atlas Copco 1616711781 Airend. Inspect it for any transit damage. Ensure all new gaskets, O-rings, and coupling elements (if part of the replacement kit) are present. Apply a thin film of clean, recommended lubricant to any coupling surfaces as specified.

Install New Airend:

Carefully lower the new airend onto the compressor frame, ensuring perfect alignment with the motor shaft and mounting points. Secure all mounting bolts to the specified torque values, following any recommended tightening sequence. Precision alignment of the coupling is critical.

Reconnect Systems:

Reconnect all air piping, lubrication lines, sensors, and wiring to the new airend. Use new seals, gaskets, or O-rings as specified by the manual. Tighten connections securely.

Refill Oil (Gearbox):

Refill the airend’s gear housing with the correct type and quantity of genuine Atlas Copco gear lubricant. This is separate from the main compressor oil circuit if it’s an oil-injected compressor.

Initial Run & Testing:

Restore power to the compressor. Perform a controlled initial startup sequence, following manufacturer guidelines. Carefully monitor for any unusual noises, vibrations, or leaks. Check operating parameters (pressure, temperature, power consumption) to ensure they are within specification. A thorough test run is essential before full production.

Disclaimer: This guide is a simplified overview. Replacement of an Atlas Copco compressor airend is a highly specialized and complex procedure requiring significant technical expertise, specialized tooling, and adherence to strict safety protocols. It must only be performed by certified and authorized Atlas Copco service technicians following all manufacturer guidelines. Attempting this without proper training can result in severe injury, catastrophic equipment damage, and voided warranties.

Frequently Asked Questions (FAQs)

Q1: What is the primary function of Atlas Copco 1616711781 Airend? A1: This airend is the core compression element for Atlas Copco ZR and ZT series oil-free rotary screw compressors, responsible for compressing air without introducing oil into the compression chamber, thus delivering ISO 8573-1 Class 0 air.

Q2: Why is it critical to use a genuine 1616711781 Airend for my ZR/ZT compressor? A2: A genuine airend guarantees certified oil-free air, optimal energy efficiency, long service life, and perfect integration with your compressor’s system. Non-genuine alternatives risk contamination, inefficiency, and premature failure.

Q3: What are the main signs that an airend may need replacement or service? A3: Signs include increased noise or vibration, reduced compressed air output, higher power consumption for the same output, elevated discharge temperatures, or unusual oil consumption in the gear housing (if applicable).

Q4: Can I rebuild an old airend instead of replacing it with a new one? A4: Rebuilding an airend is possible, but it requires highly specialized equipment and expertise. For oil-free airends like the 1616711781, maintaining Class 0 purity and original efficiency after a rebuild is challenging without factory-level precision. A new genuine airend often provides the best long-term value and peace of mind.

Q5: How does the oil-free design of the ZR/ZT airend benefit my operations? A5: The oil-free design eliminates oil contamination risks, protecting sensitive downstream equipment and products, reducing maintenance costs associated with oil removal, and ensuring compliance with stringent air quality standards for critical applications.

Conclusion

The Genuine Atlas Copco 1616711781 Airend is the undisputed heart of your ZR/ZT oil-free air compressor, embodying precision, efficiency, and unwavering reliability. Its advanced engineering ensures the consistent delivery of the purest, oil-free compressed air, a non-negotiable requirement for many industries. By choosing this authentic core component from a professional Atlas Copco air compressor supplier like Seadweer, you guarantee the uncompromising quality and exact performance your Atlas Copco compressor demands. This action safeguards your investment, maintains your operational integrity, and secures the highest possible return from your air compression system. Trusting genuine components for the very core of your machine ultimately translates to superior operational value and complete peace of mind.

Anonymous_Buyer –

The difference was night and day!

After replacing our failing air end with the genuine Atlas Copco 1616711781 unit on our ZR75, the difference was night and day! The precision-balanced rotors eliminated all harmonic resonance issues we’d battled for years. Oil retention is perfect – zero carryover in our weekly tests. Although the price of this genuine air end is relatively high, the 18-month return on investment through energy savings and zero downtime makes it our wisest investment.

Seadweer –

Thank you for choosing seadweer to supply you with the original Atlas Copco 1616711781 air end. The quality of the original product is beyond doubt. We look forward to our next cooperation.