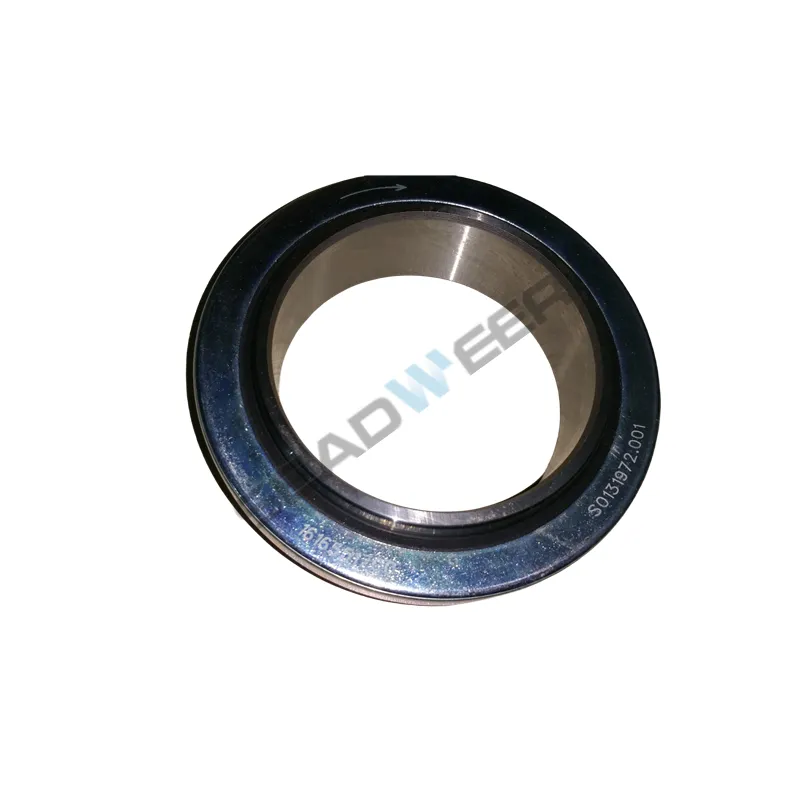

In the complex machinery of an industrial air compressor, even the smallest components play critically important roles. Among these, the oil seal, though diminutive in size, performs an absolutely vital function: it seals rotating or oscillating parts, effectively preventing lubricant leakage while simultaneously excluding external contaminants like dust and moisture. For Atlas Copco air compressors, the Genuine Atlas Copco Oil Seal 1616551700, stands as a testament to precision engineering in these essential sealing applications. This specialized seal ensures the integrity of the compressor’s lubrication system, protecting critical bearings and preventing costly oil loss.

When your compressor’s existing oil seal shows signs of wear, leakage, or age, installing a genuine unit is not merely a recommendation; it is an absolute necessity for protecting your investment and ensuring the continued reliability and longevity of your equipment. For businesses requiring this authentic, high-performance sealing component, Seadweer stands as a professional and trusted supplier specializing in genuine Atlas Copco compressor parts. Consequently, choosing Seadweer ensures you acquire a seal manufactured to the exact specifications and uncompromising quality standards set by Atlas Copco.

Contents

- 1 Why Oil Seals are Critical for Compressor Health

- 2 Introducing the Genuine Atlas Copco Oil Seal 1616551700

- 3 Key Advantages of the Genuine 1616551700 Oil Seal

- 4 Your Authentic Source for Genuine 1616551700 Oil Seal

- 5 Genuine Oil Seal vs. Non-Genuine Oil Seal

- 6 Technical Specifications for 1616551700 Oil Seal

- 7 Installation Steps for 1616551700 Oil Seal

- 8 Frequently Asked Questions (FAQs)

- 9 Conclusion

- 10 Inquiry Now

Why Oil Seals are Critical for Compressor Health

The oil seal acts as a silent guardian within the compressor, performing a dual protective function. Firstly, it diligently retains lubricating oil within specific compartments, such as the gearbox or airend, preventing its escape along rotating shafts. Lubricant forms the lifeblood of the compressor, protecting moving parts from friction and wear. Secondly, the oil seal effectively excludes external contaminants, including dust, dirt, and moisture, from entering sensitive areas where they could cause abrasive wear or corrosion. Failure of an oil seal leads to several detrimental consequences. Oil leaks increase lubricant consumption, which means higher operational costs. Moreover, escaping oil can contaminate the compressed air, jeopardizing downstream equipment and finished products. Furthermore, ingress of contaminants can quickly damage bearings and other precision components, leading to expensive repairs and unscheduled downtime. Therefore, a high-quality, properly functioning oil seal remains indispensable for protecting the compressor’s vital internal mechanisms and ensuring its reliable, long-term operation.

Introducing the Genuine Atlas Copco Oil Seal 1616551700

The Genuine Atlas Copco Oil Seal, identified by part number 1616551700, is a precision-engineered sealing solution specifically designed for demanding applications within Atlas Copco air compressors. This part number signifies a seal meticulously crafted to withstand the challenging operating conditions typically found in industrial compressors, including high shaft speeds, elevated temperatures, and varying pressures. Atlas Copco manufactures this oil seal with exceptional attention to detail, utilizing advanced material compositions. These often include specialized elastomers such as Viton (FKM) for high-temperature resistance, or NBR (Nitrile Butadiene Rubber) for general purpose and excellent oil resistance, sometimes combined with a durable metal case and an internal garter spring for consistent lip contact. This robust lip design effectively creates a barrier, preventing lubricant escape and contaminant ingress. Each 1616551700 oil seal undergoes rigorous testing, which guarantees its sealing integrity, durability, and resistance to environmental factors. As an authentic component, this oil seal restores the compressor’s original leak-prevention capabilities, securing lubricant integrity and protecting sensitive internal parts.

Key Advantages of the Genuine 1616551700 Oil Seal

Opting for the Genuine Atlas Copco Oil Seal 1616551700 delivers a range of significant advantages that directly impact your compressor’s long-term reliability and operational costs.

- Superior Leak Prevention: The precision manufacturing and high-quality lip design ensure an exceptionally tight seal around rotating shafts. This effectively prevents costly lubricant leakage, maintaining optimal oil levels within critical components.

- Enhanced Contamination Exclusion: The robust sealing lip actively blocks the entry of dust, dirt, and moisture from the external environment. This protects internal bearings and precision parts from abrasive wear and corrosion, extending their lifespan.

- Extended Service Life: Made from specialized, durable elastomers and designed to withstand harsh operating conditions, this genuine seal offers a significantly longer operational life. This reduces the frequency of replacements and associated maintenance efforts.

- Robust Material Composition: Atlas Copco selects specific materials (e.g., FKM, NBR) known for their excellent resistance to compressor lubricants, high temperatures, and chemical degradation. This ensures consistent performance over time.

- Precision Fit and Performance: Engineered to exact dimensions and tolerances, the seal perfectly fits its intended application. This guarantees optimal compression of the sealing lip, preventing bypass and ensuring consistent sealing efficiency.

- High Temperature & Pressure Resistance: The genuine seal is specifically designed to perform reliably under the elevated temperatures and pressure differentials found within compressor environments. This prevents premature hardening, cracking, or failure.

Your Authentic Source for Genuine 1616551700 Oil Seal

When your compressor’s vital oil seal requires replacement, selecting a trustworthy Atlas Copco spare parts supplier remains paramount. Seadweer stands as a professional provider entirely dedicated to supplying genuine Atlas Copco air compressor parts and consumables. Their unwavering commitment to authenticity means every 1616551700 Oil Seal you acquire from them is a product manufactured to Atlas Copco’s exact engineering specifications and undergoes rigorous factory quality control. Purchasing from Seadweer helps eliminate the inherent risks associated with non-genuine seals. These risks include inferior material quality, inaccurate dimensions, poor lip design, or inadequate temperature/pressure resistance, all of which can lead to rapid lubricant leakage, increased contamination ingress, and ultimately, costly damage to bearings and other precision components. Therefore, partnering with Seadweer provides unwavering confidence in the quality, reliability, and long-term protective capabilities of this crucial sealing component.

Genuine Oil Seal vs. Non-Genuine Oil Seal

Choosing the Genuine Atlas Copco Oil Seal 1616551700 over non-genuine alternatives is a critical decision that profoundly impacts your compressor’s performance, reliability, and overall operational costs. Non-genuine seals may offer a lower initial price, but their hidden costs often outweigh any perceived savings through increased oil consumption, premature component wear, and potential system damage.

| Feature | Genuine Atlas Copco 1616551700 Oil Seal | Non-Genuine Alternatives |

| Material Quality | High-grade, application-specific elastomers (e.g., FKM, NBR) | Inferior, generic rubber, poor resistance to oil/temp |

| Lip Design & Integrity | Precision-molded, optimized profile for effective sealing | Inconsistent molding, easily damaged, poor sealing contact |

| Garter Spring Quality | High-tensile, corrosion-resistant spring for consistent pressure | Weak, easily corroded, or missing spring, losing sealing force |

| Dimensional Accuracy | Exact fit to shaft and housing bores | Inconsistent dimensions, leading to leaks or difficult installation |

| Temperature Resistance | Designed for compressor operating temperatures | Lower temperature limits, leading to hardening/cracking |

| Pressure Resistance | Withstands typical pressure differentials | Poor pressure resistance, causing premature failure |

| Lifespan | Engineered for long operational life | Significantly shorter lifespan, requiring frequent changes |

| Contamination Exclusion | Superior barrier against dust and moisture | Weak barrier, allowing contaminants to enter |

| Warranty Impact | Maintains equipment warranty (check terms) | Can void equipment warranty, no manufacturer support |

This comparison clearly demonstrates that genuine oil seals are the result of extensive research, development, and stringent quality control processes. Non-genuine parts, conversely, often fall short in critical areas, risking significant lubricant loss, bearing damage, and ultimately, a higher total cost of ownership due to accelerated component degradation and unexpected downtime.

Technical Specifications for 1616551700 Oil Seal

The Genuine Atlas Copco Oil Seal 1616551700 adheres to a specific set of highly precise technical parameters that define its performance capabilities, dimensions, and material composition. These specifications ensure it functions flawlessly within the compressor system and provides robust sealing. While the precise, detailed engineering specifications are proprietary to Atlas Copco, the table below outlines representative technical characteristics typical of a high-quality industrial oil seal designed for compressor applications. These properties contribute directly to its sealing efficiency, durability, and operational limits.

| Parameter | Representative Characteristic / Value (Typical) |

| Material | FKM (Fluoroelastomer / Viton) or NBR (Nitrile Butadiene Rubber) |

| Configuration | Single or Double Lip with Garter Spring |

| Operating Temperature Range | -20°C to +180°C (-4°F to +356°F) (for FKM); -30°C to +100°C (for NBR) |

| Max Pressure Differential | Up to 0.5 bar (7.25 psi) (depending on type) |

| Max Shaft Speed | Up to 30 m/s (5900 ft/min) (depending on shaft diameter) |

| Dimensions | Inner Diameter (ID), Outer Diameter (OD), Width (mm) |

| Shaft Surface Speed | Critical for seal performance |

| Resistance | Excellent resistance to compressor lubricants, heat, and aging |

Note: These parameters are representative. The precise technical specifications for Atlas Copco Oil Seal part number 1616551700 are defined by Atlas Copco’s engineering for its specific application.

Installation Steps for 1616551700 Oil Seal

Installing an Atlas Copco Oil Seal 1616551700 is a precise and delicate task. Proper installation is absolutely crucial to ensure effective sealing and prevent premature failure. Incorrect handling or installation can easily damage the seal lip, leading to immediate leaks. It is imperative that this procedure be performed by qualified, experienced technicians using appropriate tools and following manufacturer guidelines.

General Installation Steps (Requires Precision & Care):

Critical Safety Protocols

Crucially, ensure the compressor is completely shut down, de-energized, and isolated from all power sources. Properly lock out/tagged out the electrical supply. Relieve all internal air pressure. Allow the compressor to cool completely. Ensure all relevant oil systems are drained to prevent spillage.

Access and Disassembly

Identify the component where the oil seal is located (e.g., airend, gearbox, motor housing). Carefully disassemble the surrounding components to gain full access to the old oil seal. Note the orientation of the old seal before removal.

Remove Old Seal

Using a specialized seal removal tool or a non-marring pry tool, carefully extract the old oil seal. Exercise extreme caution to avoid scratching or damaging the shaft or the housing bore.

Inspect Shaft and Bore

Thoroughly clean the shaft surface where the seal will run. Inspect for any nicks, burrs, rust, or wear grooves. Smooth any imperfections with very fine abrasive paper if necessary, then clean again. Clean the seal housing bore, removing any old sealant or debris.

Prepare New Seal

Unpack the new, Genuine Atlas Copco Oil Seal 1616551700. Inspect it for any visible defects. Apply a thin, uniform film of clean compressor lubricant to the inner sealing lip and the outer diameter of the seal.

Install New Seal

Using a dedicated seal installation tool (a cylindrical drift slightly smaller than the outer diameter of the seal, or a sleeve that fits over the shaft), gently and evenly press the new seal into its bore. Ensure the seal enters squarely and does not cock or deform. The lip must face the correct direction (typically towards the lubricant). Avoid touching the sealing lip with your fingers.

Protect During Shaft Insertion (if applicable)

If the shaft is inserted after the seal, use a shaft protector sleeve or electrical tape to cover any sharp splines, keyways, or threads that could damage the seal lip during assembly. Remove the protector once the seal is over the critical area.

Reassemble Components

Reinstall all disassembled components, ensuring all bolts are tightened to specified torque values. Reconnect any lines or sensors.

Refill Oil and Test

Refill the system with the correct type and quantity of compressor oil. Perform a careful initial startup, monitoring for any leaks around the newly installed seal. Observe for any abnormal noises or temperatures.

Disclaimer: This guide provides general steps. Replacement of an Atlas Copco oil seal is a precision task requiring specific tools, factory-level technical knowledge, and adherence to strict safety protocols. It must only be performed by certified and authorized Atlas Copco service technicians. Attempting this without proper training can result in immediate seal failure, lubricant loss, severe equipment damage, and voided warranties.

Frequently Asked Questions (FAQs)

Q1: What is the main purpose of the Atlas Copco Oil Seal 1616551700? A1: This oil seal’s main purpose is to prevent the leakage of lubricating oil from rotating shafts and to protect internal components from external contaminants like dust and moisture.

Q2: Why is it crucial to use a genuine 1616551700 Oil Seal? A2: A genuine seal guarantees the correct material composition, precision dimensions, and robust design needed to withstand compressor operating conditions, ensuring effective long-term sealing, preventing leaks, and protecting critical parts.

Q3: How often should oil seals be inspected or replaced in a compressor? A3: Oil seals should be inspected during regular compressor maintenance routines. They typically require replacement during major overhauls or whenever signs of leakage or degradation appear, such as hardening, cracking, or visible wear on the shaft.

Q4: What are the risks if an oil seal fails in my compressor? A4: A failed oil seal can lead to significant lubricant leakage, increased oil consumption, contamination of the compressed air, and potentially severe damage to bearings, gears, or other precision components due to insufficient lubrication or abrasive wear.

Q5: What materials are typically used in the genuine 1616551700 oil seal? A5: Genuine Atlas Copco oil seals utilize high-performance elastomers like FKM (Viton) or NBR (Nitrile Butadiene Rubber), chosen for their specific resistance to compressor oils, high temperatures, and chemical degradation, ensuring optimal performance.

Conclusion

The Genuine Atlas Copco Oil Seal 1616551700, though a small part, performs an undeniably critical function in maintaining the integrity and reliability of your Atlas Copco air compressor. Its precision engineering and advanced materials provide robust protection against lubricant loss and contamination ingress, directly contributing to extended component life and reduced operational costs. By choosing this authentic sealing solution from a professional supplier like Seadweer, you guarantee the uncompromising quality and exact fit your compressor needs. This action safeguards your investment and secures the uninterrupted performance of your air compression system. Trusting genuine parts for every part of your machine ultimately translates to superior operational value and complete peace of mind.

Anonymous –

A genuine part that delivers reliable performance.

The Atlas Copco Oil Seal 1616551700 works perfectly in my air compressor! No leaks, smooth operation, and long-lasting durability. A genuine part that delivers reliable performance.