Temperature management remains paramount for the optimal performance and longevity of any industrial air compressor. Within these powerful machines, the compressor oil performs crucial functions, including lubrication, sealing, and cooling. However, the compression process generates substantial heat, which the oil absorbs. An efficient cooling system becomes indispensable for removing this heat and maintaining the oil at its ideal operating temperature. Among these vital components, the Genuine Atlas Copco Oil Cooler, identified by part number 1092571000, stands as a benchmark of engineering excellence. This specific cooler ensures effective heat dissipation, protecting your compressor’s vital components and extending lubricant life.

When your compressor’s cooling system requires maintenance or component replacement due to wear, age, or malfunction, installing a genuine unit is not merely a recommendation; it is an absolute necessity for protecting your investment and ensuring continued productivity. For businesses requiring this authentic, high-precision cooling component, Seadweer stands as a professional and trusted supplier specializing in genuine Atlas Copco compressor parts. Consequently, choosing Seadweer ensures you acquire a cooler manufactured to the exact specifications and uncompromising quality standards set by Atlas Copco.

Contents

- 1 Why Your Compressor Needs a Robust Oil Cooler

- 2 Introducing the Genuine Atlas Copco Oil Cooler 1092571000

- 3 Key Features and Benefits

- 4 Genuine 1092571000 Oil Cooler vs. Non-Genuine Alternatives

- 5 Technical Specifications

- 6 Installation Steps

- 7 Frequently Asked Questions (FAQs)

- 8 Conclusion

- 9 More Atlas Copco Cooler Parts

- 10 Inquiry Now

Why Your Compressor Needs a Robust Oil Cooler

The oil cooler plays a truly vital role within an air compressor’s ecosystem. It functions as a specialized heat exchanger, actively removing excess heat from the compressor lubricant before the oil recirculates through the system. This heat removal process remains critical for several reasons. Firstly, maintaining optimal oil temperature directly preserves the lubricant’s properties, preventing thermal breakdown, oxidation, and the formation of sludge and varnish. High oil temperatures severely degrade lubricant quality, drastically shortening its lifespan. Secondly, cool oil helps keep the air end at its designed operating temperature, preventing component stress and extending its operational life. Furthermore, efficient cooling contributes to the overall energy efficiency of the compressor, as cooler oil offers better lubricating and sealing properties, which reduces power consumption. Therefore, a robust and efficient oil cooler remains indispensable for the long-term health, reliability, and cost-effectiveness of your compressor.

Introducing the Genuine Atlas Copco Oil Cooler 1092571000

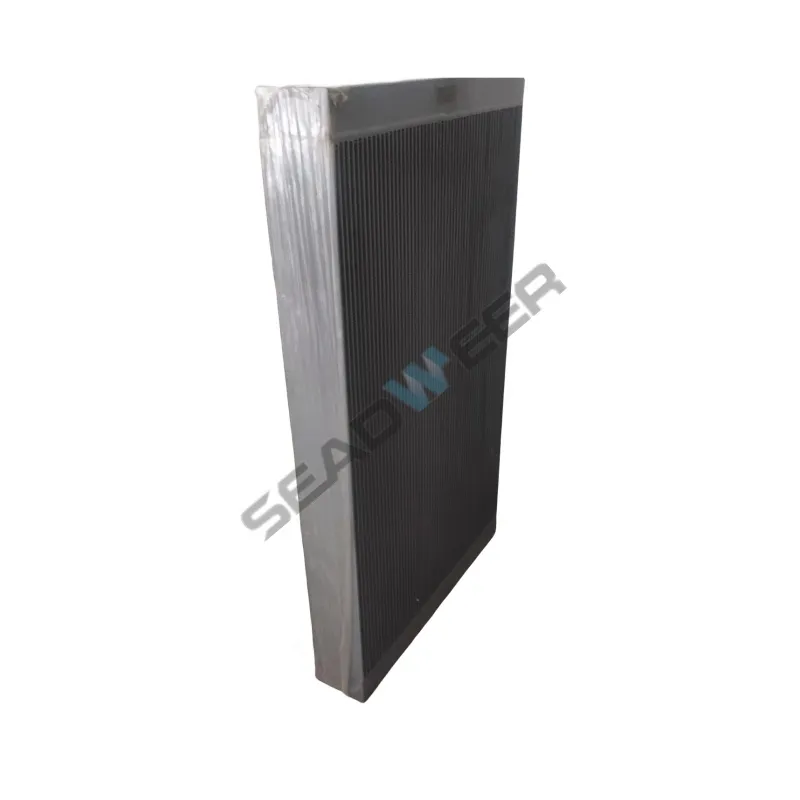

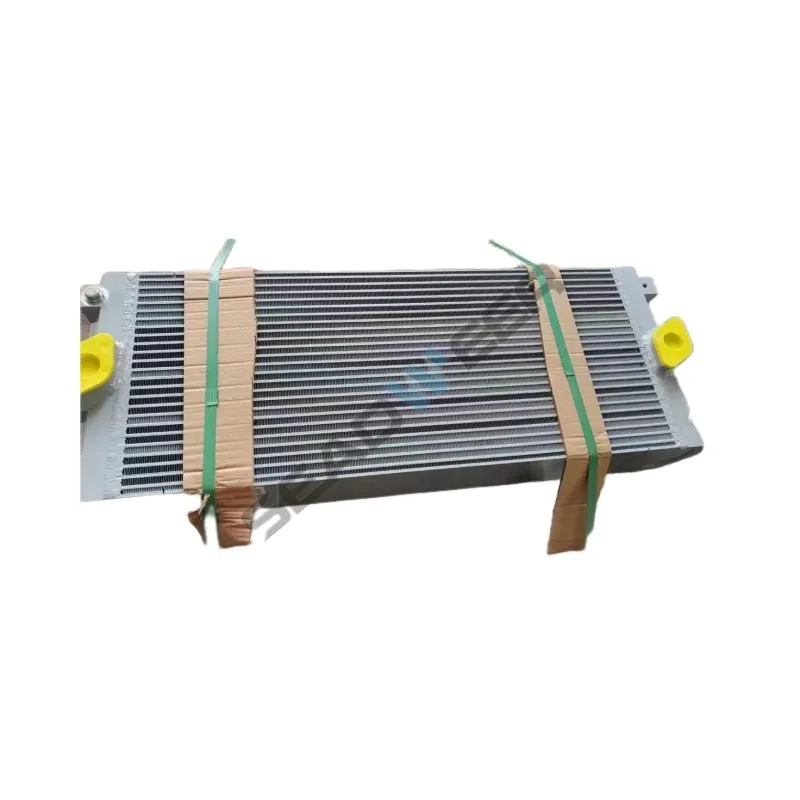

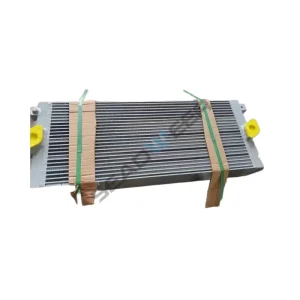

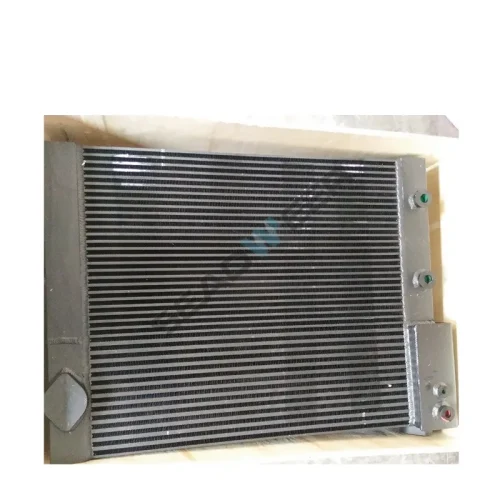

The Genuine Atlas Copco Oil Cooler, identified by part number 1092571000, is a meticulously crafted assembly specifically designed for seamless integration into designated Atlas Copco screw compressors. This part number signifies a unit engineered for precise thermal management within the compressor system. Atlas Copco manufactures this oil cooler with exceptional attention to detail, utilizing high-quality materials and advanced heat exchange technologies, such as highly efficient finned tubes or plate-fin designs. This design ensures maximum heat transfer efficiency for a given footprint. Furthermore, the cooler’s construction emphasizes durability and resistance to common industrial challenges like corrosion and fouling. Each 1092571000 oil cooler undergoes rigorous testing, which guarantees its performance and structural integrity under demanding operating conditions. As an original spare part, this oil cooler restores the compressor’s original cooling capabilities, ensuring optimal oil temperatures and, consequently, peak system performance.

Key Features and Benefits

Opting for the Genuine Atlas Copco Oil Cooler 1092571000 delivers a range of significant benefits that directly impact your compressor’s long-term performance and operational costs. Firstly, its superior heat transfer efficiency effectively dissipates heat from the lubricant, ensuring the oil remains within its optimal temperature range. This action directly extends the lifespan of the compressor oil, reducing replacement frequency and associated costs. Secondly, Atlas Copco utilizes robust construction materials and advanced manufacturing techniques, which results in exceptional durability and resistance to wear, corrosion, and vibration. This significantly extends the unit’s service life. Furthermore, the cooler’s precise engineering minimizes pressure drop across the cooling circuit, which helps maintain system efficiency and reduces energy consumption. Ultimately, investing in this genuine oil cooler secures your compressor’s reliability, maximizes its operational efficiency, and ensures long-term cost savings by protecting vital internal components.

Genuine 1092571000 Oil Cooler vs. Non-Genuine Alternatives

Choosing the Genuine Atlas Copco Oil Cooler 1092571000 over non-genuine alternatives is a critical decision that profoundly impacts your compressor’s performance, lifespan, and overall operational costs. Non-genuine coolers may offer a lower initial price, but their hidden costs often outweigh any perceived savings through reduced efficiency, increased maintenance, and potential damage to other expensive components.

| Feature | Genuine Atlas Copco 1092571000 Oil Cooler | Non-Genuine Alternatives |

| Heat Transfer Efficiency | Optimized for maximum heat removal per kW | Lower efficiency, leading to higher oil temperatures |

| Material Quality | High-grade, corrosion-resistant alloys for durability | Inferior or inconsistent materials, prone to corrosion/leaks |

| Manufacturing Precision | Exact dimensions, optimal flow pathways | Imprecise dimensions, poor fit, restrictive flow |

| Pressure Drop | Engineered for minimal pressure restriction | Higher pressure drop, reducing system efficiency |

| Corrosion Resistance | Designed for longevity in industrial environments | Susceptible to premature corrosion, leading to leaks |

| Lifespan | Engineered for extended operational life | Significantly shorter lifespan, prone to failure |

| Fit & Alignment | Perfect, seamless integration | May require modifications, leading to stress or leaks |

| Warranty | Maintains equipment warranty (check terms) | Can void equipment warranty, no manufacturer support |

| Reliability | Reduces risk of overheating and component damage | Higher risk of system failure and costly repairs |

This comparison highlights that genuine oil coolers are the result of extensive research, development, and stringent quality control processes. Non-genuine parts, conversely, often fall short in critical areas, risking premature degradation, increased energy consumption, and ultimately, a higher total cost of ownership due to accelerated component degradation and unexpected downtime.

Technical Specifications

The Genuine Atlas Copco Oil Cooler 1092571000 adheres to a specific set of highly precise technical parameters that define its performance capabilities, dimensions, and material composition. These specifications ensure it functions flawlessly within the compressor cooling system and delivers the expected heat dissipation. While the precise, detailed engineering specifications are proprietary to Atlas Copco, the table below outlines representative technical characteristics typical of a high-quality oil cooler designed for industrial screw compressor applications. These properties contribute directly to its efficiency, durability, and operational limits.

| Parameter | Representative Characteristic / Value |

| Cooler Type | Plate-fin or Tube-fin design |

| Heat Exchange Medium | Compressor Oil (Primary) vs. Air (Secondary) |

| Material (Core) | Aluminum Alloy or Copper Finned |

| Material (Housing) | Aluminum or Steel |

| Max Operating Pressure (Oil Side) | Up to 15 bar (217 psi) |

| Max Operating Temperature (Oil) | Up to 110°C (230°F) |

| Heat Dissipation Capacity | Specific kW or BTU/hr, matched to compressor size |

| Connections | Standardized ports for oil and air flow |

| Corrosion Resistance | Enhanced coatings or materials |

Note: These parameters are representative. The precise technical specifications for Atlas Copco Oil Cooler part number 1092571000 are defined by Atlas Copco’s engineering for its specific application.

Installation Steps

Replacing an Atlas Copco Oil Cooler 1092571000 is a precise and specialized task. It requires technical competence, adherence to safety protocols, and often involves draining fluids and handling heavy components. Incorrect installation or improper sealing can lead to oil leaks, reduced cooling efficiency, or severe compressor damage. It is absolutely imperative that this procedure be performed only by highly qualified, certified compressor technicians or authorized service personnel.

General Installation Steps (Requires Specialized Expertise & Tools):

Critical Safety Protocols:

Crucially, ensure the compressor is fully de-energized, isolated from all power sources, and properly locked out/tagged out according to established safety procedures. Relieve all internal air pressure from the system. Allow the compressor to cool completely. Drain all compressor oil into an appropriate container, as some oil will be present in the cooler.

Access and Disconnect:

Carefully remove any guards, covers, or piping that obstruct access to the old oil cooler. Disconnect all oil lines (inlet and outlet) and air ducts (if it’s an integrated cooler) from the cooler. Be prepared for residual oil spillage.

Remove Old Cooler:

Unbolt the mounting fasteners securing the old 1092571000 oil cooler to the compressor frame or manifold. Carefully lift and remove the old cooler, taking care not to damage surrounding components or spill remaining oil.

Clean Mounting Area:

Thoroughly clean the mounting surfaces on the compressor where the new cooler will sit. Remove any old gasket material, dirt, or debris to ensure a perfect seal. Inspect the area for any damage.

Prepare New Cooler:

Unpack the new, Genuine Atlas Copco Oil Cooler 1092571000. Inspect it for any transit damage. Ensure all new gaskets and O-rings are present and in perfect condition. Apply a thin film of clean compressor oil to new O-rings before installation.

Install New Cooler:

Carefully position the new cooler onto the mounting points. Secure all mounting bolts to the specified torque values, following any recommended tightening sequence. Ensure no hoses or wires are pinched during installation.

Reconnect Lines:

Reconnect all oil lines and air ducts (if applicable) to the new cooler. Use new seals, gaskets, or O-rings as specified by the manual. Tighten connections securely but avoid overtightening.

Refill Oil and Pre-Checks:

Refill the compressor with the correct type and quantity of genuine Atlas Copco compressor oil. Perform a thorough visual inspection for any loose connections or tools left inside.

Leak Testing and Commissioning:

Restore power to the compressor. Perform a controlled initial startup. Immediately check all cooler connections for any signs of oil or air leaks. Monitor oil temperature and system pressures closely during operation. Address any leaks or abnormal readings immediately.

Disclaimer: This guide is a simplified overview. Replacement of an Atlas Copco compressor oil cooler is a complex procedure requiring specialized tools, precise measurements, factory-level expertise, and extensive technical training. It must only be performed by certified and authorized Atlas Copco service technicians following all manufacturer guidelines and safety regulations. Attempting this without proper training can result in severe injury, catastrophic equipment damage, and voided warranties.

Frequently Asked Questions (FAQs)

Q1: What is the primary function of the Atlas Copco Oil Cooler 1092571000? A1: The primary function of this oil cooler is to remove excess heat from the compressor’s lubricating oil, ensuring the oil remains at an optimal operating temperature for lubrication, sealing, and cooling the air end.

Q2: Why is it crucial to use a genuine 1092571000 Oil Cooler? A2: A genuine oil cooler guarantees optimal heat transfer efficiency, precise fit, durable materials, and resistance to corrosion, ensuring it effectively protects your compressor’s vital components and maintains system efficiency.

Q3: How often should I inspect or replace my compressor’s oil cooler? A3: Regular inspections (e.g., for leaks, fouling, external damage) are crucial. Replacement intervals vary depending on operating conditions, but typically occur during major service intervals or upon detection of reduced cooling efficiency or leaks. Always consult your manual.

Q4: What are the risks of using a non-genuine oil cooler? A4: Non-genuine coolers may have lower heat transfer efficiency, leading to overheating. They might also feature inferior materials that corrode or leak prematurely, causing oil loss, system contamination, and severe damage to the compressor.

Q5: How does an efficient oil cooler impact compressor energy consumption? A5: An efficient oil cooler helps maintain optimal oil viscosity, which reduces friction within the air end. It also keeps operating temperatures stable. Both factors contribute to reduced energy consumption and improved overall compressor efficiency.

Conclusion

The Genuine Atlas Copco Oil Cooler 1092571000 is an indispensable element for ensuring the long-term health, efficiency, and reliability of your Atlas Copco air compressor. Its precision engineering and robust construction provide superior heat dissipation, directly contributing to extended lubricant life, reduced operational costs, and maximized equipment uptime. By choosing this authentic cooling component from a professional Atlas Copco air compressor parts supplier like Seadweer, you guarantee the uncompromising quality and exact fit your compressor needs. This action safeguards your investment and secures the uninterrupted performance of your air compression system. Trusting genuine components for the very heart of your machine ultimately translates to superior operational value and peace of mind.

More Atlas Copco Cooler Parts

If you need other cooler parts, we provide more models in the table below or you can submit your requirements to us directly.

| 6243726200 | COOLER AIR RLR 550 A | 6243-7262-00 |

| 6243719600 | COOLER 60/75 | 6243-7196-00 |

| 6243719500 | COOLER 50 AKG | 6243-7195-00 |

| 6243719400 | COOLER RLR 40 | 6243-7194-00 |

| 6243713201 | COOLER AIR 75KW RLR | 6243-7132-01 |

| 6231648200 | GASKET, INTERCOOLER, | 6231-6482-00 |

| 6231647600 | GASKET, INTERCOOLER, | 6231-6476-00 |

| 6231644600 | GASKET, AFTERCOOLER, | 6231-6446-00 |

| 2911010000 | PNS AFTERCOOLER II K | 2911-0100-00 |

| 2911009900 | PNS AFTERCOOLER I KI | 2911-0099-00 |

| 2911009800 | PNS INTERCOOLER II K | 2911-0098-00 |

| 2911009700 | PTS AFTERCOOLER II K | 2911-0097-00 |

| 2911008700 | AFTERCOOLER KIT | 2911-0087-00 |

| 2911008600 | INTERCOOLER KIT | 2911-0086-00 |

| 2906097400 | GA90/160 A COOLER KI | 2906-0974-00 |

| 2906096600 | GA90/110 W COOLER KI | 2906-0966-00 |

| 2906081300 | COOLER SERVICE KIT Z | 2906-0813-00 |

| 2906079700 | ZR160/275 COOLER CLE | 2906-0797-00 |

| 2906074600 | COOLER SERVICE KIT Z | 2906-0746-00 |

| 2906073400 | COOLER KIT ZR160VSD | 2906-0734-00 |

| 2906073300 | AFTERCOOLER KIT ZR16 | 2906-0733-00 |

| 2906073200 | INTERCOOLER KIT ZR16 | 2906-0732-00 |

| 2906069500 | GA315A VSD COOLER KI | 2906-0695-00 |

| 2906068400 | AFTERCOOLER KIT ZE4 | 2906-0684-00 |

| 2903102000 | COMBI-COOLER | 2903-1020-00 |

| 2903101900 | COOLER-COMBI | 2903-1019-00 |

| 2903101800 | COOLER-COMBI | 2903-1018-00 |

| 2903101400 | OIL COOLER | 2903-1014-00 |

| 2902009500 | EWD INTERCOOLER | 2902-0095-00 |

| 2901186700 | COOLER KIT ZT(Z2008) | 2901-1867-00 |

| 2901115500 | COOLER KIT | 2901-1155-00 |

| 2901111400 | COOLER KIT | 2901-1114-00 |

| 2901111300 | COOLER KIT | 2901-1113-00 |

| 2900207200 | AIR AFTERCOOLER GA20 | 2900-2072-00 |

| 2255169300 | COOLER-OIL | 2255-1693-00 |

| 2255072805 | AFTERCOOLER TD08 | 2255-0728-05 |

| 2254673301 | COOLER-OIL | 2254-6733-01 |

| 2254673300 | COOLER-OIL | 2254-6733-00 |

| 2254108300 | AFTERCOOLER | 2254-1083-00 |

| 2254074900 | AFTERCOOLER | 2254-0749-00 |

| 2254074800 | COOLER-OIL | 2254-0748-00 |

| 2253574400 | COOLER-OIL | 2253-5744-00 |

| 2253574200 | AFTERCOOLER | 2253-5742-00 |

| 2253574100 | COOLER-COMBI | 2253-5741-00 |

| 2253497300 | COOLER | 2253-4973-00 |

| 2253497200 | INTERCOOLER | 2253-4972-00 |

| 2253497100 | AFTERCOOLER | 2253-4971-00 |

| 2253440000 | COOLER-OIL | 2253-4400-00 |

| 2253384400 | COOLER-OIL | 2253-3844-00 |

| 2252984400 | COOLER-OIL | 2252-9844-00 |

Anonymous –

Genuine Atlas Copco parts really do last longer!

Installed the 1092571000 cooler on our GA160 and it dropped operating temps by 18°C! After 6 months of 24/7 use, no clogging or leaks. Genuine Atlas Copco parts really do last longer.