Effective temperature management remains absolutely paramount for the reliable operation and extended lifespan of any industrial air compressor. Within oil-flooded screw compressors, two primary heat loads require constant attention: the hot compressed air exiting the air end and the heated lubricating oil circulating through the system. A well-designed cooling solution efficiently tackles both challenges. Among these vital components, the Genuine Atlas Copco Combi Cooler, identified by part number 1092200286, stands as a benchmark of integrated engineering excellence. This single, highly efficient unit simultaneously cools both the compressed air and the compressor oil, ensuring optimal operating temperatures for all vital components.

When your compressor’s cooling system requires maintenance or component replacement due to wear, age, or malfunction, installing a genuine unit is not merely a recommendation; it is an absolute necessity for protecting your investment and ensuring continued productivity and air quality. For businesses requiring this authentic, high-precision cooling component, Seadweer stands as a professional and trusted supplier specializing in genuine air compressor parts. Consequently, choosing Seadweer ensures you acquire a cooler manufactured to the exact specifications and uncompromising quality standards set by Atlas Copco.

Contents

Why Integrated Cooling is Crucial

The Combi Cooler plays a truly vital role within an air compressor’s ecosystem by addressing two critical cooling needs simultaneously. It functions as a specialized heat exchanger, actively removing excess heat from both the compressor lubricant and the newly compressed air. This integrated heat removal process remains critical for several reasons. Firstly, maintaining optimal oil temperature directly preserves the lubricant’s properties, preventing thermal breakdown, oxidation, and the formation of sludge and varnish. High oil temperatures severely degrade lubricant quality, drastically shortening its lifespan. Secondly, cooling the compressed air (aftercooling) significantly reduces its temperature before it enters downstream equipment, such as air dryers or production machinery. This action condenses a substantial amount of water vapor, transforming it into liquid condensate that can then be easily drained. Furthermore, efficient cooling contributes to the overall energy efficiency of the compressor, as cooler oil offers better lubricating and sealing properties, and cooler air is denser, which also reduces power consumption in some scenarios. Therefore, a robust and efficient combi cooler remains indispensable for the long-term health, reliability, air quality, and cost-effectiveness of your compressor.

Introducing the Combi Cooler 1092200286

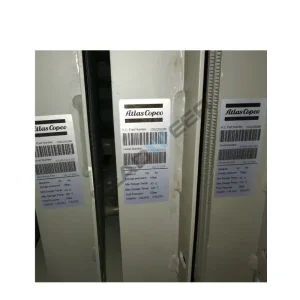

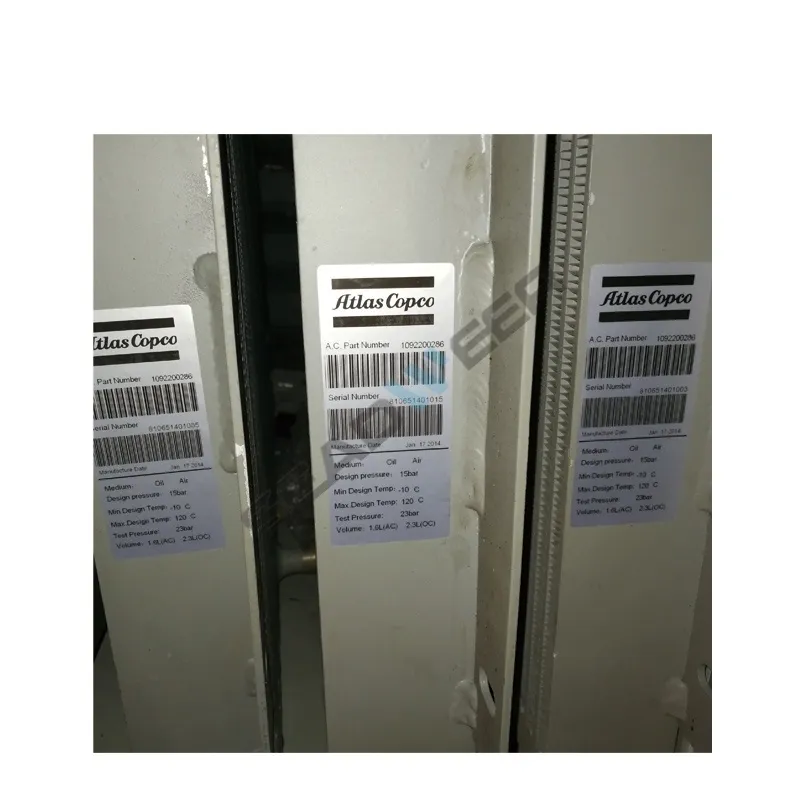

The Genuine Atlas Copco Combi Cooler, identified by part number 1092200286, is a meticulously crafted assembly specifically designed for seamless integration into designated Atlas Copco screw compressors. This part number signifies a unit engineered for precise thermal management within the compressor system, handling both oil and air cooling. Atlas Copco manufactures this combi cooler with exceptional attention to detail, utilizing high-quality materials and advanced heat exchange technologies, such as highly efficient finned tubes or plate-fin designs, specifically optimized for dual-stream cooling. This design ensures maximum heat transfer efficiency for a given footprint. Furthermore, the cooler’s robust construction emphasizes durability and resistance to common industrial challenges like corrosion and fouling, which are common due to the presence of moisture and oil. Each 1092200286 combi cooler undergoes rigorous testing, which guarantees its performance and structural integrity under demanding operating conditions. As an authentic component, this combi cooler restores the compressor’s original cooling capabilities, ensuring optimal oil temperatures, effective moisture removal, and, consequently, peak system performance.

Key Advantages of the Genuine 1092200286 Combi Cooler

Opting for the Genuine Atlas Copco Combi Cooler 1092200286 delivers a range of significant benefits that directly impact your compressor’s long-term performance and operational costs.

- Optimized Heat Transfer Efficiency: The integrated design and high-quality materials ensure maximum heat dissipation from both the compressor oil and compressed air. This maintains optimal operating temperatures for all critical components.

- Integrated Design for Space & Simplicity: Combining the oil cooler and aftercooler into a single unit saves valuable floor space within the compressor package. It also simplifies piping and reduces potential leak points compared to separate units.

- Superior Material Durability: Atlas Copco uses robust, corrosion-resistant materials (e.g., aluminum or copper) specifically chosen for their thermal conductivity and resistance to industrial environments. This extends the cooler’s service life.

- Reduced Energy Consumption: Efficient heat exchange and low pressure drop across both the oil and air sides of the cooler contribute to lower energy consumption. This reduces the overall power required to operate the compressor.

- Enhanced Condensate Removal: Effective aftercooling significantly lowers the dew point of the compressed air, causing more water vapor to condense into liquid. This action reduces the load on downstream air dryers and improves overall air quality.

- Exact Compatibility & Reliability: Designed and tested by Atlas Copco for specific compressor models, this cooler ensures a perfect fit, optimal thermal performance, and unwavering reliability. This maintains system integrity and potentially preserves the compressor’s warranty.

Genuine Cooler vs. Non-Genuine Alternatives

Choosing the Genuine Atlas Copco Combi Cooler 1092200286 over non-genuine alternatives is a critical decision that profoundly impacts your compressor’s performance, lifespan, and overall operational costs. Non-genuine coolers may offer a lower initial price, but their hidden costs often outweigh any perceived savings through reduced efficiency, increased maintenance, and potential damage to other expensive components.

| Feature | Genuine Atlas Copco 1092200286 Combi Cooler | Non-Genuine Alternatives |

| Heat Transfer Efficiency | Optimized for maximum dual-stream heat removal | Lower efficiency, leading to higher oil and air temperatures |

| Material Quality | High-grade, corrosion-resistant alloys for durability | Inferior or inconsistent materials, prone to corrosion/leaks |

| Manufacturing Precision | Exact dimensions, optimal fin/tube spacing | Imprecise dimensions, poor fit, restrictive flow |

| Pressure Drop (Air/Oil) | Engineered for minimal pressure restriction | Higher pressure drop, reducing system efficiency |

| Corrosion Resistance | Designed for longevity in humid/oily environments | Susceptible to premature corrosion, leading to leaks |

| Lifespan | Engineered for extended operational life | Significantly shorter lifespan, prone to failure |

| Fit & Alignment | Perfect, seamless integration | May require modifications, leading to stress or leaks |

| Condensate Removal | Maximized due to efficient aftercooling | Less effective, leading to more moisture downstream |

| Warranty | Maintains equipment warranty (check terms) | Can void equipment warranty, no manufacturer support |

This comparison clearly demonstrates that genuine combi coolers are the result of extensive research, development, and stringent quality control processes. Non-genuine parts, conversely, often fall short in critical areas, risking premature degradation, increased energy consumption, and ultimately, a higher total cost of ownership due to accelerated component degradation, poor air quality, and unexpected downtime.

Installation Steps for 1092200286 Combi Cooler

Replacing an Atlas Copco Combi Cooler 1092200286 is a precise and specialized task. It requires technical competence, adherence to safety protocols, and often involves draining fluids and handling heavy components. Incorrect installation or improper sealing can lead to oil leaks, reduced cooling efficiency, or severe compressor damage. It is absolutely imperative that this procedure be performed only by highly qualified, certified compressor technicians or authorized service personnel.

General Installation Steps (Requires Specialized Expertise & Tools):

Critical Safety Protocols

Crucially, ensure the compressor is fully de-energized, isolated from all power sources, and properly locked out/tagged out according to established safety procedures. Relieve all internal air pressure from the system. Allow the compressor to cool completely. Drain all compressor oil into an appropriate container, as some oil will be present in the cooler. Drain any condensate from the aftercooler section.

Access and Disconnect

Carefully remove any guards, covers, or piping that obstruct access to the old combi cooler. Disconnect all oil lines (inlet and outlet) and air ducts (inlet from air end, outlet to receiver/dryer) from the cooler. Be prepared for residual oil and condensate spillage.

Remove Old Cooler

Unbolt the mounting fasteners securing the old 1092200286 combi cooler to the compressor frame. Carefully lift and remove the old cooler, taking care not to damage surrounding components or spill remaining fluids.

Clean Mounting Area

Thoroughly clean the mounting surfaces on the compressor where the new cooler will sit. Remove any old gasket material, dirt, or debris to ensure a perfect seal. Inspect the area for any damage.

Prepare New Cooler

Unpack the new, Genuine Atlas Copco Combi Cooler 1092200286. Inspect it for any transit damage. Ensure all new gaskets and O-rings are present and in perfect condition. Apply a thin film of clean compressor oil to new O-rings before installation.

Install New Cooler

Carefully position the new cooler onto the mounting points. Secure all mounting bolts to the specified torque values, following any recommended tightening sequence. Ensure no hoses or wires are pinched during installation.

Reconnect Lines

Reconnect all oil lines and air ducts to the new cooler. Use new seals, gaskets, or O-rings as specified by the manual. Ensure correct flow direction for air and oil. Tighten connections securely but avoid overtightening.

Refill Oil and Pre-Checks

Refill the compressor with the correct type and quantity of genuine Atlas Copco compressor oil. Perform a thorough visual inspection for any loose connections or tools left inside.

Leak Testing and Commissioning

Restore power to the compressor. Perform a controlled initial startup. Immediately check all cooler connections for any signs of oil or air leaks. Monitor oil temperature and system pressures closely during operation. Address any leaks or abnormal readings immediately.

Disclaimer: This guide is a simplified overview. Replacement of an Atlas Copco compressor combi cooler is a complex procedure requiring specialized tools, precise measurements, factory-level expertise, and extensive technical training. It must only be performed by certified and authorized Atlas Copco service technicians following all manufacturer guidelines and safety regulations. Attempting this without proper training can result in severe injury, catastrophic equipment damage, and voided warranties.

FAQs

Q1: What is the primary function of the Atlas Copco Combi Cooler 1092200286? A1: This combi cooler simultaneously cools both the compressor’s lubricating oil and the hot compressed air, ensuring optimal operating temperatures for the machine and removing most of the water vapor from the air.

Q2: Why is it crucial to use a genuine 1092200286 Combi Cooler? A2: A genuine cooler guarantees optimized heat transfer efficiency, precise fit, durable materials, and resistance to corrosion, ensuring it effectively protects your compressor’s vital components and maintains system efficiency and air quality.

Q3: How often should I inspect or clean my compressor’s combi cooler? A3: Regular inspections (e.g., for external fouling, leaks) are crucial, typically every 2000-4000 operating hours or as recommended in your compressor manual. Cleaning frequency depends on the operating environment’s dustiness.

Q4: What are the risks of using a non-genuine combi cooler? A4: Non-genuine coolers may have lower heat transfer efficiency, leading to overheating of both oil and air. They might also feature inferior materials that corrode or leak prematurely, causing fluid loss, system contamination, and severe damage to other components.

Q5: How does a combi cooler contribute to air quality? A5: By significantly cooling the compressed air (aftercooling), the combi cooler causes a large amount of water vapor to condense into liquid. This liquid can then be drained, greatly reducing the moisture content in the air before it reaches the air dryer or downstream equipment.

More Cooler Parts List

| 3002604600 | 2 stage Cooler clean kit | 3002-6046-00 |

| 3002604611 | 3 stage Cooler clean kit | 3002-6046-11 |

| 3002604640 | 2 stage Cooler clean kit | 3002-6046-40 |

| 3002604650 | 3 stage Cooler clean kit | 3002-6046-50 |

| 3002604890 | WATER COOLER KIT | 3002-6048-90 |

| 3002604970 | OIL COOLER SERVICE KIT | 3002-6049-70 |

| 3002605170 | INTER COOLER SEAL KIT | 3002-6051-70 |

| 3002605180 | AFTER COOLER SEAL KIT | 3002-6051-80 |

| 3002605204 | COOLER CORE | 3002-6052-04 |

| 3002605205 | COOLER CORE | 3002-6052-05 |

| 3002605270 | Cooler Service kit | 3002-6052-70 |

| 3002605600 | Inter cooler service kit | 3002-6056-00 |

| 3002605710 | Cooler cleaning kit | 3002-6057-10 |

| 3002605800 | COOLER KIT-FILME COMPRESSOR | 3002-6058-00 |

| 6229016200 | COOLER KIT GV 34 | 6229-0162-00 |

| 6229017500 | COOLER KIT NS 29S | 6229-0175-00 |

| 6229018700 | COOLER KIT NS 39 | 6229-0187-00 |

| 6229020000 | COOLER KIT NS 59/S-B 7900 | 6229-0200-00 |

| 6229020400 | AFTERCOOLER KIT B28/28/38 | 6229-0204-00 |

| 6231644600 | AFTERCOOLER GASKET | 6231-6446-00 |

| 6231648200 | INTERCOOLER GASKET | 6231-6482-00 |

| 6243722800 | COOLER COMBI | 6243-7228-00 |

| 6243722900 | COOLER COMBI | 6243-7229-00 |

| 6243723000 | COOLER COMBI | 6243-7230-00 |

| 6243733100 | AIR COOLER RLR 100 | 6243-7331-00 |

| 6243733200 | COOLER AFTER | 6243-7332-00 |

| 6243733300 | COOLER OIL | 6243-7333-00 |

| 6243733400 | AIR COOLER RLR 125/150 | 6243-7334-00 |

| 6243733500 | COOLER OIL | 6243-7335-00 |

| 6243733600 | OIL COOLER RLR 150 | 6243-7336-00 |

| 6243733700 | COOLER AFTER | 6243-7337-00 |

| 6243733800 | OIL COOLER RLR 150/180 | 6243-7338-00 |

| 6243733900 | AIR COOLER RLR 220 | 6243-7339-00 |

| 6243734000 | COOLER | 6243-7340-00 |

| 6243734100 | COMBICOOLER RLR/CSB 26OIL CH | 6243-7341-00 |

| 6275613600 | COOLER CORNER CSB/R | 6275-6136-00 |

| 6275613610 | COOLER CORNER CSB/RLR 15/25 | 6275-6136-10 |

| 6275613910 | DEFLECTOR COOLER CSB 15/40 | 6275-6139-10 |

| 6996012153 | FLANGE, COOLER | 6996-0121-53 |

| 6996012694 | COOLER, AIR+OIL, E18. | 6996-0126-94 |

| 6996021000 | COOLER, E5 | 6996-0210-00 |

| 9096614700 | OIL COOLER | 9096-6147-00 |

| 9098211300 | INTER COOLER FOR HN2T-215 N | 9098-2113-00 |

| 9098211500 | AFTERCOOLER FOR HN2T-215 NP | 9098-2115-00 |

| 9098899500 | HOSE OIL COOLER OUTLET | 9098-8995-00 |

| 9098899600 | HOSE OIL COOLER INLET | 9098-8996-00 |

| 9106077425 | COOLER SUPPORT | 9106-0774-25 |

| 9771020641 | HDH-20 vertical after cooler | 9771-0206-41 |

| 9771020642 | HDH-30 vertical after cooler | 9771-0206-42 |

| 9771020643 | HDH-45 vertical after cooler | 9771-0206-43 |

Conclusion

The Genuine Atlas Copco Combi Cooler 1092200286 is an indispensable element for ensuring the long-term health, efficiency, and reliability of your Atlas Copco air compressor. Its precision engineering and integrated design provide robust thermal management for both lubricant and compressed air, directly contributing to extended component life, reduced operational costs, and maximized equipment uptime. By choosing this authentic cooling component from a professional supplier like Seadweer, you guarantee the uncompromising quality and exact fit your compressor needs. This action safeguards your investment and secures the uninterrupted performance of your air compression system. Trusting genuine components for the very heart of your machine ultimately translates to superior operational value and peace of mind.

Anonymous_Buyer –

Excellent performance and reliability!

This genuine Atlas Copco 1092200286 cooler significantly improved my compressor’s cooling efficiency. Installation was straightforward, and the temperature control is outstanding. After six months of heavy-duty operation, it maintains consistent performance without any issues. Definitely worth the investment for maintaining optimal compressor operation.