In industrial production and everyday applications, compressed air is an essential source of energy. Selecting the right air compressor not only affects operational efficiency but also impacts operational costs and product quality. Today, the two main types of compressors on the market are piston compressors and screw compressors. This article will explore the working principles, performance characteristics, application scenarios, and respective pros and cons of piston compressors and screw compressors to help you make an informed decision based on your actual needs.

Contents

Comparison of Working Principles

Piston Compressors

Piston compressors operate by using a crankshaft to drive a piston, which moves back and forth within a cylinder to draw in and compress air. This type of compressor is known for its simple structure and low manufacturing cost. It is suitable for applications with intermittent air demand and relatively high pressure requirements. However, due to its many moving parts, it tends to produce significant vibration and noise during operation.

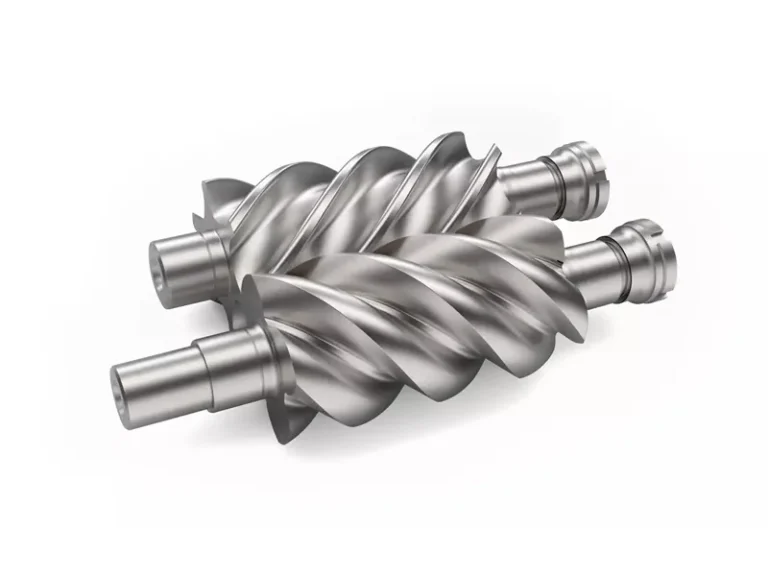

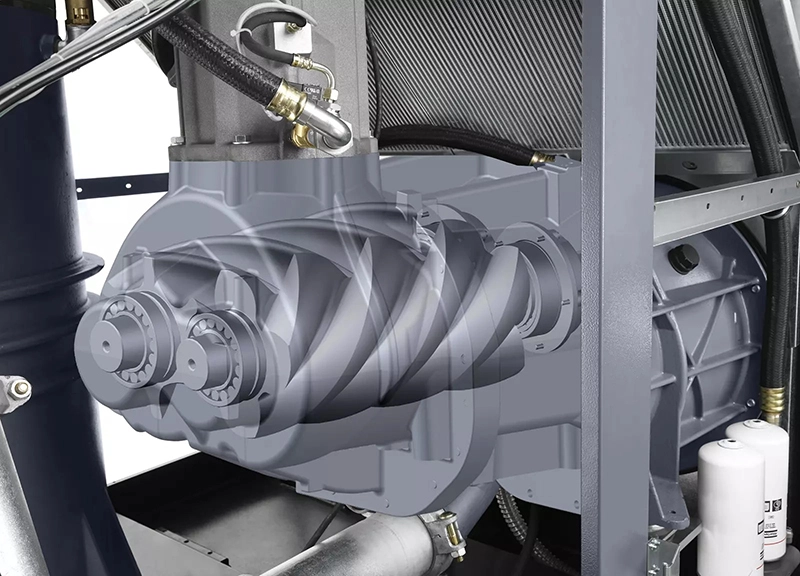

Screw Compressors

Screw compressors use a pair of intermeshing helical rotors to compress air continuously as the rotors rotate. This method offers a smooth and steady compression process, making it ideal for applications requiring a constant, uninterrupted air supply. Additionally, screw compressors are compact, quieter during operation, and require less frequent maintenance.

Performance Comparison

Energy Efficiency

Screw compressors outperform piston compressors in energy efficiency. Typically, piston compressors deliver 3 to 4 cubic feet per minute (CFM) of airflow per horsepower (HP), while screw compressors can achieve 4 to 5 CFM/HP. This means screw compressors deliver more compressed air for the same power input, reducing energy consumption.

Duty Cycle

Piston compressors usually have a duty cycle of 60-70%, meaning they can only operate for about 36 to 42 minutes per hour before needing to cool down. Screw compressors, on the other hand, are designed for continuous operation and can achieve a 100% duty cycle, making them suitable for 24/7 production environments.

Air Quality

Due to the high temperatures generated during compression, piston compressors tend to produce air with higher moisture and oil content, requiring additional drying and filtration equipment. Screw compressors operate at lower temperatures and are often equipped with built-in coolers, resulting in cleaner air that meets the requirements of sensitive applications.

Maintenance and Durability

Piston compressors are relatively easy to maintain due to their simple design. However, because they contain many moving parts, they wear out more quickly and require more frequent servicing. Screw compressors have fewer moving components, which results in lower wear and longer maintenance intervals, offering higher reliability during long-term operation.

Noise and Space Requirements

Piston compressors are noisy and generate considerable vibration during operation. They usually need to be installed away from work areas and require vibration-dampening foundations. Screw compressors, by contrast, operate more quietly and smoothly, allowing for installation closer to the workspace, thereby saving space and reducing installation costs.

Cost Analysis

Initial Investment

Piston compressors are more affordable to purchase, making them a suitable option for small businesses or startups with limited budgets. Screw compressors, though more expensive initially, provide greater long-term economic benefits due to their efficiency and lower maintenance costs.

Operating Costs

Despite the lower upfront cost of piston compressors, their energy efficiency is lower, and they require more frequent maintenance, leading to higher long-term operating costs. Screw compressors, with their superior efficiency and durability, are more cost-effective for businesses with consistent compressed air demands.

Recommended Application Scenarios

Piston Compressors

- Small workshops, repair shops, tire service stations, and other scenarios with intermittent air demand

- Companies with tight budget constraints

- Applications with minimal requirements for air quality

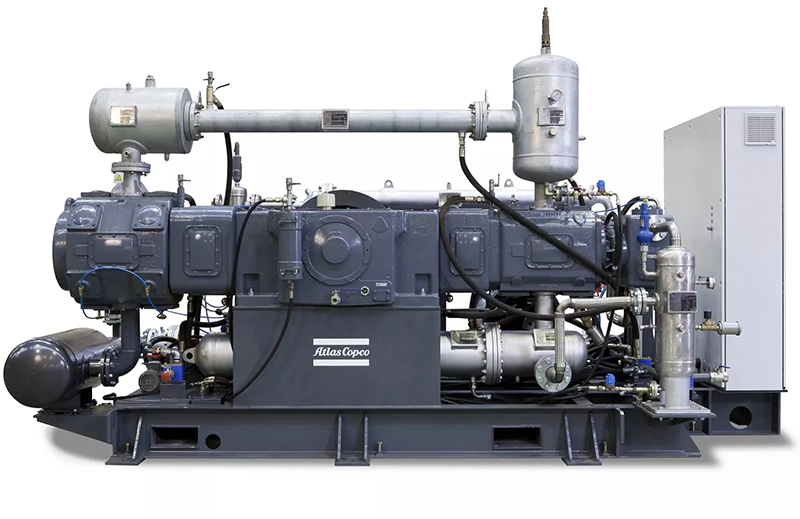

Screw Compressors

- Industries such as manufacturing, food processing, and pharmaceuticals with continuous air demand

- Applications that require high-quality compressed air, such as electronics and medical fields

- Businesses focusing on long-term operational cost savings and equipment reliability

Selection Advice

When choosing an air compressor, consider the following factors:

- Application requirements: Understand the purpose of the compressed air, required pressure, and airflow.

- Run time: Estimate the daily operating hours and working cycle.

- Air quality: Determine the quality of air needed for your process.

- Budget planning: Evaluate both the initial investment and the long-term operational costs.

- Space and noise limitations: Choose equipment suitable for your installation environment.

Conclusion

Both piston and screw compressors have their own advantages. Choosing the right type depends on your specific needs, budget, and long-term goals. For businesses with intermittent air demand and limited budgets, piston compressors offer a practical solution. For those requiring continuous, high-quality air supply, screw compressors provide higher efficiency and reliability. Before making a final decision, it is advisable to consult with professional compressor suppliers to receive tailored advice and ensure that you invest in the most suitable equipment for your operation.

Reference

1.Rotary Screw vs Piston Compressor: What’s the best solution?

2.Choosing between a screw compressor and piston air compressor