When selecting a rotary screw compressor, one of the most important decisions is choosing between an oil-injected (also called oil-lubricated) and an oil-free model. Both types serve the same fundamental purpose—supplying compressed air—but they differ significantly in design, operation, cost, and suitable applications.

This article explores the key differences between oil-injected and oil-free rotary screw air compressors to help you make an informed decision for your business.

Contents

- 1 What Is an Oil-injected Rotary Screw Compressor?

- 2 What Is an Oil-free Rotary Screw Compressor?

- 3 Key Differences Between Oil-injected and Oil-free Compressors

- 4 Which One Should You Choose?

- 5 Industry Applications

- 6 Long-term Considerations

- 7 Conclusion

- 8 Reference

- 9 Related Oil-inject Air Compressors

- 10 Related Oil-free Air Compressors

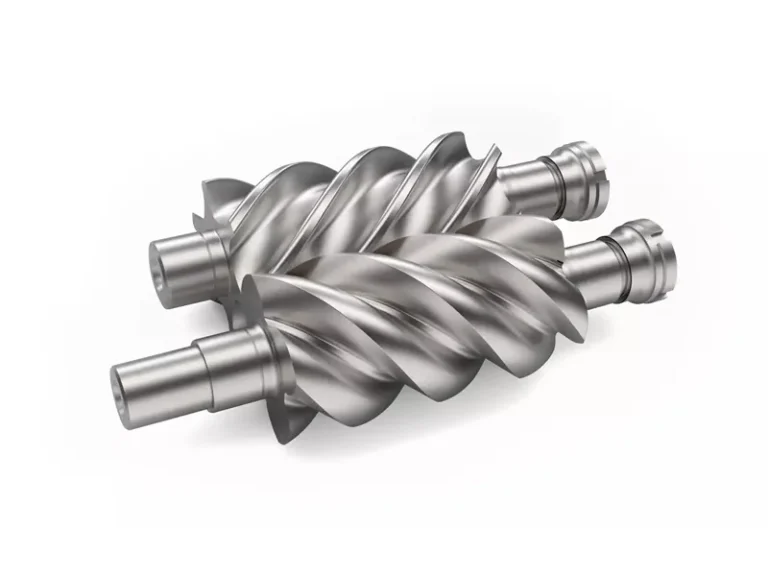

What Is an Oil-injected Rotary Screw Compressor?

Oil-injected air compressors use a small amount of lubricating oil that is injected into the compression chamber. This oil serves three main purposes:

- Lubricates the rotors for smoother operation

- Seals the gaps between the rotors to increase efficiency

- Cools the air during compression to prevent overheating

After compression, the oil-air mixture passes through a separator where most of the oil is removed and recycled. The air then continues to an aftercooler before being delivered to the application.

What Is an Oil-free Rotary Screw Compressor?

Oil-free rotary screw compressors do not use oil inside the compression chamber. Instead, they rely on:

- Precision engineering with tight rotor tolerances

- Special coatings (e.g., PTFE or ceramic)

- Alternative materials like water or air for cooling (in some designs)

These compressors deliver clean, oil-free compressed air, which is essential for sensitive industries like food, pharmaceuticals, and electronics.

Key Differences Between Oil-injected and Oil-free Compressors

| Feature | Oil-injected | Oil-free |

|---|---|---|

| Lubrication | Oil used inside the compression chamber | No oil in compression chamber |

| Air Purity | May contain oil traces (requires filtration) | 100% oil-free air output |

| Initial Cost | Lower | Higher |

| Maintenance | Regular oil changes and separator maintenance | Less frequent but more specialized service |

| Energy Efficiency | Generally more efficient | Slightly less efficient due to tighter tolerances |

| Suitable Applications | General industry, automotive, metalworks | Food, pharma, electronics, medical |

Which One Should You Choose?

Choose Oil-injected if:

- You need a reliable and cost-effective solution for general industrial use

- Your compressed air quality requirements allow minimal oil traces

- You prioritize lower initial investment and higher energy efficiency

Choose Oil-free if:

- You operate in a regulated industry where air purity is critical (ISO 8573-1 Class 0)

- You want to avoid downstream filtration and contamination risks

- You can justify the higher investment for clean air and long-term reliability

Industry Applications

| Industry | Recommended Type | Reason |

|---|---|---|

| General Manufacturing | Oil-injected | Cost-effective and efficient |

| Food & Beverage | Oil-free | No oil contamination in production |

| Pharmaceuticals | Oil-free | Complies with strict hygiene standards |

| Automotive Workshops | Oil-injected | Durable for tools and equipment |

| Electronics | Oil-free | Sensitive processes need ultra-clean air |

| Textile & Packaging | Oil-injected / Oil-free | Depends on the process and product contact |

Long-term Considerations

Total Cost of Ownership (TCO)

- Oil-injected compressors have a lower purchase price and high energy efficiency, but higher maintenance costs due to oil changes and separator replacement.

- Oil-free compressors cost more upfront but offer long-term savings in applications where oil contamination would lead to product loss or production downtime.

Environmental Impact

- Oil-free compressors are often chosen for environmentally conscious operations.

- They reduce the need for oil disposal and minimize the risk of oil leaks or contamination.

Conclusion

Choosing between an oil-injected and oil-free rotary screw compressor depends on your industry, air quality requirements, and budget. Oil-injected compressors are ideal for general industrial use, while oil-free models are essential for clean, contamination-free operations. Understanding the differences will help you invest in the right technology for maximum performance and peace of mind.

Reference

1.Oil-free vs. Oil-injected air compressors. https://www.atlascopco.com/en-sg/rental/resources/blog/oil-free-vs-oil-injected-air-compressors

2.The Difference Between Oil-Injected and Oil-Free Rotary Screw Compressors. https://www.airmac.com/difference-oil-injected-oil-free-rotary-screw-compressors/

Related Oil-inject Air Compressors

-

Atlas Copco Air Compressor G-Series

Price range: $8,000.00 through $10,000.00 -

Atlas Copco Air Compressor GA11+ – 30 FF

Price range: $880.00 through $1,800.00 -

Atlas Copco Air Compressor GA110VSD

Price range: $6,800.00 through $10,000.00 -

Atlas Copco Air Compressor GA132

Price range: $6,800.00 through $10,000.00

Related Oil-free Air Compressors

-

Atlas Copco Air Compressors SF8+ SF11+ SF15+ SF17+ SF22+

Price range: $10,000.00 through $30,000.00 -

Atlas Copco AQ 15-55 VSD Oil-free Water-Injected Compressors

Price range: $10,000.00 through $30,000.00 -

Atlas Copco Oil Free Scroll Air Compressor SF4ff

Price range: $3,800.00 through $6,000.00 -

Atlas Copco Screw compressor GX 3 FF

Price range: $5,000.00 through $6,000.00