Rotary screw compressor serve as indispensable power equipment in modern industrial production, where their stable operation directly impacts production efficiency and product quality. Understanding the working principles, functional characteristics, and maintenance requirements of their core components is crucial for ensuring long-term efficient equipment operation.

Contents

- 1 Air Filtration System: The First Line of Defense for Clean Air

- 2 Compression Core: Rotary Screw Element

- 3 Lubrication and Cooling System

- 4 Bearing System: Precision Motion Assurance

- 5 Valve System: Key to Precise Control

- 6 Power and Control Systems

- 7 Sealing System: Airtightness Guarantee

- 8 Maintenance Recommendations and Summary

- 9 References

Air Filtration System: The First Line of Defense for Clean Air

Inlet Air Filter

The inlet air filter is positioned at the forefront of the compressor system, bearing the critical responsibility of filtering impurities from ambient air. For oil-lubricated models, the air filter must not only remove dust particles from the intake air but also handle moisture and oil residue from opening valves and cooling injection processes. The performance of this component directly affects the working efficiency and service life of the entire machine.

In oil-free models, air filters are typically installed near the intake valves, forming the primary protective barrier against impurities in pressurized air. Due to their substantial filtration load, they become one of the most frequently replaced components in routine maintenance. Regular inspection and replacement of air filters not only ensure normal equipment operation but also effectively extend the service life of other internal components.

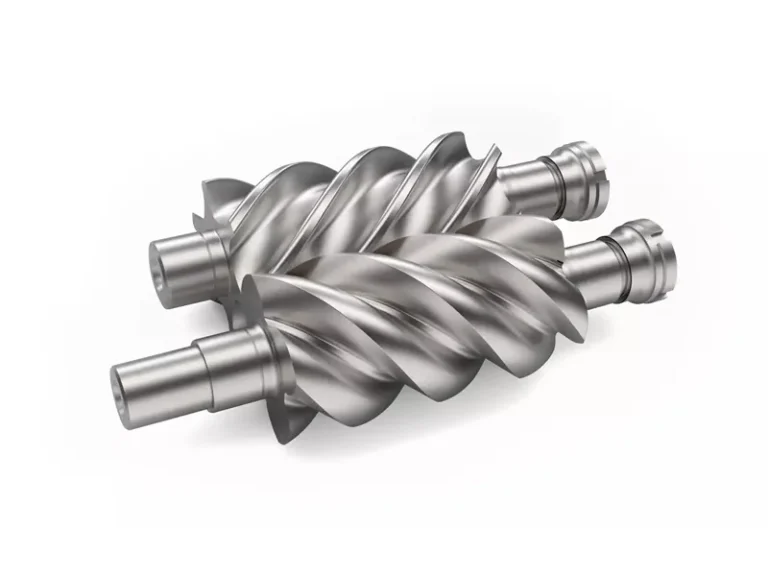

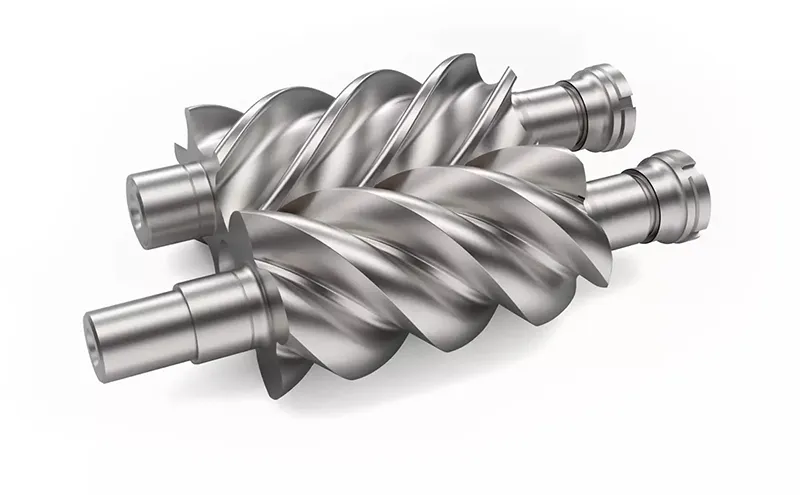

Compression Core: Rotary Screw Element

The rotary screw element represents the heart of the entire compressor system, consisting of a pair of precisely machined interlocking twin rotors. These two rotors are installed within precision-machined cylinders, achieving air compression through complementary circular rotational motion. When the equipment starts, the rotors begin operation, drawing ambient air through the intake valve.

The rotors connect to the compressor motor and begin high-speed rotation through a transmission system comprising belts, bearings, and motor drives. During rotation, air is drawn in and gradually compressed within the rotor gaps. When the rotor grooves reach the air end of their rotational stroke, the air has been compressed to the preset pressure state. Finally, the fully compressed air is released through the discharge valve into the storage tank, completing one complete compression cycle.

This design ensures continuous and stable compressed air output. It also runs with lower noise and needs less maintenance than reciprocating compressors.

Lubrication and Cooling System

Oil Filter

Oil filters play a crucial role in maintaining compressed air purity and ensuring proper lubrication and cooling functions throughout the machine. They work in coordination with the belt and pulley systems within the oil separator to ensure lubricating oil cleanliness meets equipment requirements. Modern oil filters employ spin-on designs for convenient inspection and replacement operations.

Most oil filters have bypass valves that give warnings when clogged or overheated. In such cases, the valve lets unfiltered oil enter the compression chamber. This prevents damage from oil blockage and ensures basic lubrication continues.

Related Products

-

100% Genuine Atlas Copco Oil Filter 1614874799=1614874700

Price range: $100.00 through $150.00 -

100% Original Atlas Copco Centrifuge Oil Filter 1621808500

Price range: $50.00 through $90.00 -

100% Original Ingersoll Rand 54672654 Coolant Oil Filter

Price range: $20.00 through $26.00 -

1613610590 Oil Filter for Atlas Copco Air Compressors

Price range: $30.00 through $50.00

Oil Separator

Certain compressor models require lubricating oil injection into compression chambers for cooling and lubrication functions, but simultaneously require oil separators to filter and remove excess oil from compressed air.

High temperatures are natural byproducts of equipment compression performance, making the use of lubricating oil and coolants necessary for enhancing equipment performance. However, oil separators ensure that oil does not mix with the final compressed air, guaranteeing output air purity. When oil separators wear out or equipment performance optimization is needed, timely replacement installation can be performed.

Related Products

-

100% Original 2202929400 Oil Filter Separator

Price range: $70.00 through $90.00 -

1092137320 Air Oil Separator for Atlas Copco Compressor

Price range: $20.00 through $26.00 -

1092300919 Oil Separator Parts for Atlas Copco

Price range: $80.00 through $110.00 -

1621938500 Oil Separator for Atlas Copco Air Compressor

Price range: $40.00 through $59.00

Bearing System: Precision Motion Assurance

The bearing system plays an important role in reducing friction, balancing component movement, and regulating overall compressor temperature. Although multiple bearings are distributed at critical positions within the compressor, axial load bearings and radial load bearings are the most important types.

Radial load bearings ensure smooth rotation of compressor rotors and horizontal circular rolling motion while effectively eliminating operating noise. Axial bearings maintain load balance for complementary and perpendicular rotor rotation, ensuring stable operation of the entire compression system. The quality of these precision components directly affects equipment operational smoothness and service life.

Valve System: Key to Precise Control

Suction Valve

Suction valves automatically open and close according to the equipment’s programmed stage settings, ensuring operational efficiency of rotary screw compressor units. To accommodate different design elements for maximizing airflow effects, suction valves offer multiple configuration options. These primarily include poppet valves, ring valves, and plate valves, each featuring unique concentric layer designs to ensure ideal airflow conditions for specific operational types.

Discharge Valve

As the terminal component of the compressor system, discharge valves provide safe and stable release of pure concentrated air. Whether air is released to final storage tanks or connected to pneumatic hoses, discharge valves serve as critical regulatory devices. Regular inspection of these valves and their performance is essential for preventing any type of malfunction.

Related Products

-

1089038450 Solenoid Valve for Atlas Copco Air Compressors

Price range: $70.00 through $200.00 -

1089045110 Solenoid Valve Supplier for Portable Air Compressor

Price range: $50.00 through $100.00 -

1089066821 1089070209 Solenoid Valve for Atlas Copco

Price range: $50.00 through $100.00 -

1089070213 Solenoid Valve for Atlas Copco Air Compressors

Price range: $50.00 through $100.00

Power and Control Systems

Compressor Motor

It’s important to note that the concept of “bigger motor equals better performance” doesn’t always apply to ensuring optimal production efficiency. The horsepower generated and maintained by large motors may introduce efficiency problems. Regular motor testing and efficiency checking are recommended to evaluate overall compressor performance.

System Control

The compressor’s system and stage control can regulate, monitor, and track equipment performance by evaluating functionality and checkpoints across multiple unit characteristics. Specific unit designs may feature internal sensors for automatically shutting down motors upon completion of preset cycles or when storage containers reach saturation. This represents an intelligent technological feature for high-capacity equipment.

Related Products

-

1900071031 Air Compressor Controller for Atlas Copco

Price range: $300.00 through $500.00 -

1900520400 MK5S Controller Touch for Atlas Copco

Price range: $1,171.90 through $1,185.85 -

Atlas Centrifugal Air Compressor Controller 1900071052 Module

Price range: $70.00 through $200.00 -

Atlas Copco 1089958703=1089966049 Combivert F5 Servo

Price range: $100.00 through $150.00

Sealing System: Airtightness Guarantee

Gaskets and Seals

Gaskets and seals employ airtight designs to prevent compressed air leakage. Chamber linings and bearing rings around compression rotors and bearings are as critical as other large or major compressor components. Since they employ oil-lubricated or self-lubricated designs, sliding seals reduce natural friction generated between rotors.

Maintenance Recommendations and Summary

Reliable operation of rotary screw compressors depends on coordinated cooperation among all components. Set up preventive maintenance programs, inspect and replace wear parts regularly, and monitor system parameters. These steps help extend equipment life and boost production efficiency.

Key maintenance includes replacing air and oil filters regularly and checking bearing lubrication status. Monitor valve sensitivity, maintain seal integrity, and adjust control parameters based on usage.

By understanding core components and their maintenance, operators can manage equipment more effectively. This ensures rotary screw compressors perform well in industrial settings. Reliable performance supports long-term enterprise growth.

Related Products

-

0830100809 Air Compressor Safety Valve Parts for Atlas Copco

Price range: $90.00 through $200.00 -

1089038450 Solenoid Valve for Atlas Copco Air Compressors

Price range: $70.00 through $200.00 -

1089045110 Solenoid Valve Supplier for Portable Air Compressor

Price range: $50.00 through $100.00 -

1089066821 1089070209 Solenoid Valve for Atlas Copco

Price range: $50.00 through $100.00

References

- Compressed Air & Gas Institute (CAGI) – Industrial Compressor Standards and Best Practices

https://www.cagi.org/ - American Society of Mechanical Engineers (ASME) – Compressor Technology and Maintenance Guidelines

https://www.asme.org/ - International Organization for Standardization (ISO) – ISO 1217:2009 Displacement Compressors Acceptance Tests

https://www.iso.org/