This article explores the key differences between scroll and screw compressors. We’ll also examine the best applications for each type, helping you settle the debate: Which air compressor is the ideal choice for your facility?“

When selecting an air compressor, the choice between scroll and screw compressors is pivotal. While both serve the fundamental purpose of compressing air, their operational mechanisms, efficiency, maintenance requirements, and suitability for various applications differ significantly. This article uncovers the subtle yet crucial distinctions between these two compressor types, providing insights that many users might overlook.

Contents

Understanding the Basics

Scroll Compressors

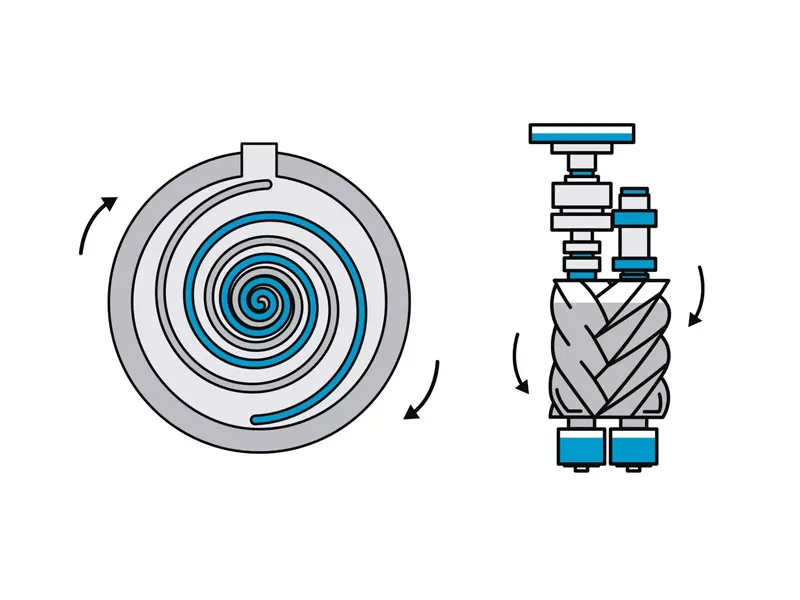

Scroll compressors operate using two interleaving spiral-shaped scrolls. One scroll remains stationary, while the other orbits around it, compressing air in pockets that move towards the center. This design ensures continuous compression with minimal pulsation, resulting in smooth and quiet operation.

Screw Compressors

Screw compressors utilize two helical rotors (male and female) that rotate in opposite directions. As air enters the compressor, it gets trapped between the rotors and is compressed as it moves along the screws. This mechanism is efficient for continuous, high-volume air supply.

Efficiency and Energy Consumption

Scroll Compressors

Scroll compressors are renowned for their energy efficiency, especially in applications with steady load demands. Their design minimizes energy losses, and the absence of valves reduces mechanical complexity, leading to lower energy consumption.

Screw Compressors

Screw compressors are also energy-efficient, particularly in large-scale industrial settings. Modern screw compressors often incorporate variable speed drives (VSDs), allowing the compressor to adjust its output based on demand, thereby optimizing energy usage.

Noise Levels and Vibration

Scroll Compressors

One of the standout features of scroll compressors is their ultra-quiet operation. With noise levels as low as 48 dBA, they are ideal for environments where noise reduction is essential, such as hospitals, laboratories, and offices.

Screw Compressors

Screw compressors tend to be noisier due to the intermeshing rotors. However, advancements in noise-dampening technologies have led to quieter models. Nonetheless, they are generally more suitable for industrial settings where noise is less of a concern.

Maintenance and Reliability

Scroll Compressors

With fewer moving parts, scroll compressors typically require less maintenance. Their simple design reduces the likelihood of mechanical failure, leading to increased reliability and lower maintenance costs.

Screw Compressors

Screw compressors have more complex designs and moving parts, necessitating regular maintenance, including oil changes and component inspections. While they are durable and designed for continuous operation, the maintenance requirements are higher compared to scroll compressors.

Application Suitability

Scroll Compressors

Best suited for applications requiring clean, oil-free air and where noise reduction is critical. Common uses include:

- Medical and dental equipment

- Laboratories

- Electronics manufacturing

- HVAC systems in residential and commercial buildings

Screw Compressors

Ideal for industrial applications demanding continuous, high-volume air supply. Typical applications encompass:

- Manufacturing plants

- Automotive and aerospace industries

- Food and beverage processing

- Chemical and pharmaceutical production

Cost Considerations

Initial Investment

Scroll compressors often have a higher upfront cost due to their precision engineering and oil-free design. However, the lower maintenance and energy costs can offset this over time.

Screw compressors may have a lower initial cost, especially oil-injected models. Yet, the ongoing maintenance and energy expenses should be factored into the total cost of ownership.

Operating Costs

Scroll compressors generally incur lower operating costs, attributed to their energy efficiency and minimal maintenance needs.

Screw compressors, while efficient, may have higher operating costs due to regular maintenance and potential energy losses in variable load conditions.

Environmental Impact

Scroll Compressors

The oil-free operation of scroll compressors ensures no risk of oil contamination, making them environmentally friendly and suitable for applications where air purity is paramount.

Screw Compressors

Oil-injected screw compressors pose a risk of oil contamination if not properly maintained. However, oil-free screw compressors are available, offering clean air solutions for sensitive applications.

Space and Installation

Scroll Compressors

Compact and lightweight, scroll compressors are easy to install in confined spaces. Their quiet operation allows for installation closer to the point of use, reducing the need for extensive piping.

Screw Compressors

Typically larger and heavier, screw compressors require more installation space and may necessitate dedicated compressor rooms, especially in noise-sensitive environments.

Summary Comparison Table

| Feature | Scroll Compressor | Screw Compressor |

| Operation | Orbiting scrolls | Intermeshing helical rotors |

| Noise Level | Very low (≈48 dBA) | Moderate to high |

| Maintenance | Low | Moderate to high |

| Energy Efficiency | High in steady load | High with VSD in variable load |

| Air Purity | Oil-free | Oil-injected or oil-free options |

| Initial Cost | Higher | Lower |

| Operating Cost | Lower | Higher |

| Application Suitability | Medical, labs, HVAC | Industrial, manufacturing |

| Installation Space | Compact | Requires more space |

Conclusion

Choosing between a scroll and screw compressor hinges on your specific application requirements. Scroll compressors excel in environments where noise reduction, air purity, and compactness are critical. In contrast, screw compressors are better suited for industrial settings demanding continuous, high-volume air supply. By understanding these nuanced differences, you can make an informed decision that aligns with your operational needs and budget considerations.

Reference

1.Comprehensive Guide to Scroll vs Screw Compressors https://screwcompressorchina.com/comprehensive-guide-to-scroll-vs-screw-compressors/

2.Scroll vs Screw Compressors: What is the difference? https://www.atlascopco.com/en-ng/compressors/wiki/compressed-air-articles/scroll-vs-screw-compressor

3.What’s the Difference Between a Scroll Vs. Screw Compressor? https://www.energymachinery.com/blog/scroll-compressor-vs-screw-compressor

Related Products

-

Atlas Copco Air Compressors SF8+ SF11+ SF15+ SF17+ SF22+

$10,000.00 – $30,000.00 -

Atlas Copco AQ 15-55 VSD Oil-free Water-Injected Compressors

$10,000.00 – $30,000.00 -

Atlas Copco Oil Free Scroll Air Compressor SF4ff

$3,800.00 – $6,000.00 -

Atlas Copco Screw compressor GX 3 FF

$5,000.00 – $6,000.00