A compressed air system consists of various essential components that ensure efficient, reliable operation. These components work together to produce, treat, and deliver compressed air to the point of use. From powering pneumatic tools to conveying materials in manufacturing processes, each of these parts plays a critical role in guaranteeing the system runs efficiently and stably. Understanding their functions is fundamental to optimizing overall system performance.

Contents

- 1 Air Compressor: The Core of the System

- 2 Aftercooler: Cooling and Initial Moisture Removal

- 3 Industrial Chillers: Precise Temperature Management

- 4 Air Receiver Tank: Storage, Stabilization, and Energy Savings

- 5 Air Dryer: The Key Barrier for System Protection

- 6 Filters: The Guarantee of Purified Air

- 7 Piping: The Arteries for Efficient Distribution

- 8 Conclusion

- 9 Reference Links

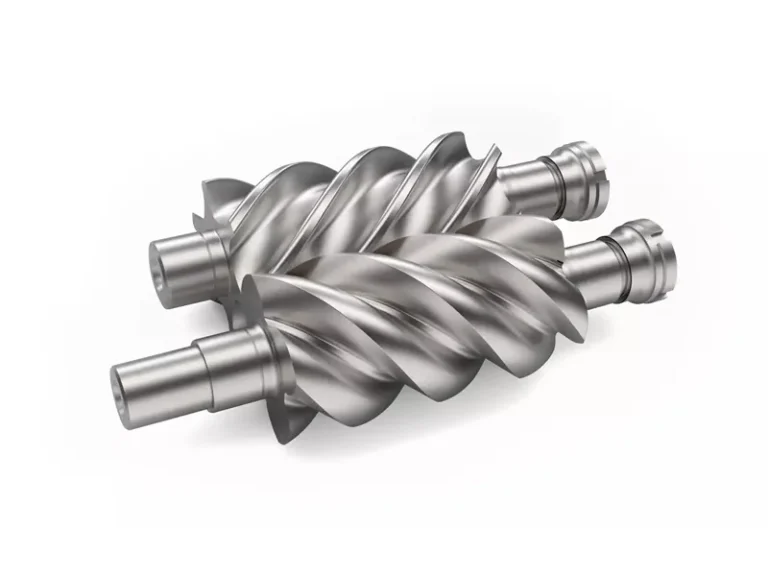

Air Compressor: The Core of the System

As the core of the system, the air compressor’s function is to take in ambient air and compress it to a higher pressure. Whether you’re using a rotary screw air compressor , reciprocating, or centrifugal compressor, the role remains the same—producing compressed air for your application. It is the power source of the system, and its selection and configuration directly determine the system’s energy efficiency and supply capacity.

Aftercooler: Cooling and Initial Moisture Removal

Air temperature rises sharply after compression. The aftercooler is typically installed directly at the compressor outlet, and its primary task is to cool this hot air. As the hot air is cooled, a large portion of its water vapor condenses into liquid, achieving preliminary drying and reducing the load on subsequent purification equipment.

Related Products

-

100% Genuine Atlas Copco 2906032600 Regener Cooler Kit

Price range: $60.00 through $100.00 -

1092002973 Oil Cooler for Atlas Copco Air Compressors

Price range: $150.00 through $400.00 -

1202479800 Cooler Core for Atlas Copco Air Compressors

Price range: $70.00 through $90.00 -

Atlas Cocpo Air Compressor 1092571000 Cooler Oil

Price range: $1,200.00 through $1,800.00

Industrial Chillers: Precise Temperature Management

In some compressed air systems where temperature control is extremely critical or heat generation is very high, Industrial Chillers are used in addition to aftercoolers. The significant heat generated from air compression needs to be managed effectively to improve efficiency and prevent overheating of equipment. Through an independent refrigeration cycle, industrial chillers can precisely cool the compressed air to an optimal set temperature. This not only removes more moisture but also ensures consistent system performance, which is essential for maintaining final product quality and protecting sensitive downstream equipment.

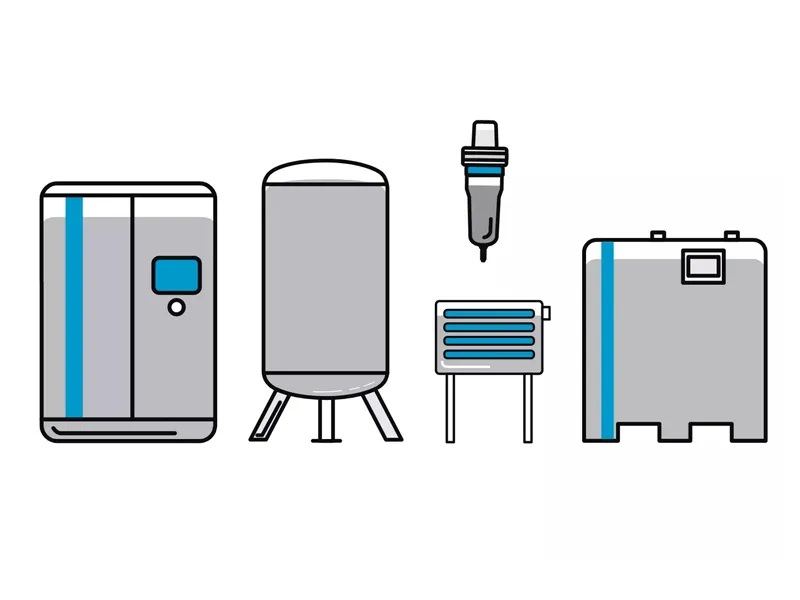

Air Receiver Tank: Storage, Stabilization, and Energy Savings

This tank stores compressed air and helps balance supply with demand, ensuring a steady flow of air while reducing pressure fluctuations within the system. By providing a buffer, the receiver tank can guarantee a stable, continuous airflow, effectively minimizing pressure swings. Furthermore, it reduces the frequent starting and stopping of the compressor, thereby saving energy and extending the equipment’s lifespan.

Air Dryer: The Key Barrier for System Protection

Moisture is a common issue in compressed air systems. An air dryer is used to remove excess moisture from the compressed air, protecting downstream equipment and preventing corrosion. Popular types include refrigerated and desiccant dryers, which lower the air’s dew point to the required level for the process based on different operating principles.

Filters: The Guarantee of Purified Air

Compressed air filters are crucial for removing contaminants like oil, dust, and water from the system. Keeping your air clean ensures the longevity of your tools and the reliability of your system. Even after drying, trace solid particles and oil aerosols may remain. Installing multi-stage precision filters guarantees that the air delivered to the point of use is clean.

Related Products

-

100% Genuine Atlas Copco Oil Filter 1614874799=1614874700

Price range: $100.00 through $150.00 -

100% Original Atlas Copco Centrifuge Oil Filter 1621808500

Price range: $50.00 through $90.00 -

100% Original Ingersoll Rand 54672654 Coolant Oil Filter

Price range: $20.00 through $26.00 -

1613610590 Oil Filter for Atlas Copco Air Compressors

Price range: $30.00 through $50.00

Piping: The Arteries for Efficient Distribution

The piping system distributes compressed air to various points in your facility. Using high-quality materials like aluminum or stainless steel prevents air leaks and reduces pressure drops, ensuring your system runs at peak efficiency. A well-designed piping network is fundamental to guaranteeing efficient transmission of compressed air from source to end-point.

Conclusion

In summary, a successful compressed air system is the result of all its parts working in harmony. From the core air compressor and the storage receiver tank to the aftercoolers, chillers, dryers, and filters responsible for cooling, drying, and purification, and finally the piping network for distribution—each of these compressed air system components, including chillers, plays a critical role in ensuring your system operates effectively, delivering the required air pressure and quality.

We are Seadweer, a Atlas Copco supplier from China, specialize in air compressors and spare parts, vacuum systems, blower systems, Power Generators , Lighting towers for brands such as Atlas Copco, Quincy, Ingersoll Rand, Chicago Pneumatic, Sullair, etc. Our prices will be very competitive because Atlas Copco has established the world’s second largest factory in Wuxi, China, second only to Belgium, we can place orders directly from this factory.Should you have any requirements, kindly provide the part numbers and serial numbers, and we will promptly prepare a quotation for you.

Reference Links

- U.S. Department of Energy – Provides best practices and resources on improving the energy efficiency of compressed air systems. https://betterbuildingssolutioncenter.energy.gov/better-plants/compressed-air

- Compressed Air & Gas Institute (CAGI) – As the leading authority in the compressed air industry, CAGI provides technical standards, educational materials, and unbiased equipment performance data. https://www.cagi.org

- Compressed Air Challenge – A collaborative organization of government agencies, utilities, manufacturers, and experts dedicated to providing product-neutral information and training to help industries optimize their compressed air systems. https://www.compressedairchallenge.org