Atlas Copco Supports Kingdomway in Becoming a Leading Producer of Nutritional Fortifiers, Enhancing Quality of Life Through Better Health

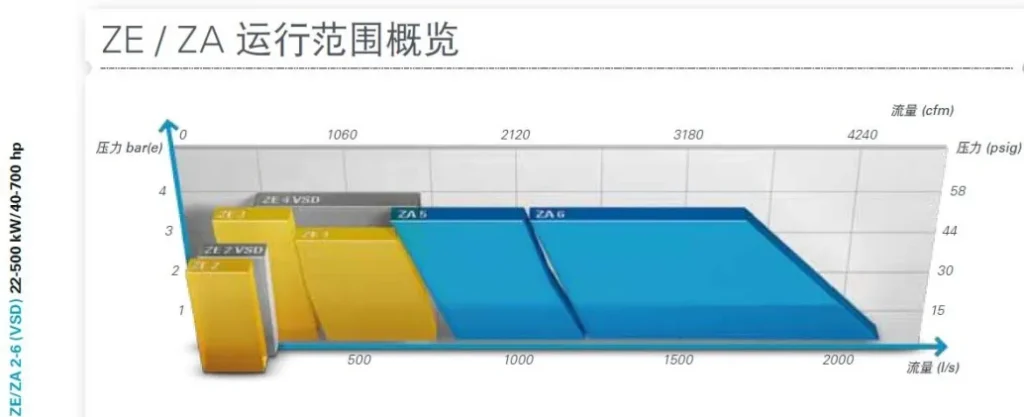

As a global leader in air compressors, Atlas Copco offers a comprehensive range of low-pressure oil-free air solutions. Typically, compressed air at 1.5 to 4 barG is considered low-pressure air, which is an essential power source in many industrial processes. It plays a crucial role in fields such as pharmaceutical fermentation, pneumatic conveying, glass manufacturing, and flue gas desulfurization (in thermal power plants).

Contents

A Longstanding Partnership Between Atlas Copco and Kingdomway

To better serve customers and further develop applications in the pharmaceutical fermentation sector, Atlas Copco’s low-pressure sales and technical team visited a key fermentation customer in September—the Kingdomway Group’s production facility in Hohhot, Inner Mongolia.

Kingdomway is a renowned global supplier of nutritional fortifiers, operating four production sites in Xiamen and Hohhot. The company manufactures five major product lines: Coenzyme Q10, microalgae DHA, plant-based ARA, Vitamin A, and Vitamin D3. Kingdomway’s products serve diverse industries including pharmaceuticals, health supplements, food, cosmetics, and animal feed, while reaching dozens of countries and regions through global exports. The company actively enhances quality of life by driving innovation in nutritional and biopharmaceutical solutions.

From the very beginning, Kingdomway chose Atlas Copco air compressors and has remained a loyal customer ever since. Mr. Jiang Jicheng, Engineering Director at Kingdomway, commented,

“For more than ten years, we’ve been extremely satisfied with the performance and after-sales service of Atlas Copco compressors. They provide reliable, stable power for our 24/7 production needs.”

When Kingdomway’s Hohhot site launched its fermentation production line in 2004, they once again selected Atlas Copco’s low-pressure air compressors. The recent expansion of new production lines prompted us to purchase 12 additional units, increasing our facility’s total to 16 Atlas Copco low-pressure compressors that now run stably.

To meet the specific demands and technical requirements of the new fermentation line, Atlas Copco’s technical sales team recommended the ZA6G-300 model oil-free screw compressor.

“This production line uses 16 fermentation tanks, with pre-installed air filters, water separators, and other devices that lead to pressure drops and air losses. To maintain air pressure at 2–2.5 bar in the fermentation tanks, we designed an input pressure of 3 bar to ensure stable operation,” said Yang Mingzhe, Senior Sales Engineer at Atlas Copco’s Oil-Free Air Division.

Mr. Jiang added,

“Atlas Copco’s customized design, along with the stability, safety, and flexibility of their equipment, gives us great confidence. For products like Coenzyme Q10, DHA, and ARA—used in baby formula and health supplements—the fermentation process is key. It requires a continuous supply of low-pressure air at 2 bar to feed oxygen and enable microbial growth. Because the compressed air is directly involved in the process, its purity is critical. Even trace amounts of oil can kill microbes, contaminate the final product, and endanger consumer health. That’s why absolute oil-free air is our top priority. Atlas Copco, as a leader in oil-free compressor technology, has been essential to our uninterrupted and safe production over the years.”

ZA Low-Pressure Oil-Free Compressors Empower Fermentation Efficiency

Every ZA/ZE series oil-free screw compressor from Atlas Copco is designed and manufactured to meet ISO 9001 standards. The compressors feature world-leading oil-free screw technology, with a unique double-layer Teflon coating that minimizes rotor clearance to maximize efficiency. This coating also forms a profile during operation to avoid hard contact between rotors, increasing lifespan and corrosion resistance. The cooling jacket ensures the air end operates at optimal temperature, improving both reliability and efficiency. The advanced rotor bearings deliver consistent performance under various load conditions.

For biopharmaceutical fermentation, oil-free screw technology ensures stable output pressure, minimal sensitivity to ambient temperature and humidity, and excellent adaptability to fluctuations in pressure and flow—making it a highly efficient and reliable source of compressed air for continuous production. Moreover, Atlas Copco’s oil-free series compressors are among the few auxiliary production devices exempt from inspection under China’s Good Manufacturing Practice (GMP) guidelines.

Atlas Copco’s ZA/ZE oil-free compressors are certified to ISO 8573-1 CLASS 0 (2001), which ensures zero risk of oil contamination, zero risk of unsafe or defective product output, and zero risk of downtime-related losses. As an industry leader committed to meeting the strictest customer demands, Atlas Copco sought type testing from the globally respected TÜV Institute. Using the most rigorous test methods available, TÜV tested the compressors across various temperatures and pressures for all possible forms of oil contamination. No trace of oil was found in the output air. As a result, Atlas Copco became the first manufacturer of compressors and blowers to receive CLASS 0 certification—and even exceeded the ISO 8573-1 CLASS 0 requirements.

Ying Junchao, Atlas Copco’s Low-Pressure Product Application Specialist, commented:

“Our low-pressure R&D team is driven by innovation and quality. We focus on delivering excellent customer service and support. During the customer’s usage of Atlas Copco products, our professional team provides regular or on-demand on-site services to ensure stable and efficient operation. Our goal is to provide high-quality power solutions that help customers succeed.”

The ZA/ZE series low-pressure compressors from Atlas Copco represent the perfect blend of cutting-edge technology and rugged design. With customizable features tailored to specific production environments, they offer clients bespoke low-pressure air solutions to meet the most demanding needs.

Atlas Copco: A Global Leader Driving Sustainable Productivity

Atlas Copco is a globally leading industrial group in the fields of compressors, expanders and air treatment systems, construction and mining equipment, power tools, and assembly systems. Through innovative products and services, Atlas Copco provides a wide range of solutions to achieve sustainable productivity.

Founded in 1873 and headquartered in Stockholm, Sweden, the Atlas Copco Group operates in more than 180 countries and regions worldwide. In 2012, the company had approximately 39,800 employees and achieved revenues of SEK 90.5 billion (EUR 10.5 billion).

The Compressor Technique business area of Atlas Copco offers industrial compressors, vacuum solutions, gas and process compressors, expanders, air and gas treatment equipment, as well as air management systems. With a global presence, it also provides specialized rental services. This business area continually innovates to deliver sustainable productivity to industries such as manufacturing, oil and gas, and processing. Its main R&D and production centers are located in Belgium, Germany, the United States, China, and India.

Related Products

-

Atlas Copco Air Compressors SF8+ SF11+ SF15+ SF17+ SF22+

Price range: $10,000.00 through $30,000.00 -

Atlas Copco AQ 15-55 VSD Oil-free Water-Injected Compressors

Price range: $10,000.00 through $30,000.00 -

Atlas Copco Oil Free Scroll Air Compressor SF4ff

Price range: $3,800.00 through $6,000.00 -

Atlas Copco Screw compressor GX 3 FF

Price range: $5,000.00 through $6,000.00