Air compressors are the workhorses of numerous industries, providing the power behind a vast array of tools and processes. From powering pneumatic tools in manufacturing to enabling critical operations in healthcare and maintaining comfortable environments in HVAC systems, their reliable performance is essential. However, like any mechanical equipment, air compressors are susceptible to wear and tear, leading to the need for repair. Understanding the intricacies of air compressor repair is crucial for businesses to maintain operational efficiency, minimize downtime, and make informed decisions about the longevity of their equipment.

This article delves into common air compressor repair projects, the importance of timely maintenance, and the factors to consider when repairing or replacing a compressor.

Contents

Common Air Compressor Repair Projects

The nature of air compressor repairs can vary widely depending on the type of compressor, its age, and the specific issue at hand. Some of the most common repairs include:

- Leak Detection and Repair: Air leaks are a significant source of inefficiency and can lead to a compressor working harder than necessary. Repairing leaks often involves replacing worn hoses, fittings, or seals.

- Valve Repair or Replacement: Valves play a crucial role in regulating airflow. Worn or damaged inlet and outlet valves can significantly impact compressor performance. Repair might involve cleaning or replacing valve components.

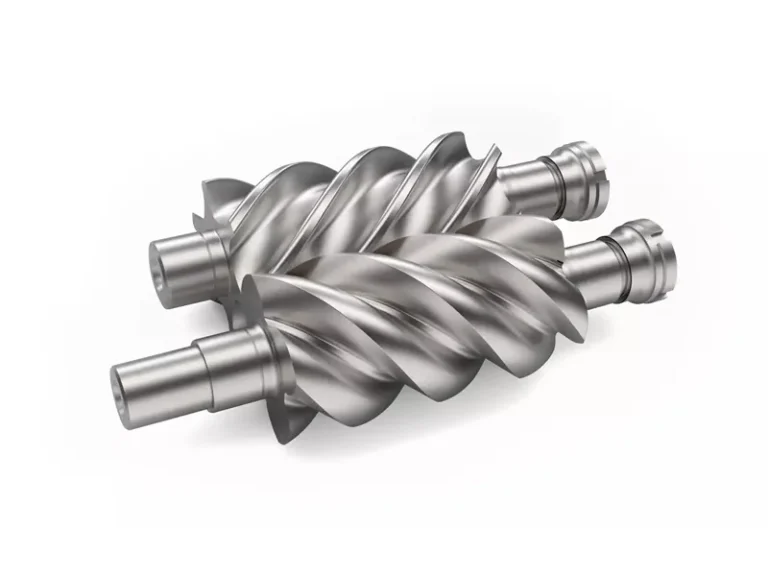

- Air End Overhaul: The air end is the heart of a screw compressor, where the air is compressed. Over time, the rotors and bearings within the air end can wear out, requiring a complete overhaul or replacement of the air end.

- Motor Repair or Replacement: The electric motor that drives the compressor can experience various issues, from bearing failures to winding problems. Depending on the severity, the motor might be repairable, or a replacement might be necessary.

- Lubrication System Maintenance: Proper lubrication is vital for the longevity of an air compressor. Repairs related to the lubrication system might involve fixing leaks, replacing filters, or addressing issues with the oil pump.

- Cooling System Repair: Overheating can be detrimental to a compressor. Repairs to the cooling system could involve cleaning or replacing coolers, fixing fan issues, or addressing coolant leaks in liquid-cooled models.

- Control System Troubleshooting: Modern air compressors often have sophisticated control systems. Troubleshooting and repairing issues with pressure sensors, controllers, or electrical wiring might require specialized expertise.

- Filter Replacement: While technically maintenance, neglecting air filters, oil filters, and separators can lead to significant problems over time, necessitating more extensive repairs. Regular filter replacement is crucial.

The Importance of Timely Air Compressor Repair

Addressing air compressor issues promptly is essential for several reasons. Firstly, failing to address small problems can lead to their rapid escalation into major failures, potentially causing extensive damage to critical components. By undertaking timely repairs, businesses can prevent further deterioration of their equipment, resulting in significant cost savings in the long run.

Secondly, a malfunctioning compressor invariably operates at a reduced efficiency level. This inefficiency translates directly into increased energy consumption and consequently, higher operational costs. By promptly repairing identified issues, the compressor’s optimal efficiency can be restored, leading to a reduction in energy waste and lower utility bills. Furthermore, the reliability of the compressed air supply is directly impacted by the condition of the compressor. An unreliable unit can cause unexpected downtime, disrupting production schedules and potentially leading to substantial financial losses. Timely repairs play a crucial role in maintaining the consistent and dependable operation of the air compressor.

Finally, both the longevity and safety of the air compressor are significantly influenced by the attention given to timely repairs. Regular air compressor maintenance combined with addressing issues as they arise contributes directly to extending the overall lifespan of the equipment, maximizing the return on investment for businesses. Additionally, certain compressor malfunctions can create potential safety hazards for personnel. Addressing these issues without delay ensures a safe working environment for all involved.

When to Consider Repair vs. Replacement

While repairing an air compressor is often the more immediate and seemingly cost-effective solution, there are situations where replacement might be a more prudent long-term decision. Factors to consider include:

| Factor | Considerations for Repair | Considerations for Replacement |

| Age of the Compressor | If the compressor is relatively young and the issue is not indicative of widespread wear, repair is likely a cost-effective option to extend its service life. | If the compressor is old and beyond its typical lifespan, repair might only be a temporary fix, and replacement offers a more reliable and potentially energy-efficient long-term solution. |

| Cost of Repair | If the estimated cost of repair is relatively low compared to the cost of a new compressor and the issue is not recurring, repair is often the most economical choice. | If the estimated cost of repairing a major component is a significant portion of the price of a new compressor, replacement might be the more prudent financial decision, especially considering potential future issues. |

| Energy Efficiency | If the compressor is already relatively energy-efficient for its age, repairing a minor issue won’t significantly impact energy consumption. | If the older compressor is significantly less energy-efficient than modern alternatives, replacement can lead to substantial long-term savings on electricity bills, offsetting the initial investment. |

| Repair History and Reliability | If the compressor has generally been reliable with only occasional minor repairs, addressing the current issue is likely sufficient to maintain its operational status. | If the compressor has a history of frequent and costly breakdowns, replacement can provide greater reliability and reduce the likelihood of future disruptions and repair expenses. |

| Changing Operational Needs | If the current compressor still meets the business’s operational requirements in terms of pressure and volume, repair is a suitable option to restore its functionality. | If the business’s compressed air needs have grown beyond the capacity of the current compressor, replacement with a unit that meets the new demands is necessary. |

Conclusion

Air compressor repair is an inevitable aspect of owning and operating these vital pieces of equipment. By understanding the common signs of malfunction, the types of repairs that might be needed, and the importance of addressing issues promptly, businesses can ensure the continued optimal performance and longevity of their air compressors. While repair is often the most immediate solution, a careful evaluation of factors such as age, repair costs, energy efficiency, and reliability is necessary to determine whether replacement might be a more cost-effective and sustainable approach in the long run. Choosing a reputable and experienced air compressor repair service provider is crucial for receiving quality workmanship and minimizing disruption to operations. Ultimately, a proactive approach to maintenance and timely attention to repair needs will ensure a reliable and efficient compressed air supply for years to come.

Welcome to choose Atlas Copco supplier —— Seadweer to provide you with various types of Atlas Copco air compressors, including oil-injected screw compressors, oil-free vortex compressors, oil-free water-lubricated compressors, and so on, if you need to replace your air compressor. Atlas Copco operates a manufacturing facility in Wuxi, China. We are able to offer cost-competitive 100% original parts and 100% genuine guarantee air compress directly sourced from the factory.

Related Products

-

Atlas Copco Air Compressor G-Series

Price range: $8,000.00 through $10,000.00 -

Atlas Copco Air Compressor GA11+ – 30 FF

Price range: $880.00 through $1,800.00 -

Atlas Copco Air Compressor GA110VSD

Price range: $6,800.00 through $10,000.00 -

Atlas Copco Air Compressor GA132

Price range: $6,800.00 through $10,000.00

Reference

1.Should I Repair or Replace My Broken Air Compressor? – https://www.atlascopco.com/en-sg/compressors/air-compressor-blog/repair-or-replace-air-compressor