Discover the role of the air compressor head, also known as the airend, in your rotary screw compressor. This vital component is often described as the “heart” of the machine. Without it, no compression happens, and the system becomes nothing more than a motor-driven housing.

In this article, we will explore:

- What the air compressor head is

- How it works inside a rotary screw compressor

- Why it is the most critical component

- How to maintain and extend its lifespan

By the end, you’ll understand why proper care of the air compressor head ensures efficiency, reliability, and long-term value for your industrial applications.

Contents

- 1 What Is an Air Compressor Head?

- 2 How the Air Compressor Head Works

- 3 Oil-Injected vs. Oil-Free Air Compressor Heads

- 4 Why the Air Compressor Head Is the Most Critical Component

- 5 Common Problems with Air Compressor Heads

- 6 Maintenance Tips for the Air Compressor Head

- 7 When to Repair or Replace the Air Compressor Head

- 8 Conclusion

- 9 Related Products

What Is an Air Compressor Head?

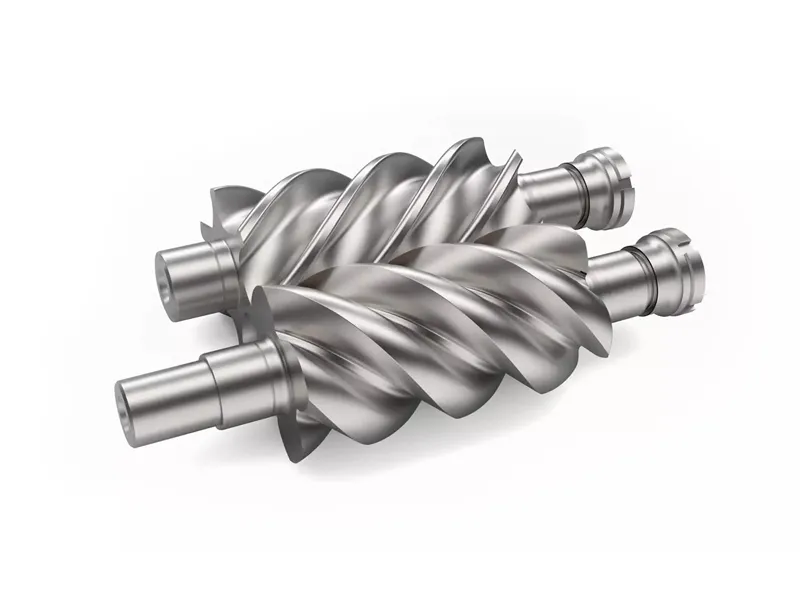

The air compressor head—or air end—is the core compression unit within a rotary screw compressor. It consists of two precisely machined helical rotors, one male and one female, enclosed in a casing.

When these rotors spin, air enters through the inlet valve, gets trapped between the rotor lobes, and is gradually compressed as the rotors turn. Finally, the compressed air exits the housing through the discharge port.

This design allows rotary screw compressors to deliver a continuous flow of compressed air without pulsation, making them ideal for industrial environments that demand 24/7 reliability.

How the Air Compressor Head Works

The working principle of the air compressor head is straightforward yet highly efficient:

- Air Intake – Ambient air is drawn into the airend through an inlet valve.

- Air Trapping – The air fills the cavities between the rotors.

- Compression – As the rotors turn, the cavities shrink, compressing the air volume.

- Discharge – The compressed air is expelled through the outlet port, ready for downstream use.

This process produces a constant airflow at a given volume (CFM) while allowing pressure to vary as needed. Unlike piston compressors, the air compressor head ensures smooth, vibration-free operation.

Oil-Injected vs. Oil-Free Air Compressor Heads

There are two main types of air compressor heads: oil-injected and oil-free. Each has specific advantages depending on your application.

| Type of Air Compressor Head | How It Works | Advantages | Typical Applications |

|---|---|---|---|

| Oil-Injected | Oil is injected into the airend to lubricate, seal, and cool the rotors. The oil is later separated from the compressed air. | Higher efficiency, better cooling, longer lifespan, higher pressure ratios (up to 13:1). | General manufacturing, automotive, heavy industry. |

| Oil-Free | No oil is used inside the compression chamber. Extremely tight tolerances and advanced cooling keep rotors separated. | Delivers 100% oil-free air, essential for sensitive industries; environmentally cleaner. | Food & beverage, pharmaceuticals, electronics, healthcare. |

Choosing the right air compressor head depends on whether your operations can tolerate trace oil or demand certified oil-free compressed air.

Why the Air Compressor Head Is the Most Critical Component

The airend plays the most important role in the overall performance of rotary screw air compressors. Here’s why:

- Direct Impact on Efficiency

The condition of the air compressor head determines how much energy is needed to produce compressed air. Worn rotors cause internal leakage, forcing the motor to work harder and consume more power. - Determinant of Output Quality

Airflow (CFM), pressure stability, and air purity are all tied to the performance of the airend. - Longevity of the Machine

A well-maintained air compressor head can run for 40,000–60,000 hours before requiring a major overhaul. Neglect, however, shortens this drastically. - Cost Consideration

Since the airends is the most expensive air compressor parts, replacing or rebuilding it often represents the biggest investment. Protecting it through maintenance saves significant costs in the long run.

Common Problems with Air Compressor Heads

Even though airends are robust, certain issues can arise over time:

- Reduced CFM output – Often caused by rotor wear or internal leakage.

- Increased energy consumption – A sign that the compressor is working harder due to inefficiencies in the airend.

- Unusual noise or vibration – May indicate bearing failure or rotor misalignment.

- Overheating – Could result from insufficient cooling or oil circulation problems.

- Oil carryover (for oil-injected heads) – Suggests wear in seals or inefficient oil separation.

Recognizing these early symptoms helps prevent costly breakdowns.

Maintenance Tips for the Air Compressor Head

To maximize the lifespan and efficiency of your compressor head, follow these key practices:

- Regular Oil and Filter Changes

- For oil-injected heads, replace oil filters according to the manufacturer’s schedule.

- Fresh oil ensures proper lubrication and cooling.

- Monitor Bearing Condition

- Bearings support the rotors and maintain clearances.

- Worn bearings can cause catastrophic rotor damage.

- Clean Cooling Systems

- Whether oil-cooled or water-cooled, heat must be managed effectively.

- Keep cooler free from dust and debris.

- Check for Leaks and Wear

- Inspect seals, gaskets, and connections.

- Even small leaks reduce efficiency and increase energy costs.

- Schedule Professional Overhauls

- Most rotary screw compressor airends require major servicing after 40,000–60,000 hours.

- Professional rebuilds restore efficiency and extend life.

When to Repair or Replace the Air Compressor Head

Eventually, every airend will reach the end of its service life. The decision to repair or replace depends on:

- Age and Operating Hours – Units approaching 60,000+ hours often require complete rebuilds.

- Severity of Damage – Minor wear may be resolved with new bearings and seals, while major rotor damage often calls for replacement.

- Cost vs. Value – If repairs approach the price of a new compressor head, replacement is usually the smarter choice.

Many manufacturers and service providers also offer remanufactured airends, which provide a cost-effective solution while maintaining performance standards.

Conclusion

The air compressor head, or airend, is truly the core of rotary screw compressors. It performs the fundamental task of compressing air, determines the efficiency of the machine, and represents the single most valuable part of the system.

By understanding how it works, recognizing its importance, and applying the right maintenance practices, you ensure reliable compressed air supply for your operations.

Whether your system uses an oil-injected or oil-free airend, the key to long-term performance lies in regular care, early detection of problems, and timely servicing.

Related Products

-

100% Genuine Atlas Copco 1616590483 O.F.S. M-23 Air End

Price range: $20,000.00 through $30,000.00 -

100% Original OIS-K25 1616646680 Air End for Atlas Copco

Price range: $1,500.00 through $1,800.00 -

1303032080 Air End S67 for Atlas Copco Compressor

Price range: $1,000.00 through $1,300.00 -

1616724880=1616724890 Air End for Atlas Copco AQ37-55

Price range: $25,342.10 through $30,612.89