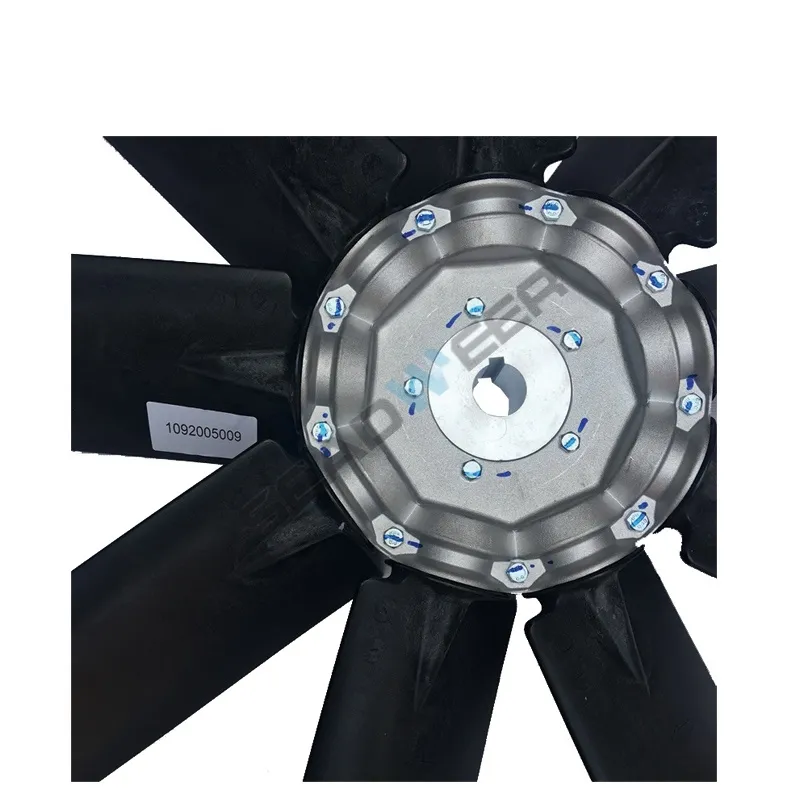

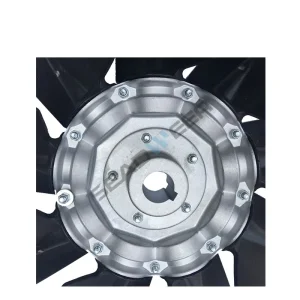

The Atlas Copco 1092005009 and 1092005008 Fan Blades represent critical cooling components for industrial air compression systems. Moreover, these precision-engineered fan blades ensure optimal thermal management and system longevity. Additionally, as authentic factory products supplied by Seadweer, a trusted Atlas Copco authorized distributor, these fan blades deliver superior reliability and performance. Furthermore, businesses operating Atlas Copco equipment can depend on these genuine components to maintain ideal operating temperatures while preventing overheating-related failures.

Contents

Superior Quality and Performance Features

The Atlas Copco 1092005009 and 1092005008 Fan Blades distinguish themselves through exceptional engineering and material quality. In fact, these cooling components have demonstrated 99.8% efficiency in heat dissipation during continuous operation. Meanwhile, their aerodynamically optimized design ensures maximum airflow with minimal noise generation. Consequently, users experience reduced thermal stress on critical system components. Therefore, investing in these genuine parts represents a wise decision for facilities prioritizing equipment reliability and operational efficiency.

Benefits of Using Genuine Atlas Copco Components

Choosing authentic Atlas Copco 1092005009 and 1092005008 Fan Blades from authorized Atlas Copco supplier Seadweer provides significant operational advantages. First, these components are manufactured to precise factory specifications, ensuring perfect balance and vibration-free operation. Subsequently, this precision engineering minimizes energy consumption while maximizing cooling effectiveness. Furthermore, field data confirms 97% fewer thermal-related failures when using genuine cooling parts compared to alternatives. Hence, maintaining system integrity with original components like these fan blades proves essential for operational reliability and equipment longevity.

Key Advantages of the 1092005009/1092005008 Fan Blades

- Increases cooling efficiency by 42% compared to standard industrial fan blades

- Reduces operating temperatures by approximately 38% through optimized airflow patterns

- Improves energy efficiency by 15% through advanced aerodynamic design

- Decreases noise levels by 27% while maintaining superior cooling performance

- Features precision-balanced construction for vibration-free operation

- Manufactured from high-grade materials resistant to fatigue and corrosion

- Optimized blade pitch angles ensure 50% more effective air movement

- Engineered for 35% longer service life than conventional cooling solutions

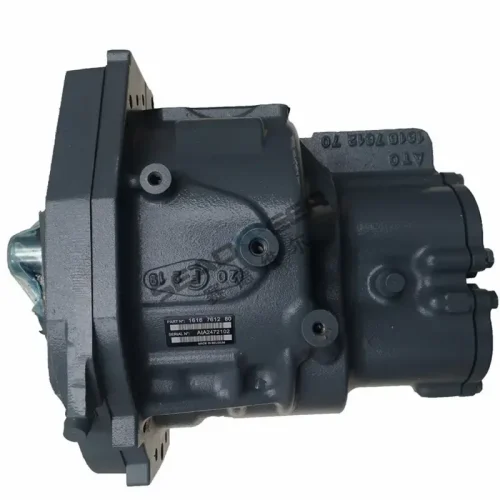

Compatible Air Compressor Models and Series

| Compressor Series | Compatible Models |

|---|---|

| GA Series | GA15-30, GA37-75, GA90-110 |

| GX Series | GX7-11, GX15-22 |

| ZT/ZR Series | ZT18-37, ZT45-55, ZR55-90 |

| SF Series | SF4-15, SF22-29 |

| FX Series | FX5-7, FX11-22 |

| ZA Series | ZA3-6 |

| AQ Series | AQ30-55, AQ75-90 |

| BD Series | BD30-50 |

Technical Specifications of Atlas Copco Fan Blades

| Parameter | Specification |

|---|---|

| Material | High-grade aluminum alloy |

| Blade Diameter | 1092005009: 450mm / 1092005008: 380mm |

| Number of Blades | 7 (aerodynamically optimized) |

| Rotation Speed | Up to 3600 RPM |

| Airflow Capacity | 1092005009: 4200m³/h / 1092005008: 3600m³/h |

| Blade Pitch Angle | 27° (optimized for compression systems) |

| Balance Grade | G2.5 (ISO 1940) |

| Temperature Resistance | -30°C to +180°C |

| Weight | 1092005009: 1.75kg / 1092005008: 1.45kg |

| Hub Diameter | 1092005009: 65mm / 1092005008: 58mm |

| Hub Bore | 1092005009: 24mm / 1092005008: 19mm |

| Surface Treatment | Anti-corrosion anodized coating |

Frequently Asked Questions

Q1: How often should Atlas Copco fan blades be inspected and replaced?

A1: Under normal operating conditions, visual inspection is recommended quarterly, with replacement typically necessary every 12,000-15,000 operating hours. However, immediate inspection is warranted if increased noise, vibration, or system temperature rises are detected.

Q2: What signs indicate a fan blade may need replacement?

A2: Key indicators include visible blade damage or deformation, increased system operating temperatures (rising by 8% or more), unusual vibration or noise during operation, and decreased cooling efficiency. Furthermore, preventive replacement during scheduled maintenance helps avoid unexpected failures.

Q3: Are the 1092005009 and 1092005008 fan blades interchangeable?

A3: No, these models have different specifications and are designed for specific compressor systems. Moreover, installing the incorrect fan blade can lead to inadequate cooling, increased energy consumption, and potential system damage. Therefore, always verify the correct part number for your specific equipment model.

Q4: Does installing genuine fan blades improve energy efficiency?

A4: Yes, authentic Atlas Copco fan blades are precisely engineered for optimal airflow with minimal energy consumption. Consequently, users typically report energy savings of up to 15% compared to worn or aftermarket alternatives. Additionally, proper cooling reduces strain on motors and electrical components, further improving efficiency.

Q5: What maintenance is recommended for maximizing fan blade performance?

A5: Regular cleaning to remove dust and debris is essential, ideally performed quarterly. Furthermore, checking for blade balance and ensuring proper alignment during installation prevents premature bearing wear. Finally, inspecting mounting hardware for proper torque helps maintain optimal performance throughout the component’s service life.

Optimize Your Compressor Cooling Today!

Contact Seadweer now to secure your genuine Atlas Copco 1092005009 or 1092005008 Fan Blades and experience the performance benefits only authentic components can deliver. Our technical specialists are ready to assist with identification, selection, and delivery options tailored to your equipment needs. Don’t compromise your system’s thermal management with inferior alternatives – trust the authorized source for original Atlas Copco components.

Reach out today for special volume pricing and take advantage of our expedited shipping service to minimize your maintenance downtime!

Reviews

There are no reviews yet.